Patents

Literature

87results about How to "Avoid Excessive Emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

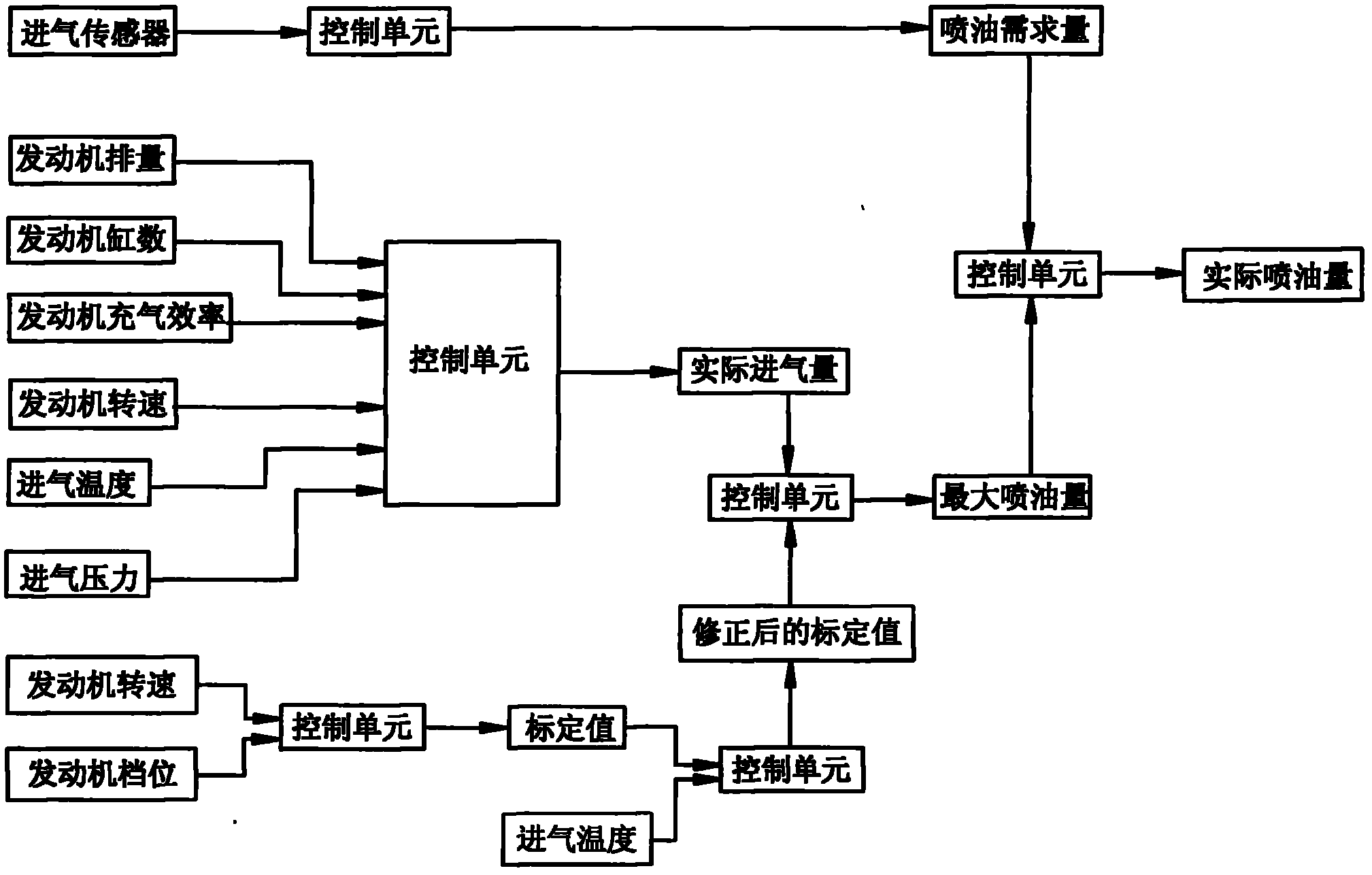

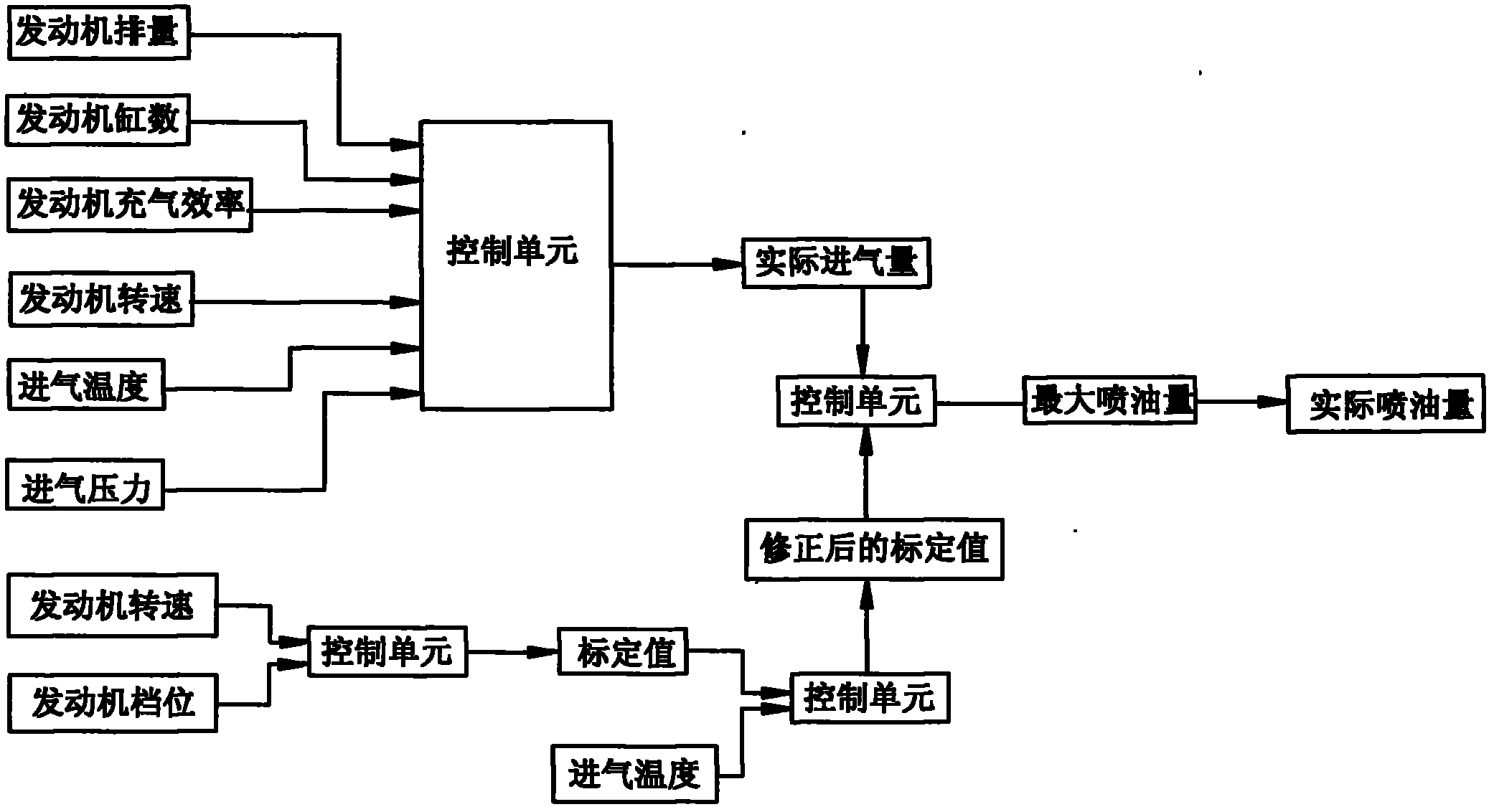

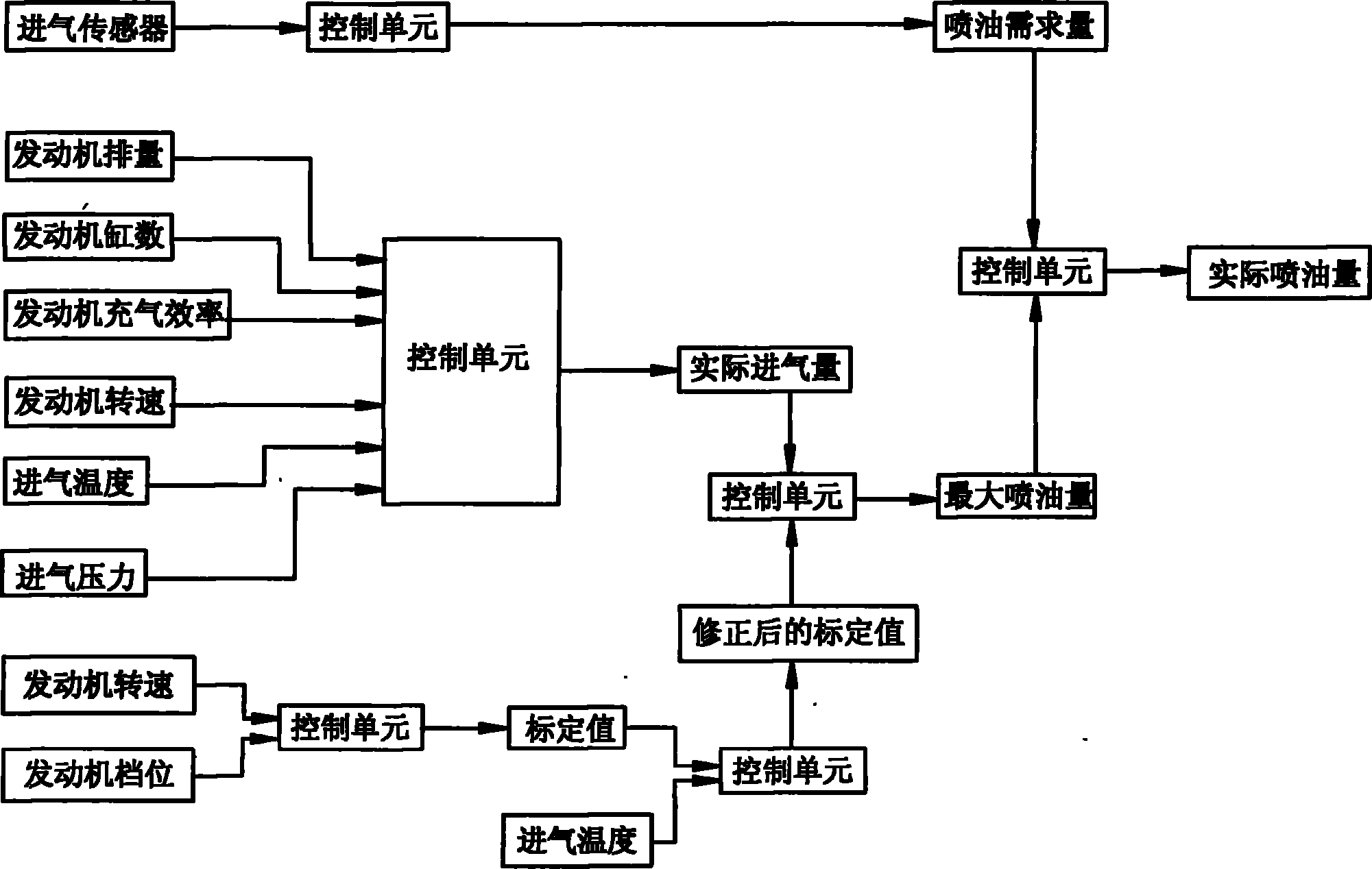

Method for controlling oil injection of diesel engine

ActiveCN101988440AAvoid Excessive Exhaust EmissionsLow costElectrical controlMachines/enginesEngine displacementExhaust gas

The invention discloses a method for controlling the oil injection of a diesel engine, which is used for reducing tail-gas pollution. The method comprises the following steps: calculating a demanded injected oil amount by a control unit according to an air inflow measured by an air inlet sensor, calculating actual air inflow according to the engine displacement, the cylinder number of the engine,the volumetric efficiency of engine, the information of engine speed and the actual intake pressure which is measured by a boost pressure sensor in a pressurization system, obtaining calibration values by looking up a gauge according to the engine speed information and the engine gear information, and finally obtaining a maximum injected oil amount according to the actual air inflow and the calibration values, wherein the calibration values refer to a specific value of air inflow and injected oil amount of maximum torque (obtained through a pretest) of the engine under the condition that the engine is at a special gear and a special speed, and the tail gas is up to the standard; when the demanded injected oil amount is greater than the maximum injected oil amount, the control unit controls the actual injected oil amount according to the maximum injected oil amount, and when the demanded injected oil amount is less than or equal to the maximum injected oil amount, the control unit controls the actual injected oil amount according to the demanded injected oil amount.

