Low-nitrogen condensation wall-mounted furnace and application method thereof

A condensing wall and water-cooling technology, applied in lighting and heating equipment, fluid heaters, etc., can solve problems such as corrosion of the main heat exchanger, excessive CO gas, and small combustion load adjustment ratio, and achieve uniform airflow, superior performance, and avoid The effect of hot water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

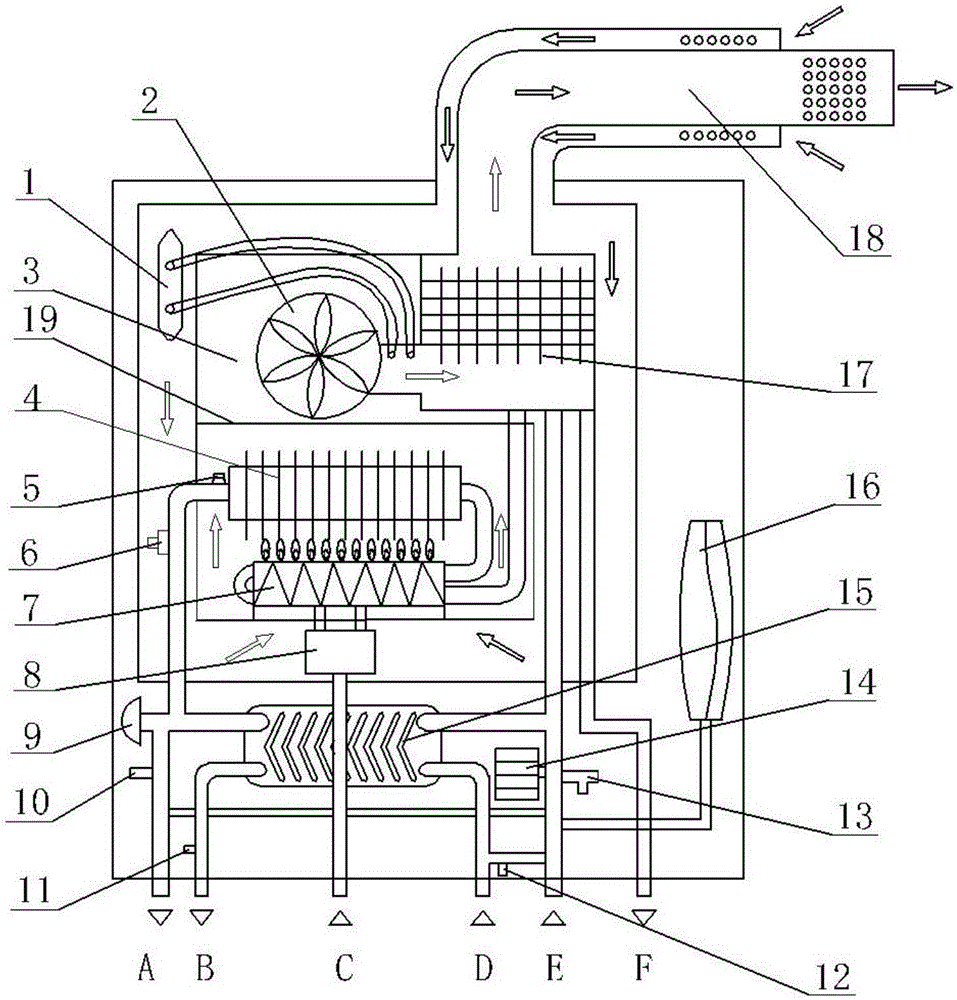

[0037] from figure 1 It can be seen that the low-nitrogen condensing wall-hung boiler disclosed in the present invention includes a wind pressure switch 1, a fan 2, a smoke collecting hood 3, a main heat exchanger 4, a mechanical temperature controller 5, a heating temperature probe 6, and a water-cooled burner. 7. Gas valve 8, three-way valve 9, water pressure sensor 10, hot water temperature probe 11, water supply valve 12, safety pressure relief valve 13, circulating water pump 14, plate heat exchanger 15, expansion tank 16, condensing heat exchanger 17. Coaxial smoke supply and exhaust pipe 18, ventilation baffle 19. Heating water outlet A, domestic hot water outlet B, gas inlet C, domestic cold water inlet D, heating return water outlet E, condensate water outlet F.

[0038] combine Figure 5 with Image 6 It can be seen that the gas valve 8 is composed of a main on-off valve 81 , a proportional regulating valve 82 and two on-off valves 83 .

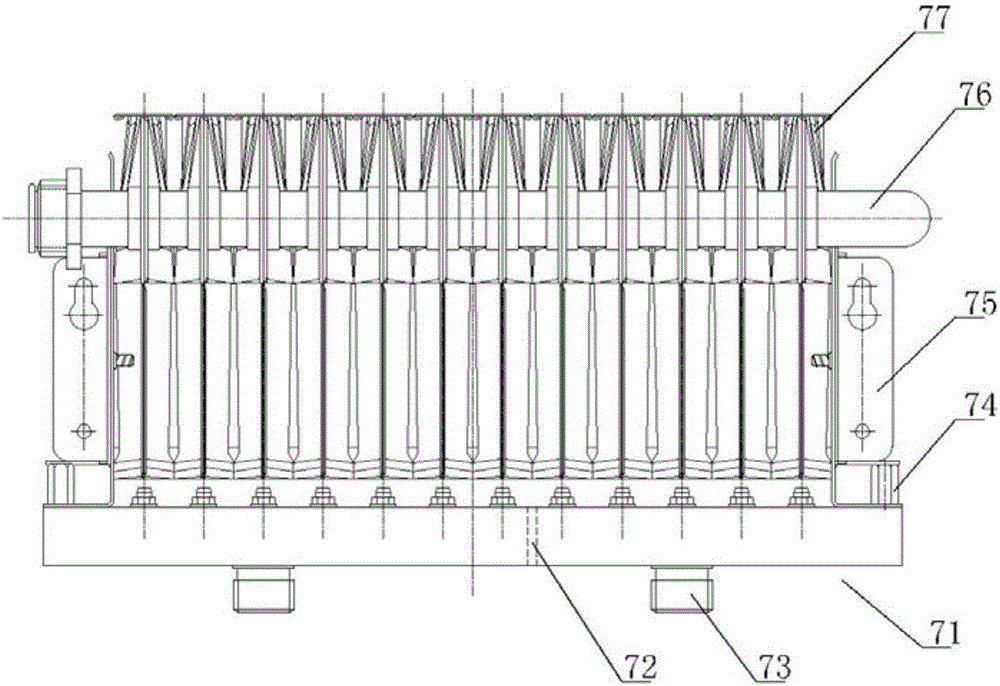

[0039] from figure 2It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com