Reed opening and weft inserting auxiliary mechanism for air jet loom

A technology of air-jet looms and auxiliary mechanisms, which is applied to looms, textiles, textiles, and papermaking, etc. It can solve the problems of unsmooth weft insertion, unstable and reliable machine operation, and low weft insertion efficiency, so as to achieve smooth air flow and smooth loom Stable and reliable operation and smooth weft insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

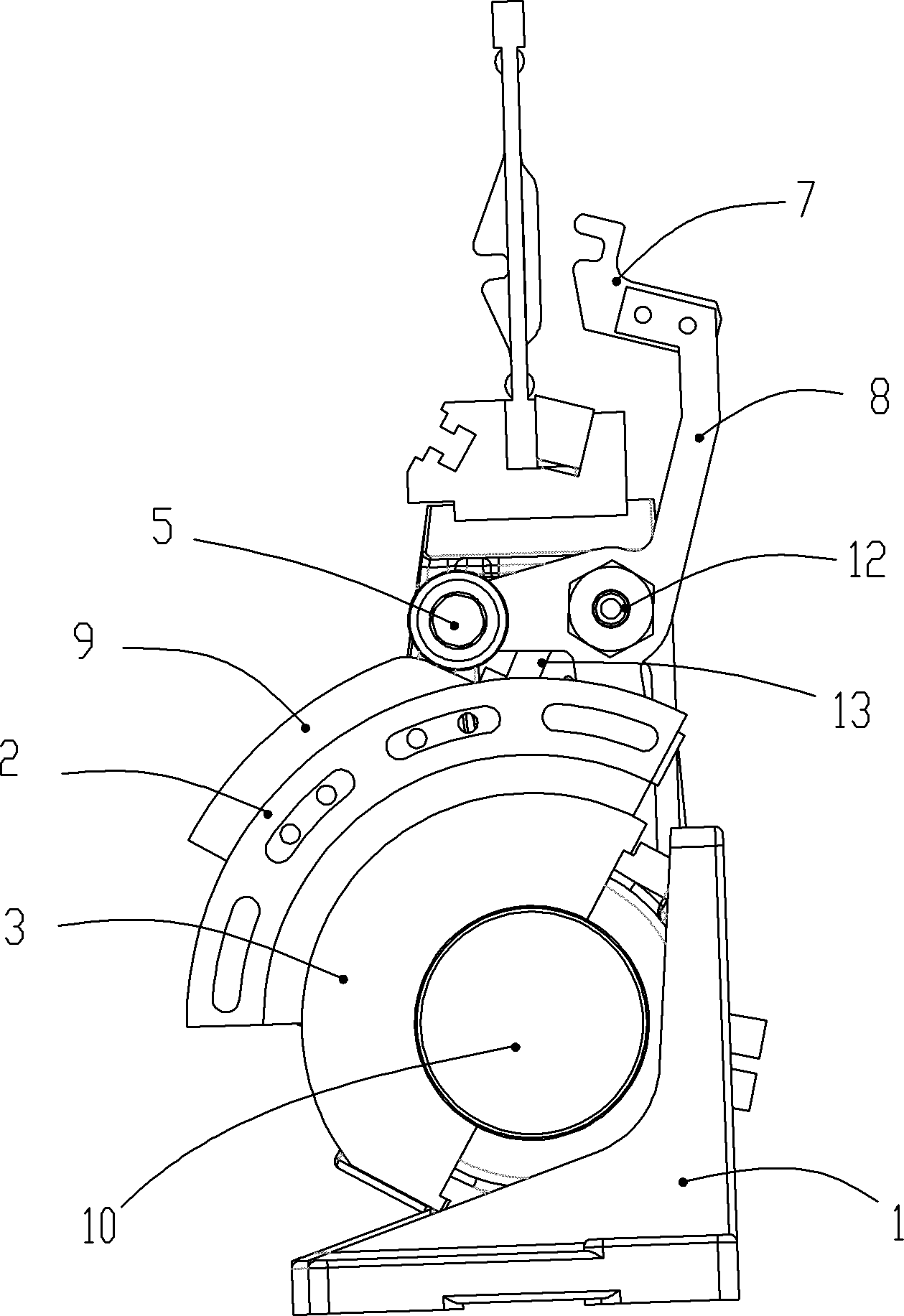

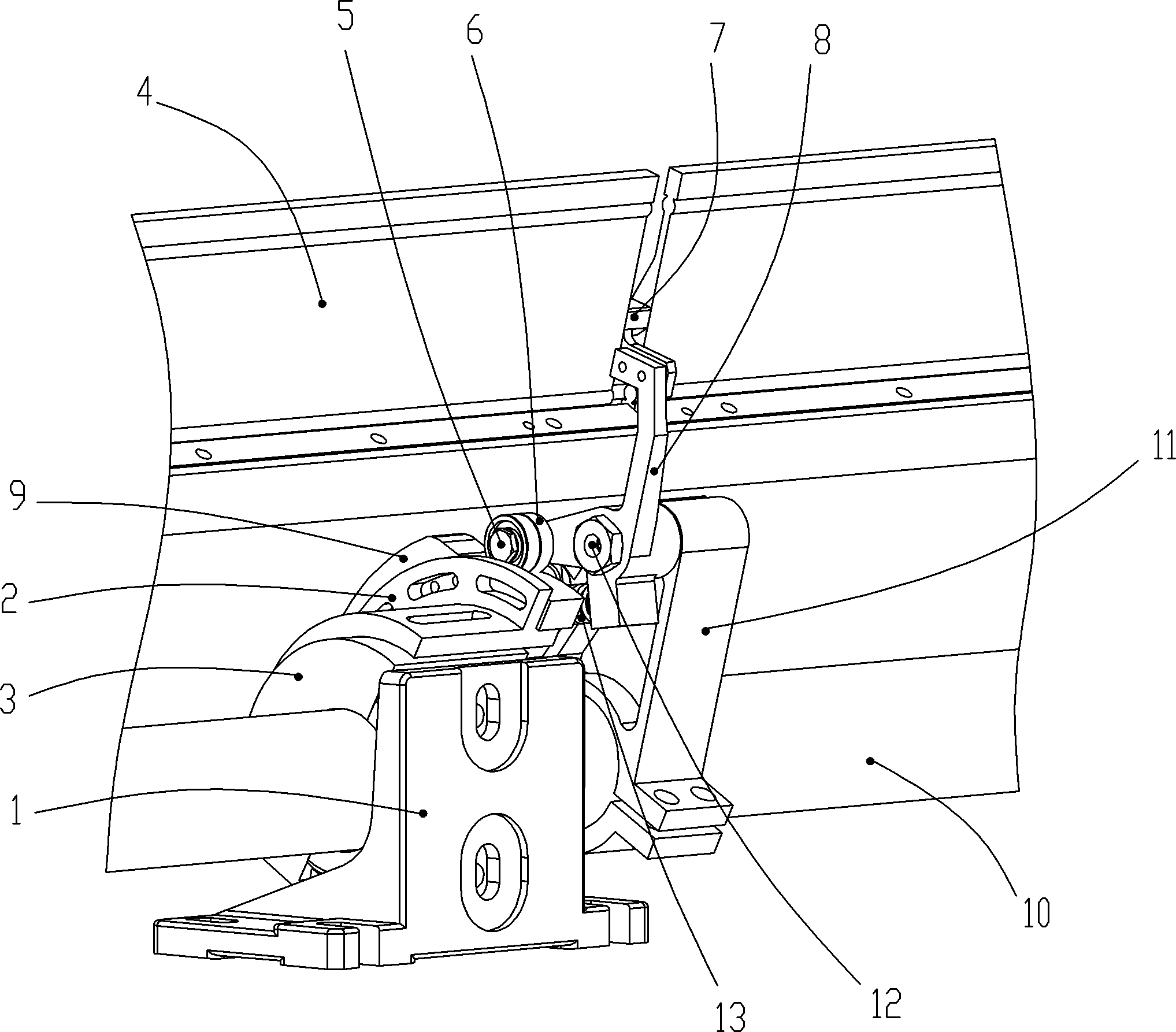