Owner:CHERY AUTOMOBILE CO LTD

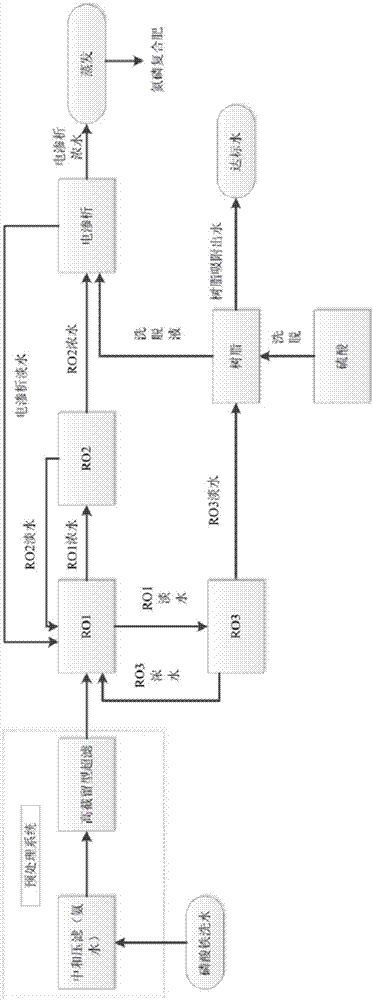

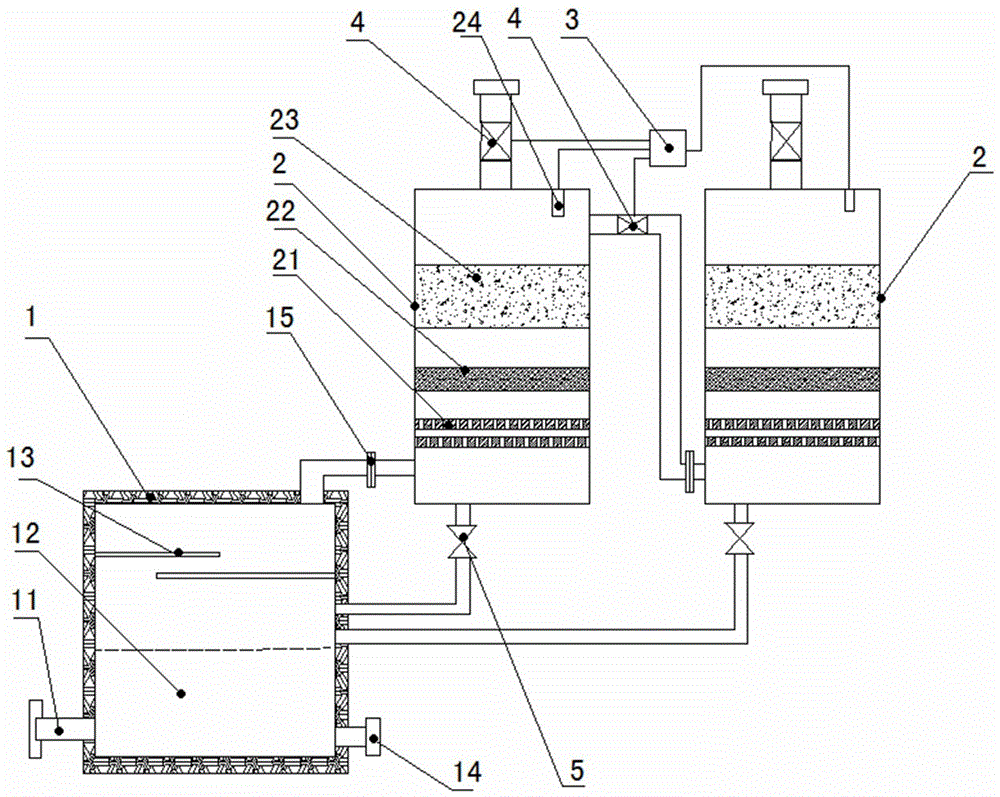

Ferric phosphate wastewater treatment process and treatment device

InactiveCN107082522ARealize resource processingIncreased efficiency of subsequent evaporationGeneral water supply conservationWater contaminantsPhosphatePhosphoric acid

The invention discloses a ferric phosphate wastewater treatment process and treatment device, wherein the treatment process comprises the following steps of (1) membrane concentration: ferric phosphate wastewater is subjected to membrane concentration to obtain concentrated water and fresh water, wherein the membrane concentration includes reverse osmosis and / or electroosmosis; (2) evaporation: the concentrated water is evaporated to recycle a nitrogen and phosphorus compound fertilizer; the evaporated concentrated liquid flow backs to the membrane concentration front end for circulation treatment; (3) resin treatment: the fresh water and evaporated condensed liquid are subjected to resin absorption treatment; resin absorption effluent is discharged in a standard reaching way or is reused for production; resin analytical liquid is subjected to membrane concentration treatment. Multistage reverse osmosis and resin absorption treatment are combined; ferric polyphosphate wastewater is subjected to desalination and ammonia and nitrogen removal step by step, so that the insulation capability of the whole treatment process on ammonia and nitrogen is higher; the ammonia and nitrogen discharging standard exceeding of effluent can be effectively avoided.

Owner:绍兴齐英膜科技有限公司

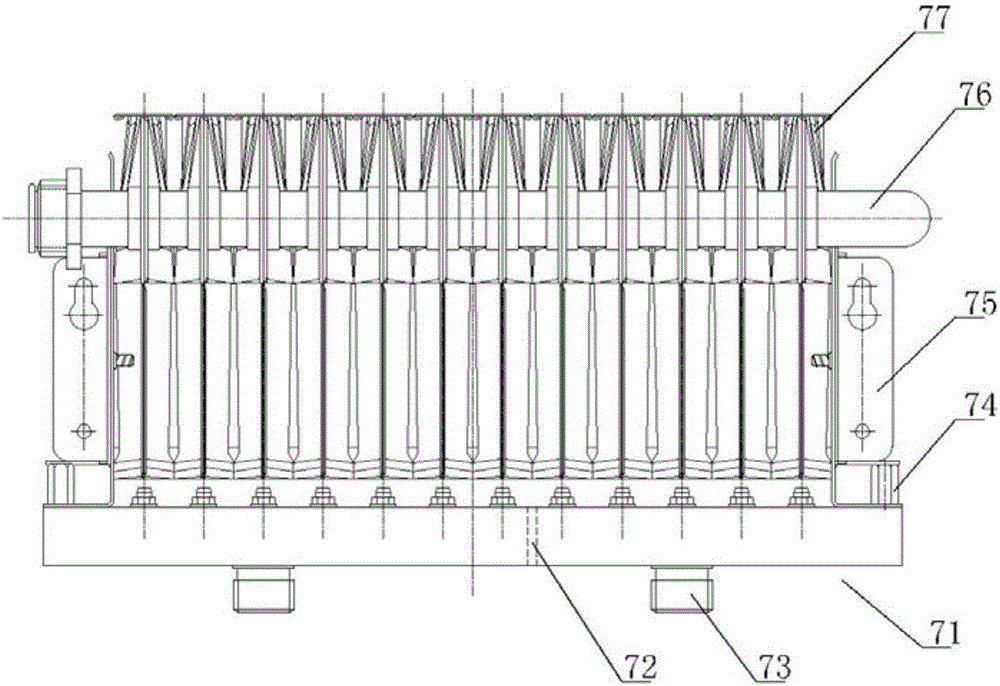

Low-nitrogen condensation wall-mounted furnace and application method thereof

The invention discloses a low-nitrogen condensation wall-mounted furnace and an application method thereof. The low-nitrogen condensation wall-mounted furnace comprises a draught fan, a fume collecting hood, a gas valve and a water-cooling combustor. An inner cavity of a gas distributing pipe of the water-cooling combustor is divided into two independent sections through a block plate, and each section is connected with a gas inlet joint. The gas valve is composed of a main on-off valve, a proportion regulating valve and two on-off valves, the main on-off valve is connected with a main gas inlet pipe, and outlets of the two on-off valves communicate with the two sections of the gas distributing pipe separately. The gas distributing pipe is sectioned, all fire rows or a part of fire rows on the gas distributing pipe are controlled to combust, small duty ratio is reduced, and the problems of flameout and too hot water temperature in summer can be solved. In addition, the constant-speed draught fan is adopted for the wall-mounted furnace, so the problem of corrosion of condensate water to a main heat exchanger can be solved. A ventilation baffle is further arranged at the bottom of the fume collecting hood to solve the problem of excessive CO emission under limit gas test conditions. Through experimental verification, when the small load regulation ratio of the wall-mounted furnace is between 0.35-0.5, the problems of flameout and too hot water temperature in summer can be solved.

