Exhaust device for decorating machine

A technology for an exhaust device and a printing machine, which is used in printing machines, printing machines, general parts of printing machines, etc., can solve the problems of limited ventilation, increase production costs, and discomfort for operators, and achieve uniform and exhausting effects of absorbing oil fume and hot air. Good, smooth internal ventilation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below in conjunction with accompanying drawing:

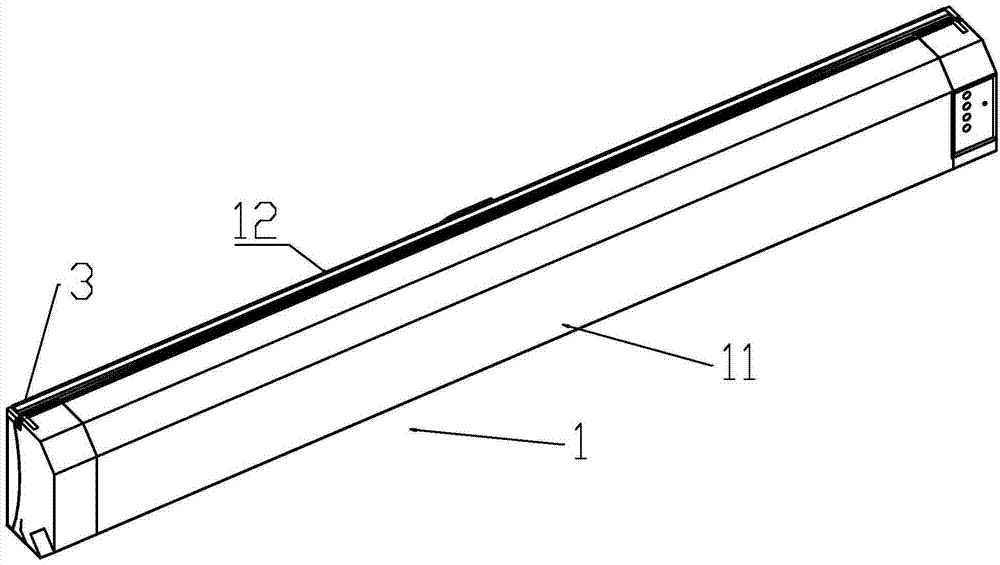

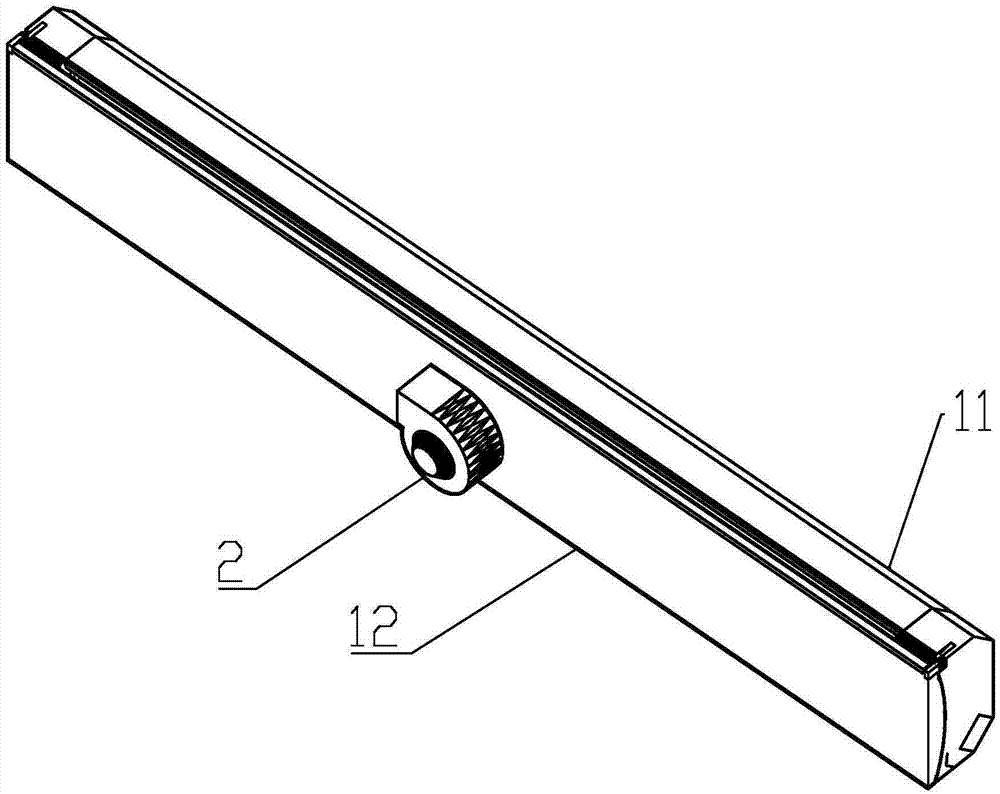

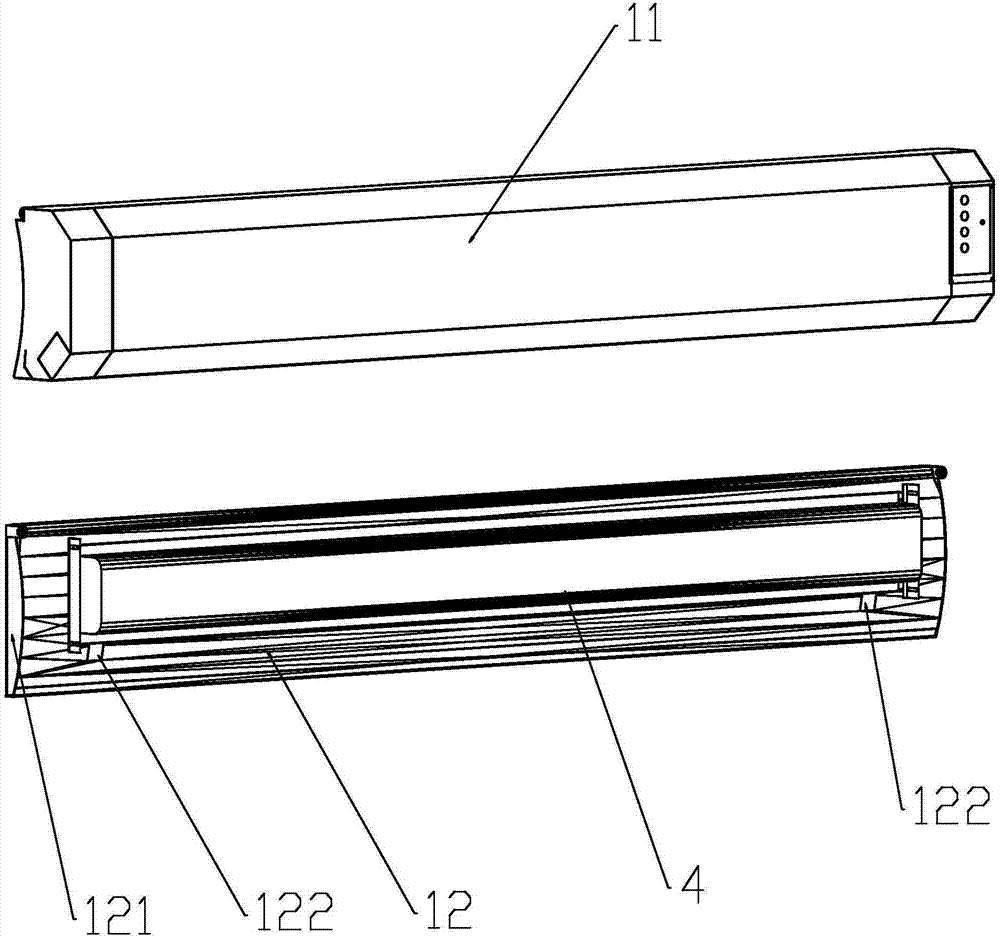

[0027] As shown in the figure, an exhaust device for a printing machine is applied to the subsequent drying step of the printing machine, and includes a cover body 1 covering the drying part 4 of the printing machine. There is a gap for printing sheets such as paper or cloth to pass through. The printing sheets enter from the upper end and pass through the lower end after being dried by the drying part. The exhaust fan 2 for extracting oil fume is connected to the cover body 1 . The exhaust fan 2 is arranged at the rear of the cover body 1 . The exhaust fan 2 discharges the heat and ink to the outside through the pipeline, so as to prevent the indoor high temperature and ink gas from harming the body and endangering health.

[0028] The cover body 1 includes a front cover 11 and a rear cover 12 , the upper parts of the front cover 11 and the rear cover 12 are connected by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com