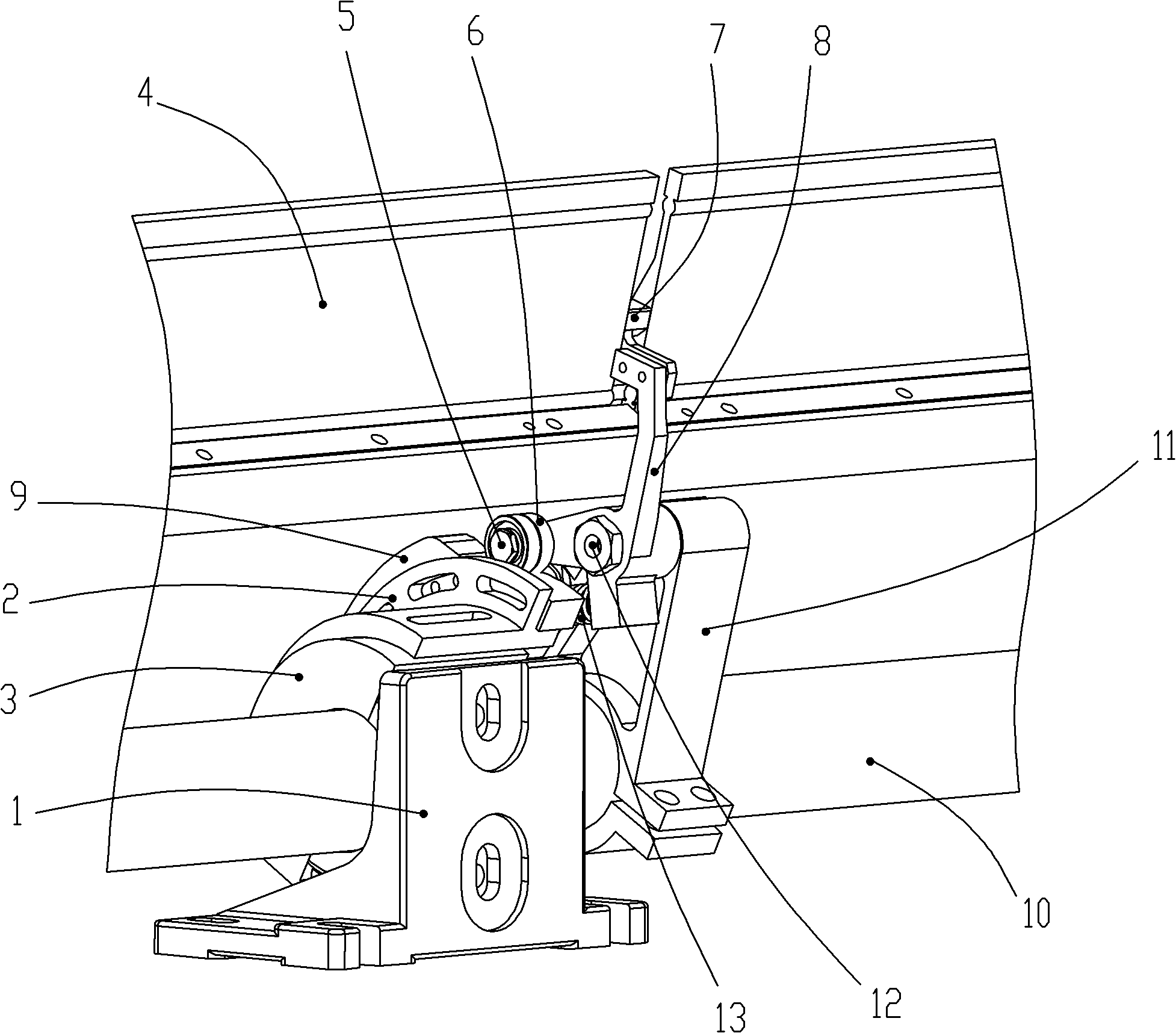

[0016] to combine figure 1 and figure 2 , an auxiliary mechanism for reed opening and weft insertion for an air-jet loom, including a bearing housing assembly 1, a cam 9, a swing arm 8 and an auxiliary reed groove 7. The above-mentioned bearing block assembly is fixed on the frame of the air-jet loom, and is emptied on the beating shaft 10 of the air-jet loom. In this way, when the beating shaft is rotating, the bearing block assembly remains still; A cam support block 3 is arranged on the assembly, and the cam is connected to the cam support block through the cam connection block 2 . Above-mentioned swing arm is fixed on the beat-up shaft by swing arm support 11, and one end of swing arm is provided with roller 6, and roller 6 can be connected on the swing arm by roller shaft 5, and roller 6 cooperates with cam, and auxiliary reed groove is connected on swing arm on the other end. The swing arm is connected to the swing arm bracket through the pin shaft 12, and the swing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com