Owner:MACRO THERMAL ENERGY TECH

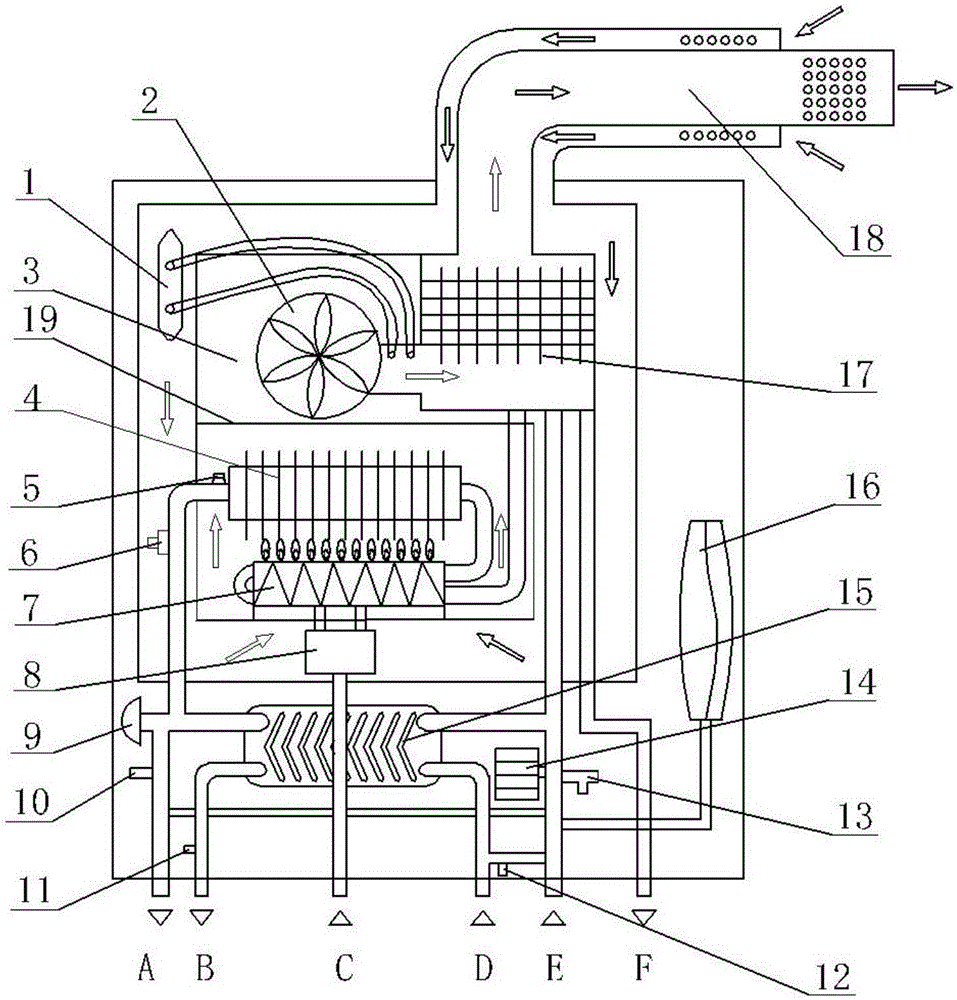

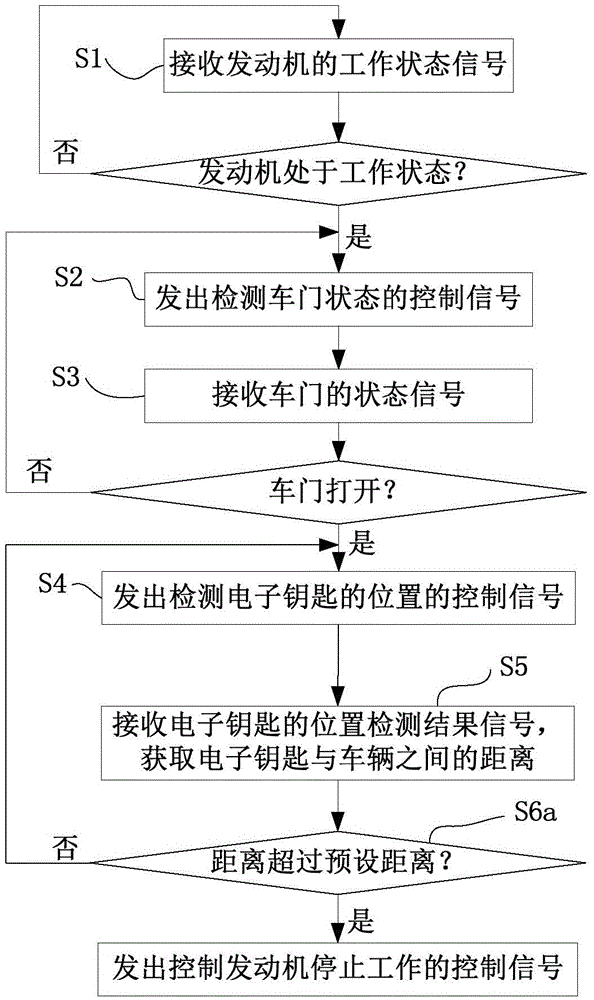

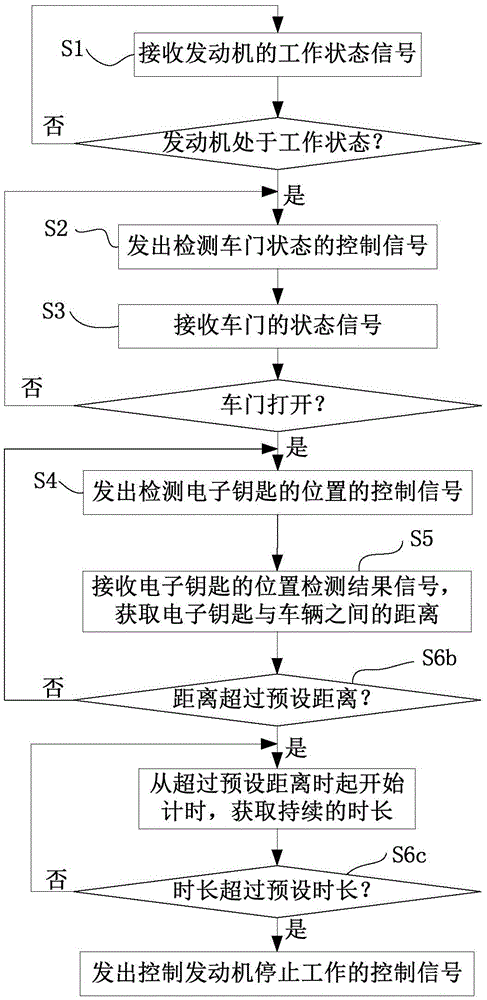

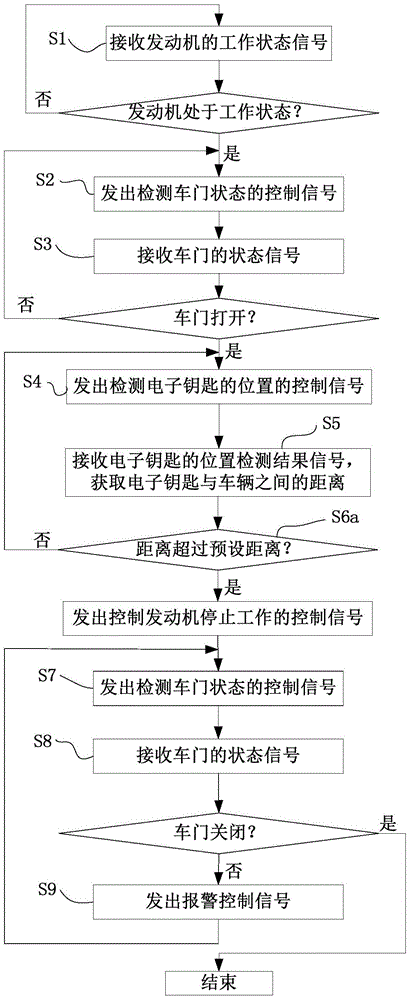

Vehicle control method, device and system and vehicle

InactiveCN106740566APrevent theftAvoid lostNon-mechanical controlsEngine controllersStopped workToxic gas

The invention provides a vehicle control method, device and system and a vehicle. According to the vehicle control method and device, firstly, a working state signal of an engine is firstly received, and whether the engine is in a working state or not is judged; if the engine is in the working state, a control signal for detecting the state of a vehicle door is transmitted; a state signal of the vehicle door is received, and whether the vehicle door is opened or not is judged; if the vehicle door is opened, a control signal for detecting the position of an electronic key is transmitted; a position detection result signal of the electronic key is received, and the distance between the electronic key and the vehicle is obtained; when the distance between the electronic key and the vehicle exceeds a preset distance, a control signal for controlling the engine to stop working is transmitted. Even when a driver forgets to shut down the vehicle when leaving the vehicle, the engine can automatically stop working after the driver is away from the vehicle, the threat of toxic gas such as carbon monoxide generated by running of the engine to health is avoided, and potential safety hazards are eliminated.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

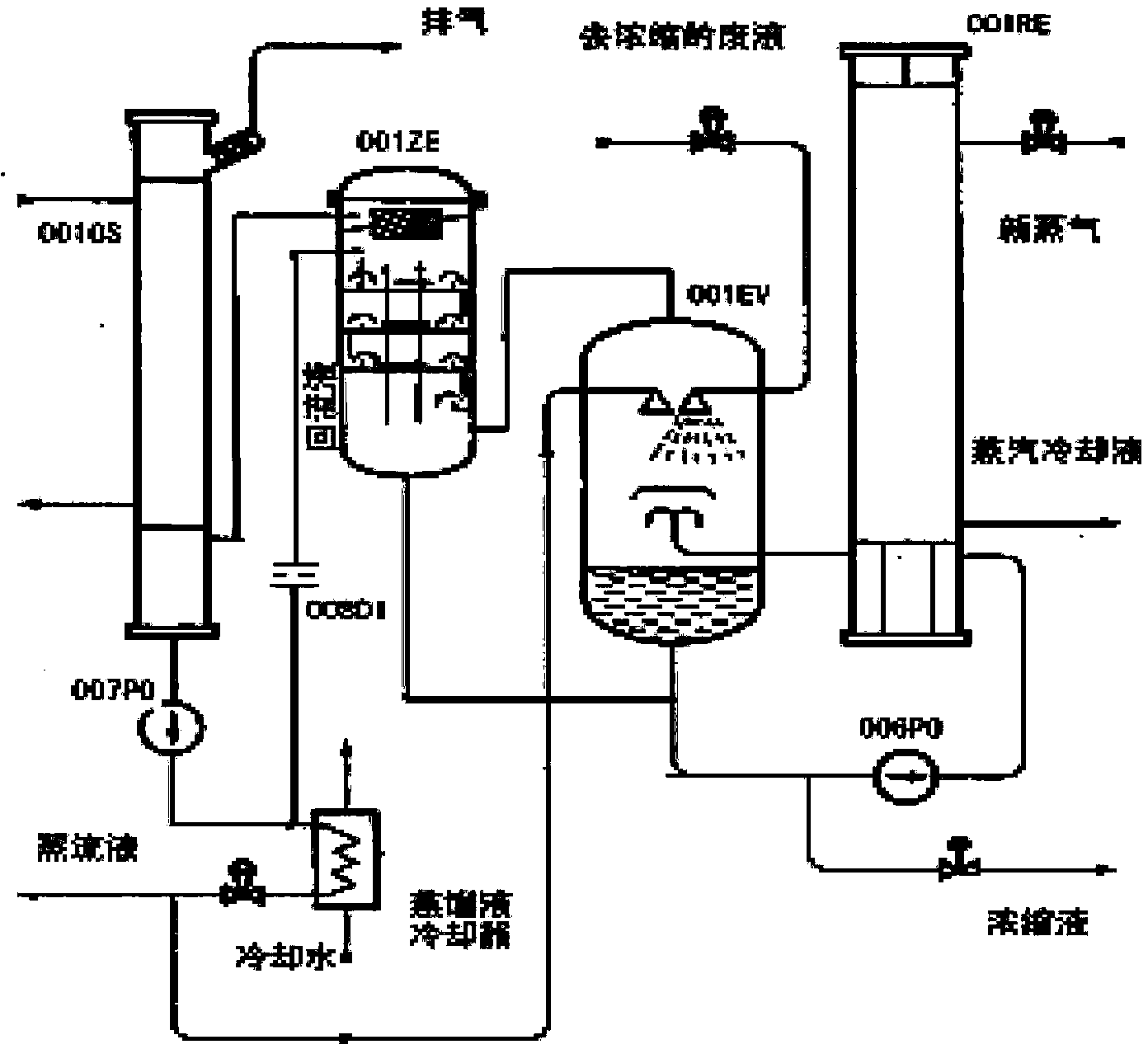

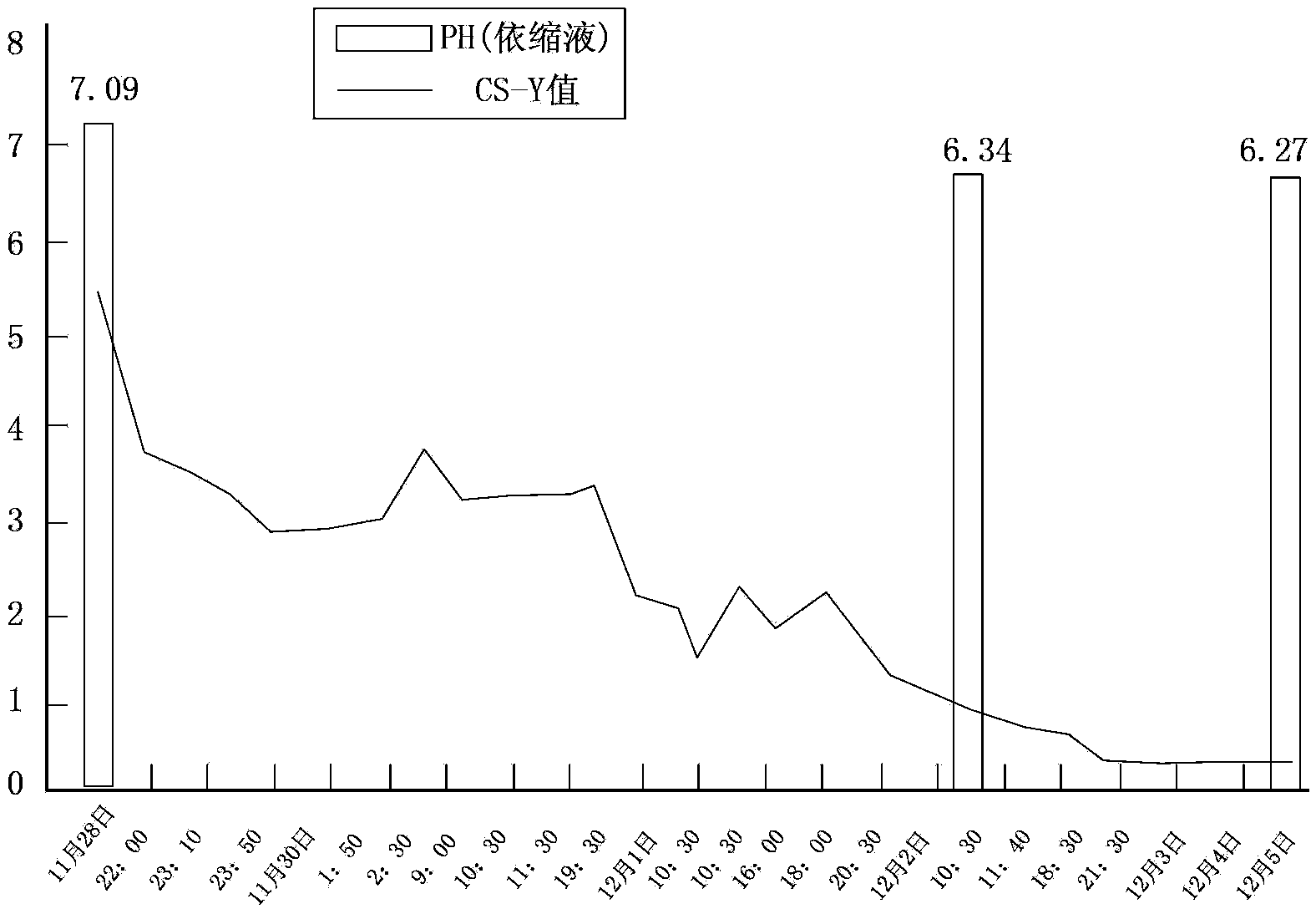

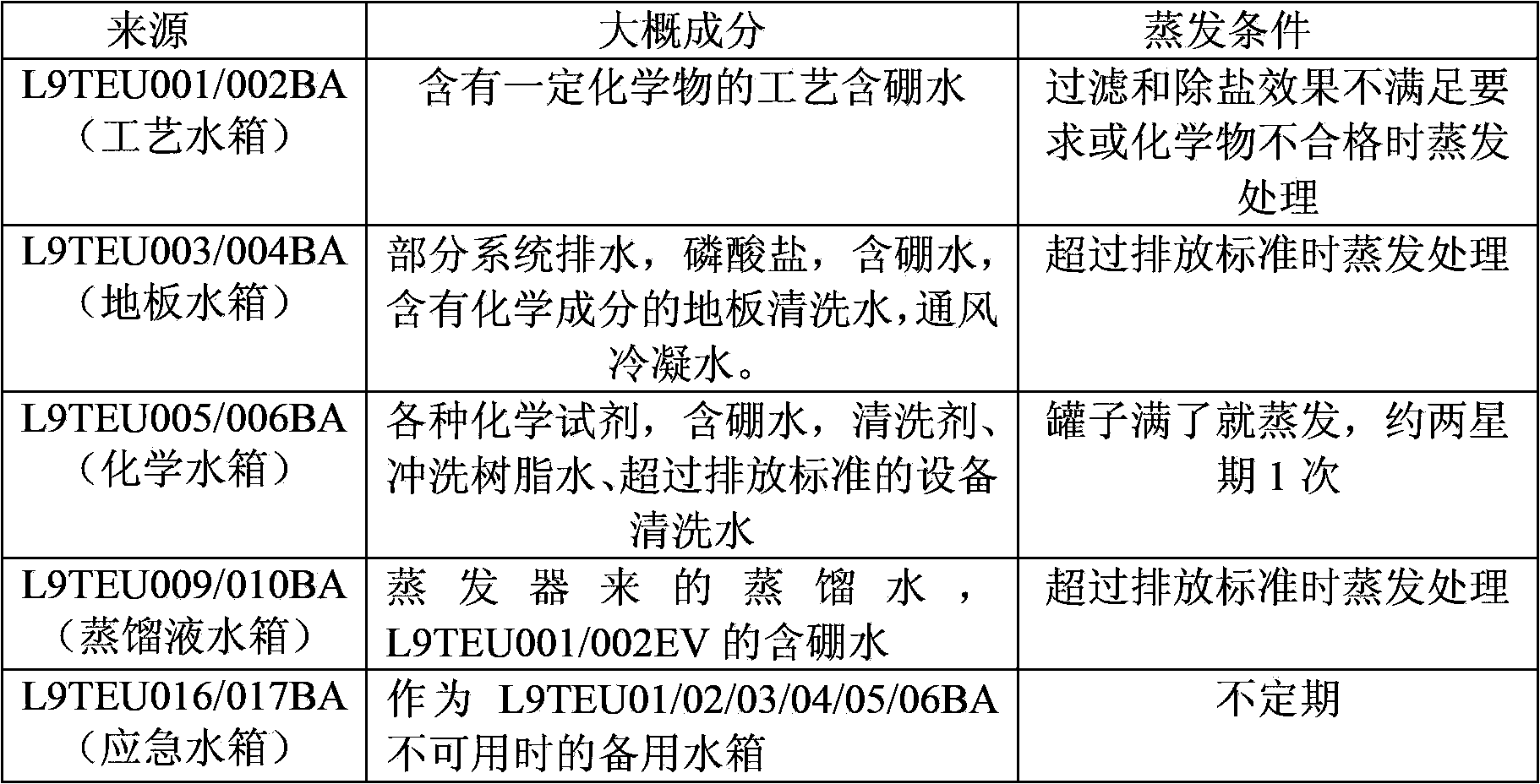

Evaporation treatment method for radioactive waste liquids of nuclear power plant

ActiveCN103794260AImprove efficiencyEasy to handleRadioactive decontaminationLiquid wasteNuclear power

The invention discloses an evaporation treatment method for radioactive waste liquids of a nuclear power plant. The method includes the following steps: firstly, collecting and gathering various waste liquids; secondly, subjecting the waste liquids to evaporation treatment to form distillate and concentrate, and detecting radioactivity of the distillate and the concentrate; thirdly, when radioactivity detection results are lower than radioactive discharge standards, discharging the distillate, when boron concentration in the concentrate is detected to be up to solidification standards, discharging and solidifying the concentrate, and finishing evaporation; if the radioactivity detection results are equal or higher than the radioactive discharge standards and the boron concentration in the concentrate is detected to be less than 10000ppm, adding acid to stepwise regulate pH value of the concentrate to be below 7, and repeating the second and third steps till evaporation is finished. The method is simple in process, convenient to operate, and capable of greatly lowering radioactivity of the distillate to enable the radioactivity to be lower than the discharge standards.

Owner:CHINA GENERAL NUCLEAR POWER CORP +1

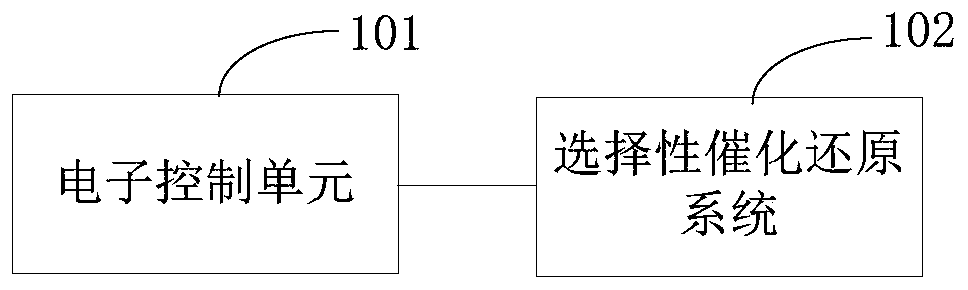

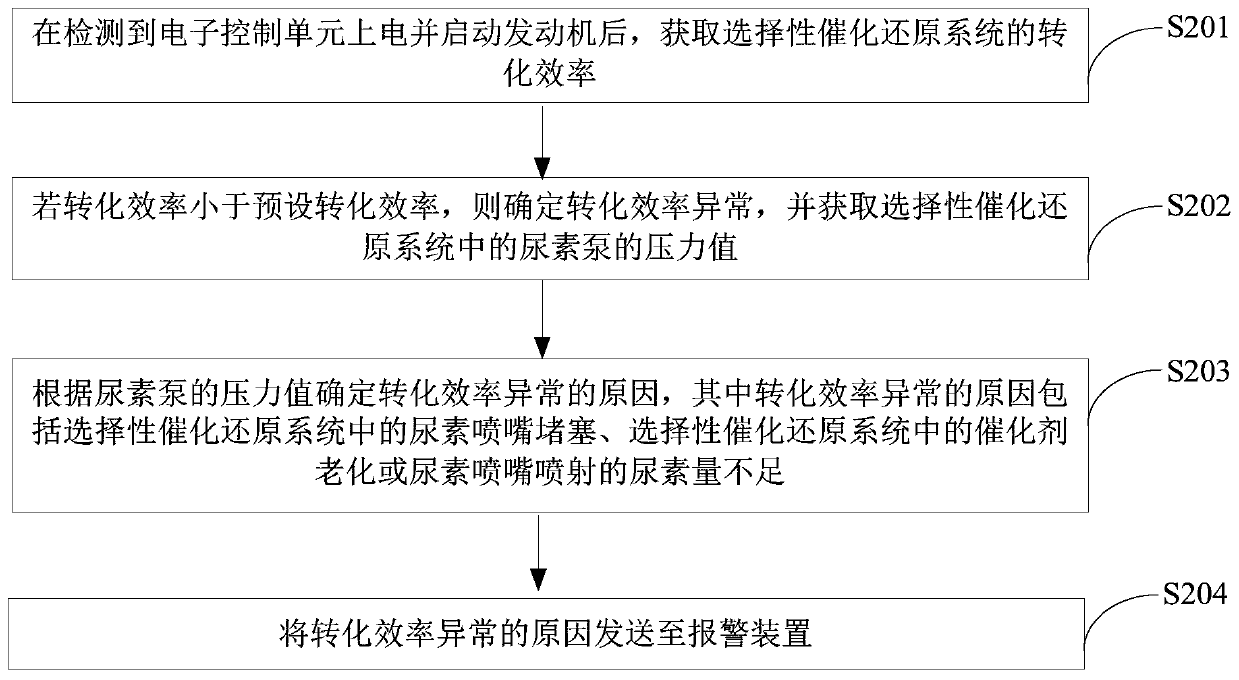

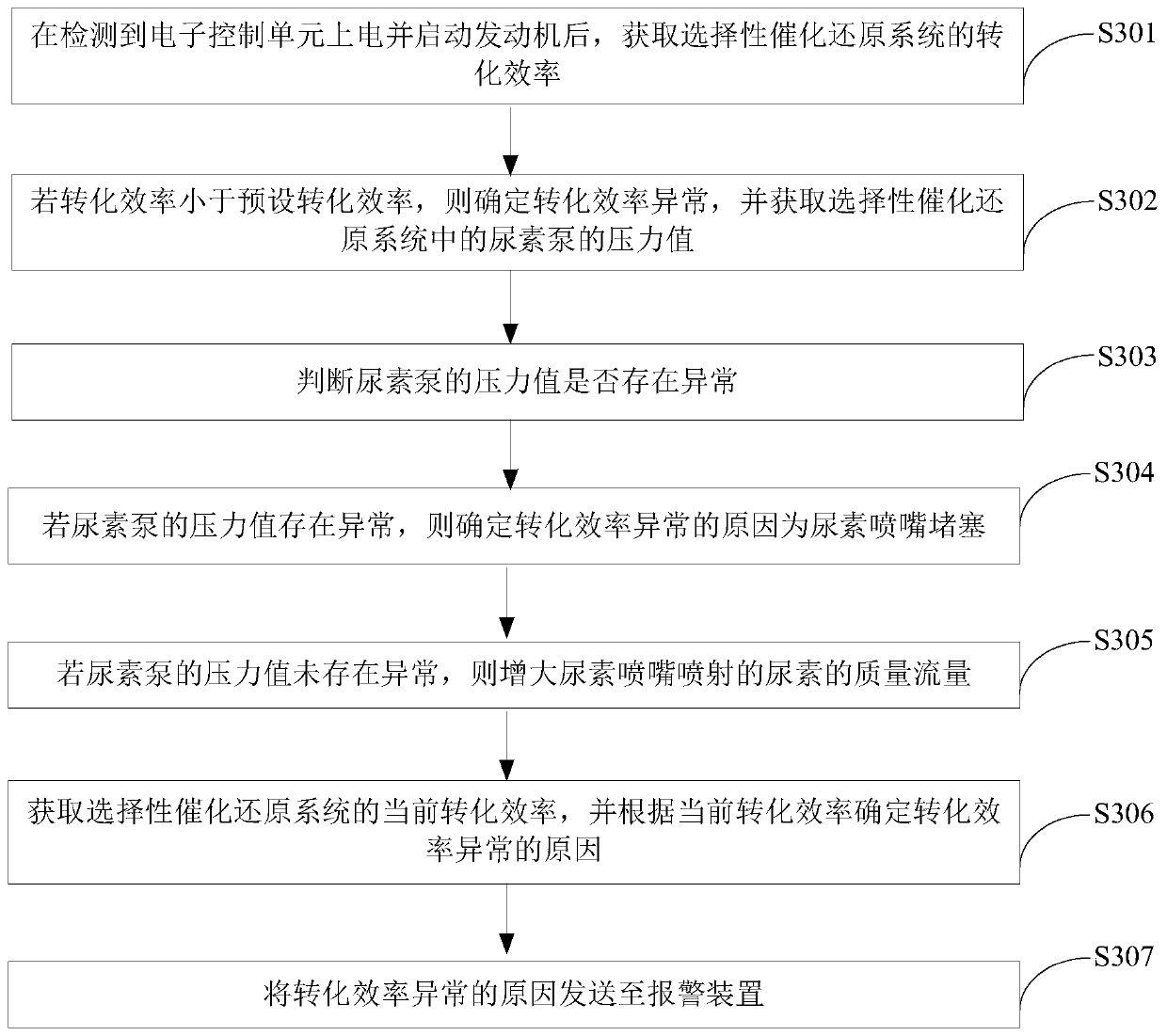

Abnormity positioning method and device and electronic control unit

ActiveCN110541745AAvoid Excessive EmissionsExacerbate pollutionInternal combustion piston enginesExhaust apparatusElectricityEngineering

The embodiment of the invention provides an abnormity positioning method and device and an electronic control unit. The method comprises the following steps that conversion efficiency of a selective catalytic reduction system is acquired after detecting that the electronic control unit is electrified and starts an engine; if the conversion efficiency is less than preset conversion efficiency, theconversion efficiency is determined to be abnormal, and a pressure value of a urea pump in the selective catalytic reduction system is acquired; reasons that the conversion efficiency is abnormal aredetermined according to the pressure value of the urea pump, wherein the reasons that the conversion efficiency is abnormal comprise the blockage of a urea nozzle in the selective catalytic reductionsystem, the aging of a catalyst in the selective catalytic reduction system or the insufficient amount of urea sprayed through the urea nozzle; and the reasons that the conversion efficiency is abnormal are sent to an alarm device. According to the method, the accuracy of positioning the reasons of the abnormal conversion efficiency can be improved, and after the reasons that the conversion efficiency is abnormal are accurately positioned, the reasons are sent to the alarm device, so that the related personnel can directly solve the problem that the conversion efficiency is abnormal successfully according to the reasons.

Owner:WEICHAI POWER CO LTD

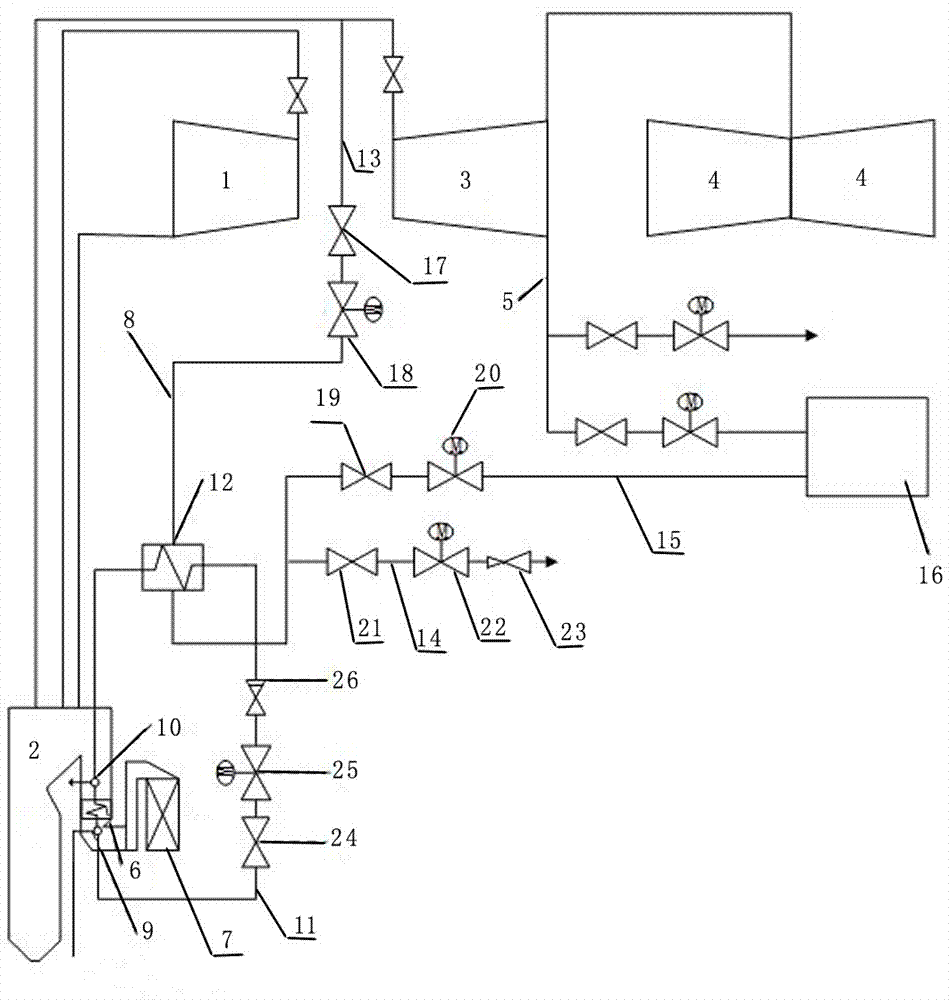

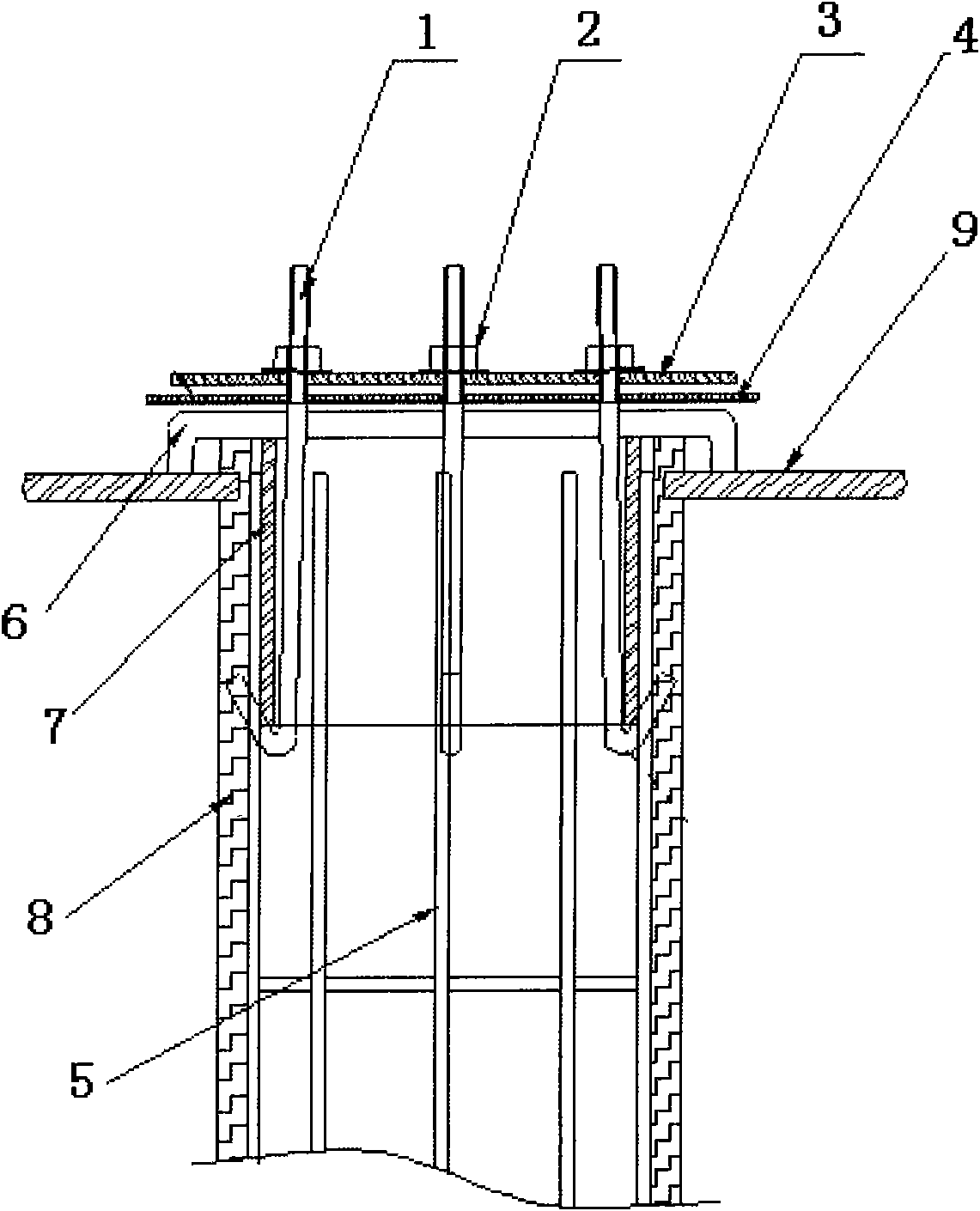

Peak-load-regulating heat supply system of thermoelectric unit

InactiveCN107270383ASolve the problem of not being able to meet the demand of industrial steamIncrease steam intakeLighting and heating apparatusSteam useLow loadProcess engineering

The invention discloses a peak-load-regulating heat supply system of a thermoelectric unit. The peak-load-regulating heat supply system comprises a turbine high-pressure cylinder, a boiler, a cold reheated steam pipeline, a steam turbine middle-pressure cylinder and a reheated steam pipeline, wherein a coal economizer is arranged on the boiler; the coal economizer is connected with an SCR denitrification system; a steam outlet of the boiler is further connected with a reheated steam heat-supply branch; and a bypass water-feeding pipeline is arranged between an inlet header of the coal economizer and an outlet header of the coal economizer. The peak-load-regulating heat supply system disclosed by the invention solves the problems that industrial steam consumption parameter requirements cannot be met under a low-load working condition and steam inlet amount of a steam turbine low-pressure cylinder is small by utilizing a high-parameter heat supply steam source, reduces heat release amount of smoke gas in the coal economizer, guarantees that SCR equipment does not exit operation, guarantees that the thermoelectric unit can operate under relatively low load, and improves peak-regulating capacity of the thermoelectric unit.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Online broken bag blocking device for pulse jet bag type dust collector

InactiveCN101844017AQuick plugGuaranteed to workDispersed particle filtrationProduction lineEngineering

The invention discloses an online broken bag blocking device for a pulse jet bag type dust collector. The device comprises a closing plate, a spacer and a screw rod. The closing plate and the spacer are superposed on each other and are provided with corresponding installing holes; the lower end of the screw rod is provided with a hook; the top end of the screw rod is inserted into the installing hole from the lower side of the spacer and extends out of the closing plate; and a nut is screwed at the extension end of the screw rod. A broken bag of the dust collector is rapidly blocked by using the closing plate, so online maintenance time of equipment is shortened; the equipment can run normally as soon as possible; and the accident risk of online maintenance of the dust collector is reduced. Simultaneously, the device reduces possibilities of causing fluctuation on a working condition of a dust-collecting system, affecting the running of an entire production line and causing an equipment failure due to a large amount of intake air into the dust collector after a top door is opened in an online maintenance process of the dust collector, and provides an emergency measure for the situation that no new filter bag is available for replacement on field when the bag of the dust collector is broken.

Owner:HEFEI CEMENT RES DESIGN INST

Fixed spray flue gas purifying device

InactiveCN102688684AImprove adsorption efficiencySimple structureDispersed particle filtrationEngineeringCorrosion

The invention relates to a fixed spray flue gas purifying device, particularly to a device for purifying flue gas generated by a domestic waste combustion furnace, and belongs to the technical field of environmental protection equipment. The fixed spray flue gas purifying device mainly comprises a water tank, a deacidification raw material tank, a semi-dry reaction tower, a fixed spray gun, a first fly ash conveyor, an ash storage bunker, an intermediate flue duct, an active carbon storage bunker, a first conveying blower, a Ca (OH)2 dry powder storage bunker, a second convey blower, a second fly ash conveyor, a bag type dust remover, an induced draft fan, a chimney, a tail end flue duct, a third pipeline, a fourth pipeline and an active carbon measuring and feeding device. The device is simple, compact and reasonable in structure, the size of a spray nozzle of the fix spray gun is small, the mounting and maintenance is convenient, and the cost is lower; the reaction tower not only has high degree of finish but also has higher corrosion resistance and wearing resistance, so that the service life is prolonged; standby deacidification equipment is provided to prevent that emission of acid exceeds the standard; and the adsorption efficiency of Dioxin, heavy metal and other harmful pollutants is improved.

Owner:WUXI HUAXING ELECTRIC POWER ENVIRONMENTAL PROTECTION REPAIRING & MFG

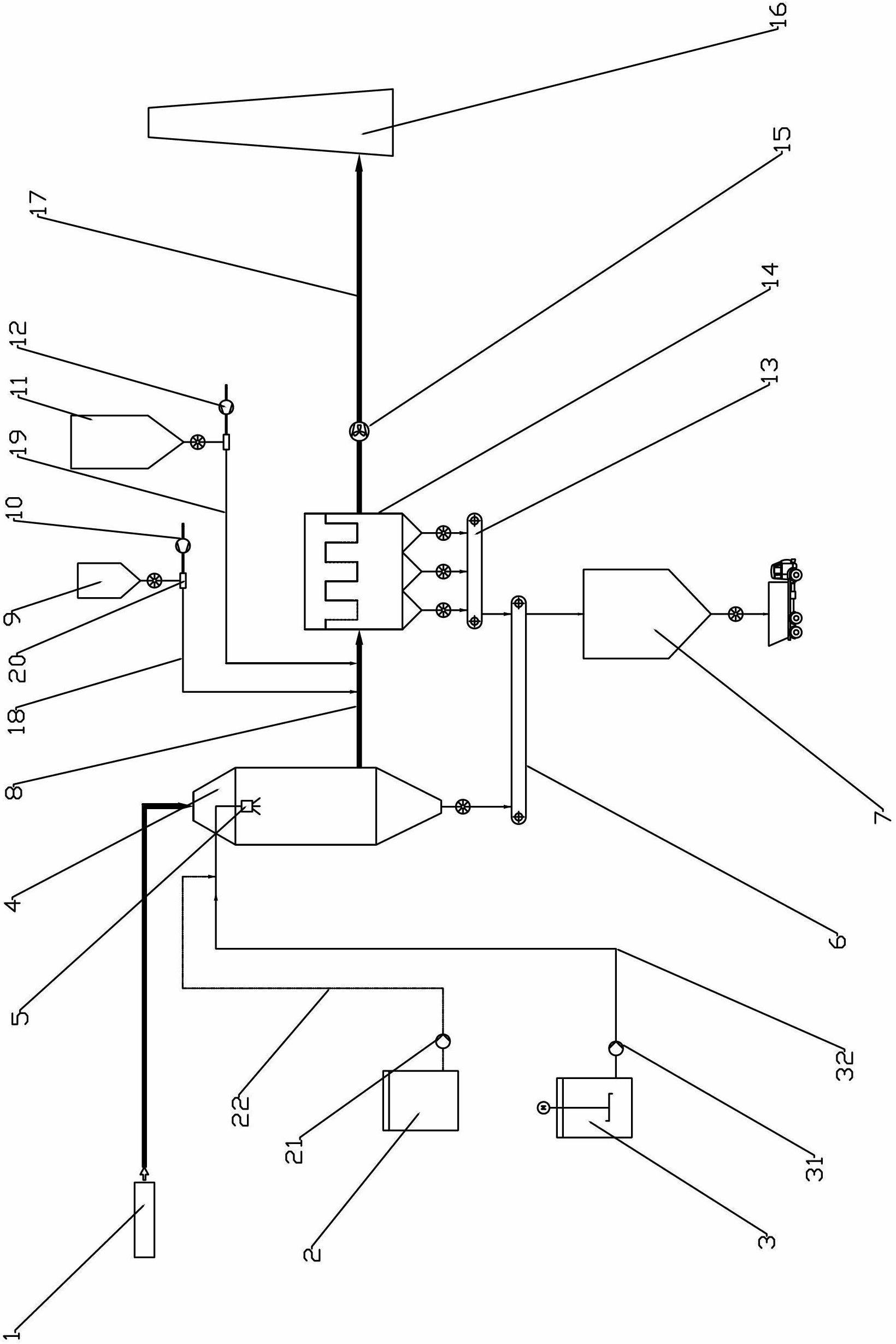

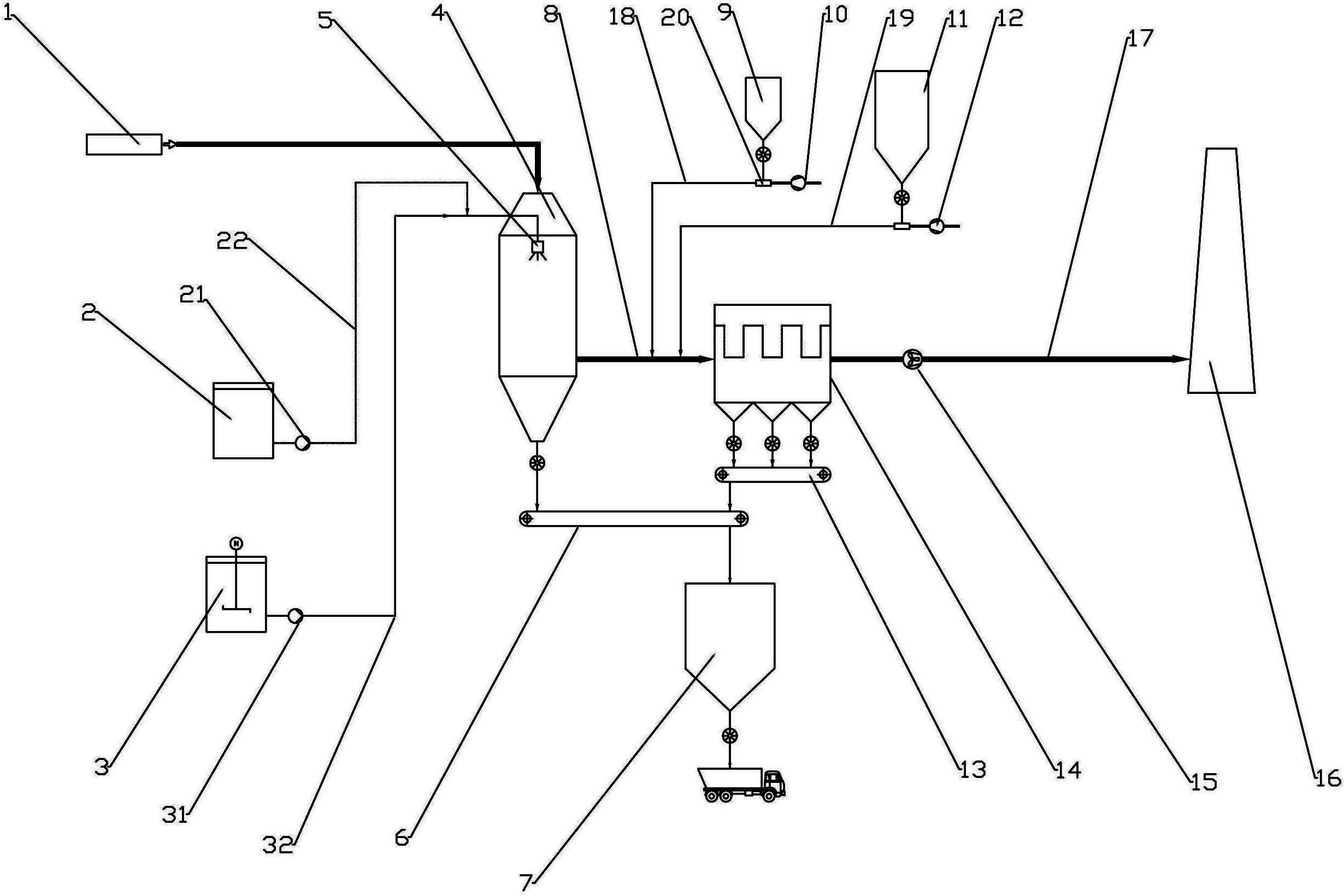

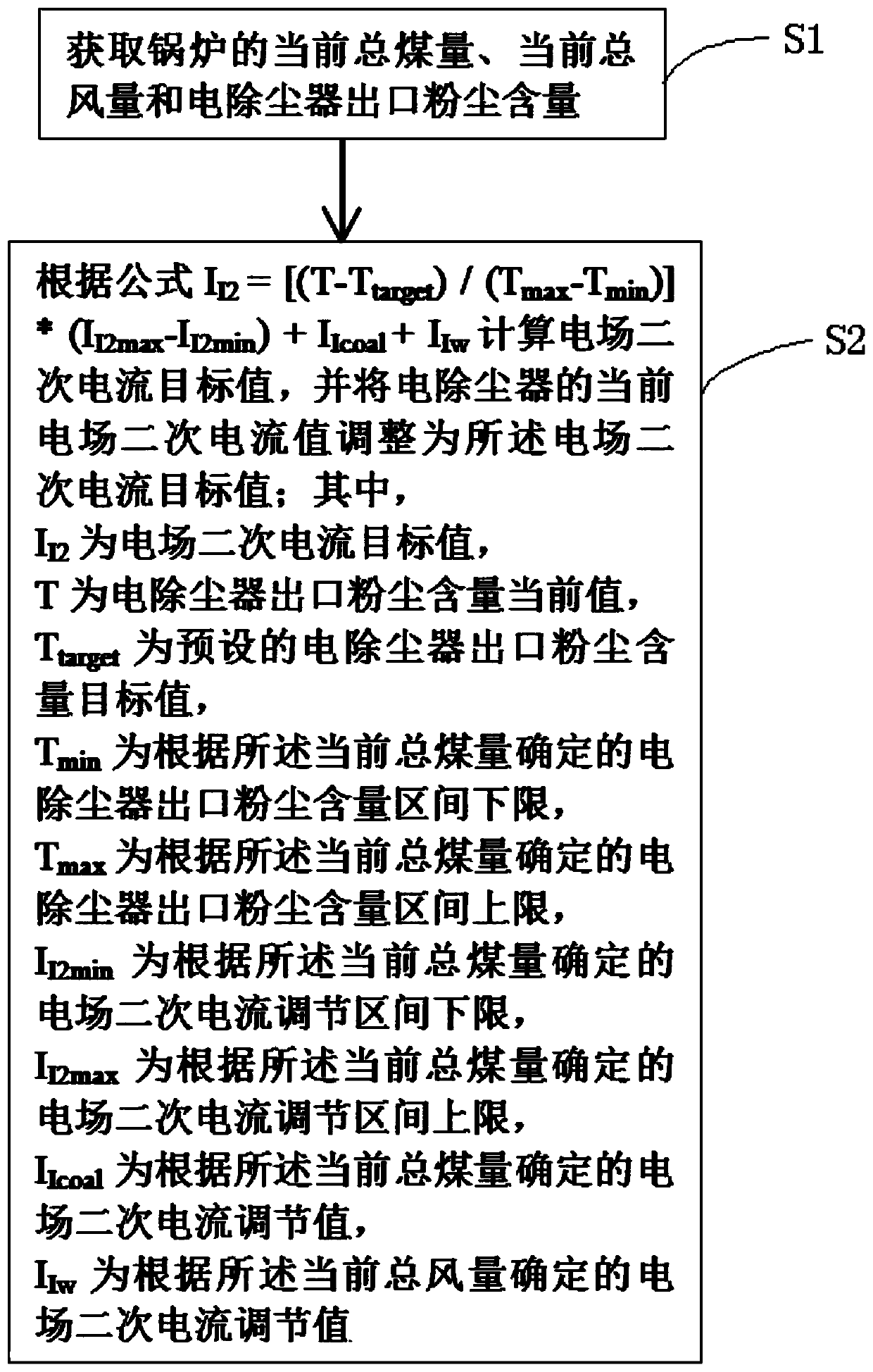

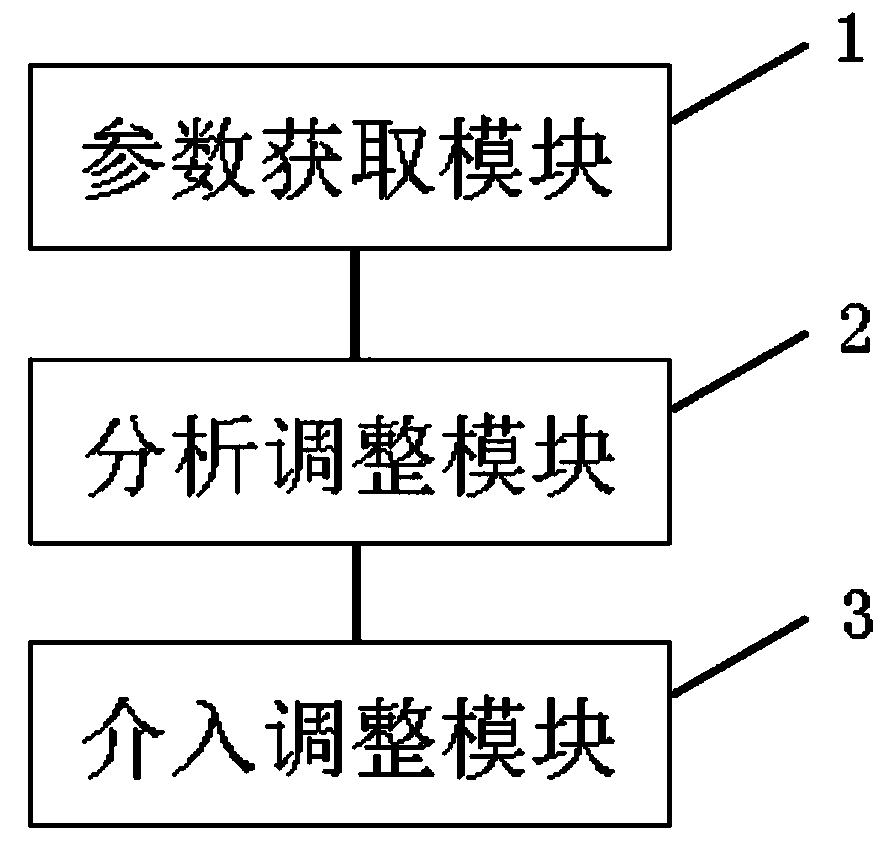

Electric precipitation energy-saving control method and system based on coal quantity and air quantity of boiler

ActiveCN111570093AAccurate measurementOvercoming control biasElectric supply techniquesUnit loadAutomatic control

The invention discloses an electric precipitation energy-saving control method based on the coal quantity and the air quantity of a boiler. The method comprises the steps: obtaining current total coalquantity and current total air quantity of the boiler and electric precipitator outlet dust content; and calculating an electric field secondary current target value according to a formula II2=[(T-Ttarget) / (Tmax-Tmin)]*(II2max-II2min)+IIcoal+IIw, and adjusting the current electric field secondary current value of the electric precipitator to an electric field secondary current target value. Therefore, the total coal quantity of the boiler is used to replace the unit load to control the electric precipitation parameters, the control deviation caused by coal quality change can be overcome, andthe real-time performance is better than that of the unit load; meanwhile, the total air quantity of the boiler serves as a feedforward signal, and a dynamic control effect of dust in the unit load dynamic change process can be improved; and therefore, the automatic control effect of the electric precipitator can be improved, excessive dust emission of a power plant is prevented, the environment-friendly purpose is achieved, the power utilization rate of the power plant is reduced, and the energy-saving purpose is achieved. The invention further discloses an electric precipitation energy-saving control system based on the coal quantity and the air quantity of the boiler, and the beneficial effects are as mentioned above.

Owner:HUANENG PINGLIANG POWER GENERATION CO LTD

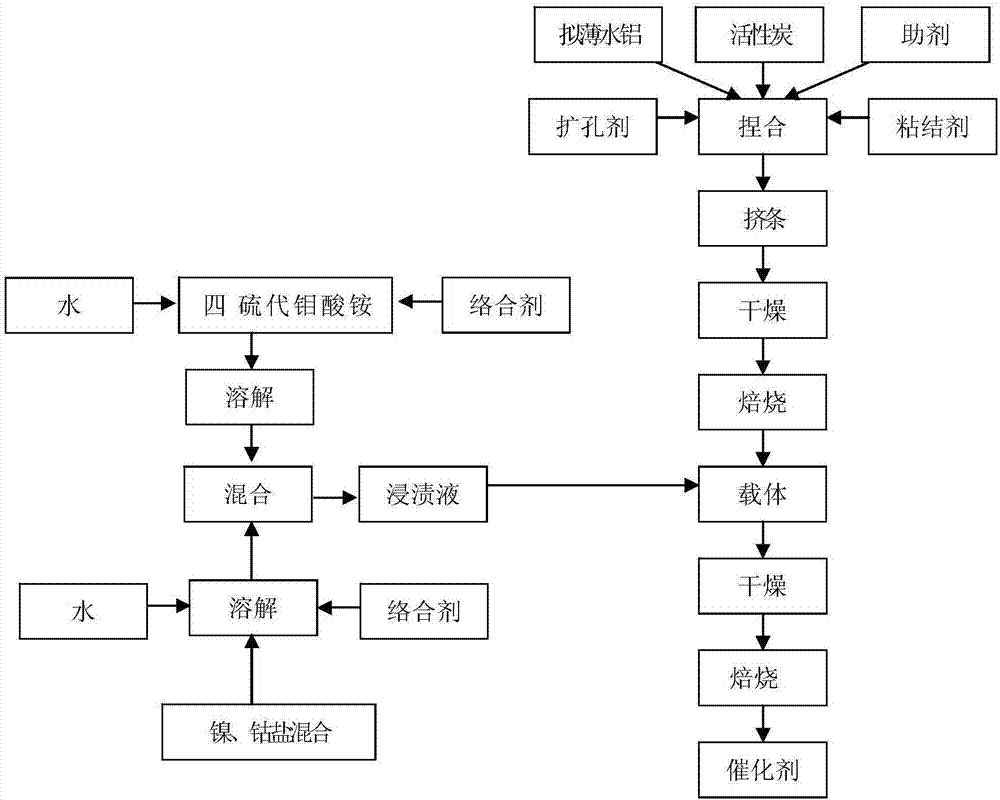

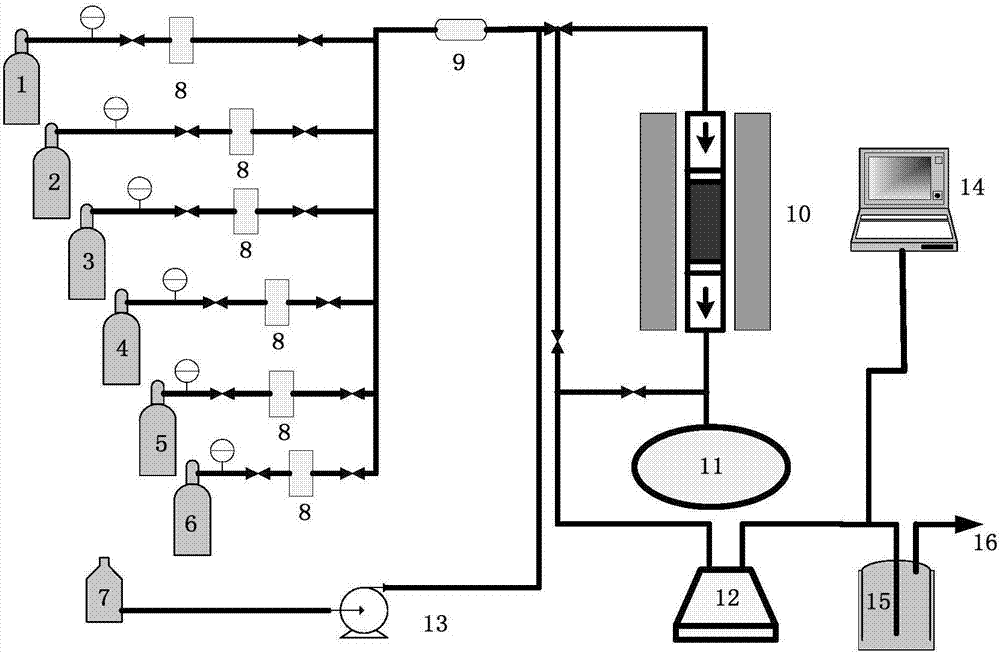

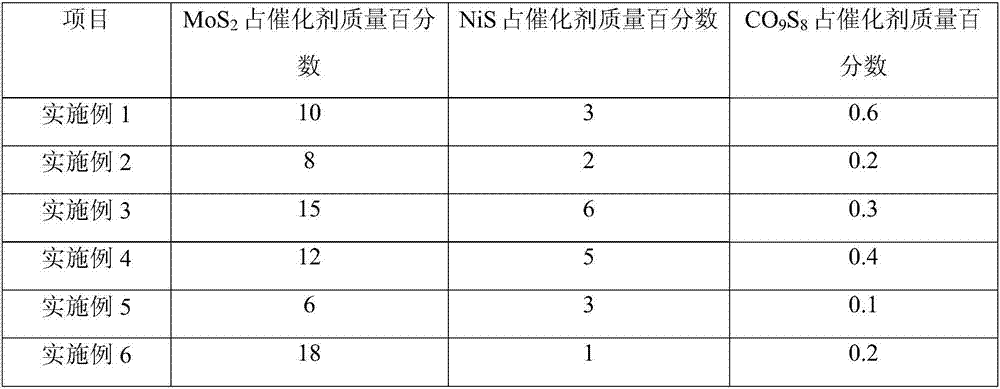

Sulfur tail gas hydrogenation catalyst and preparation method

ActiveCN107469836AHigh initial activityGood stabilityPhysical/chemical process catalystsChemistrySulfide

The invention relates to a novel sulfur tail gas hydrogenation catalyst and a preparation method thereof. Active components in a form of sulfides of the catalyst are supported on a catalyst carrier. The active components are sulfides of cobalt, molybdenum and nickel. The catalyst has the characteristics of no pre-vulcanization, high initial activity and good stability. The catalyst is in a vulcanized state and does not need to be vulcanized in use. Through use of the catalyst, sulfur device problems of environmental protection and safety during pre-vulcanization are avoided, excessive emission of SO2 during sulfur device operation is avoided, green operation is realized and significant economic and social benefits are obtained.

Owner:CHINA PETROLEUM & CHEM CORP

Indoor air purifying device

InactiveCN107126810AImprove purification efficiencyAvoid excessive local loadsGas treatmentDispersed particle filtrationDust detectionEngineering

The invention discloses an indoor air purification device, which comprises a device body; the device body is mainly composed of a first processing chamber, a second processing chamber, a detection chamber and a buffer chamber; a fixing plate is arranged in the first processing chamber, A sliding plate is arranged on the top of the fixed plate, and a sponge layer is arranged between the sliding plate and the fixed plate. A filter plate is arranged on the top of the first processing chamber, and an electric lifting device is fixedly connected to the lower surface of the filter plate. A dust collector is installed in the second processing chamber. Detection sensor, the second processing chamber is provided with a first rotating shaft, the first rotating shaft is fixedly connected with a rotating rod, the top of the second processing chamber is provided with a detection chamber, and a smoke detection sensor is provided in the detection chamber, on the right side of the device body A communicating pipe is fixedly connected to the side wall. The air purifier is conducive to efficiently removing dust in the air and ensuring that the gas is discharged up to the standard. The smoke detection sensor and the smoke detection sensor avoid excessive gas discharge and are easy to move.

Owner:张大化

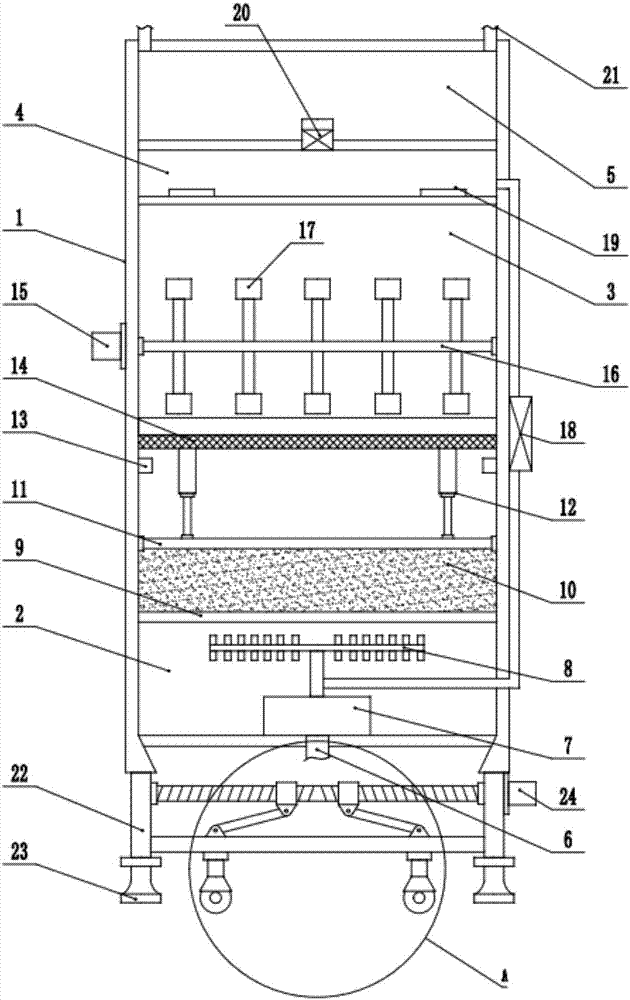

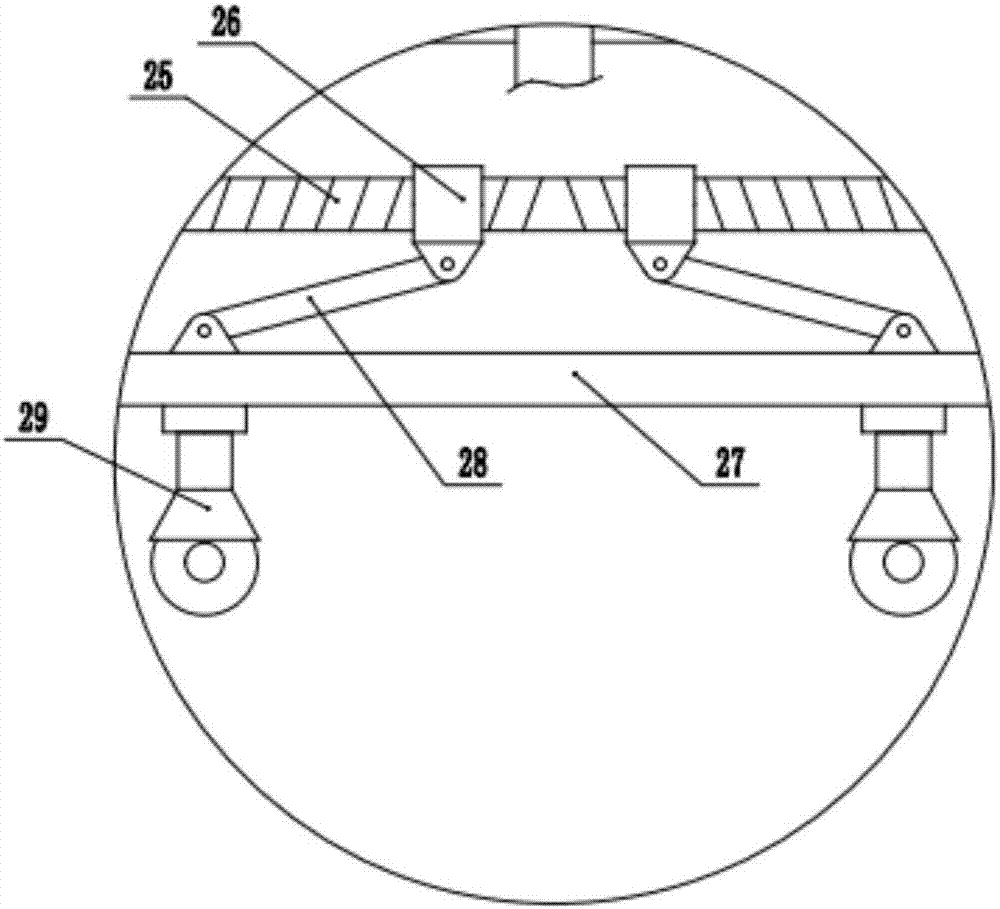

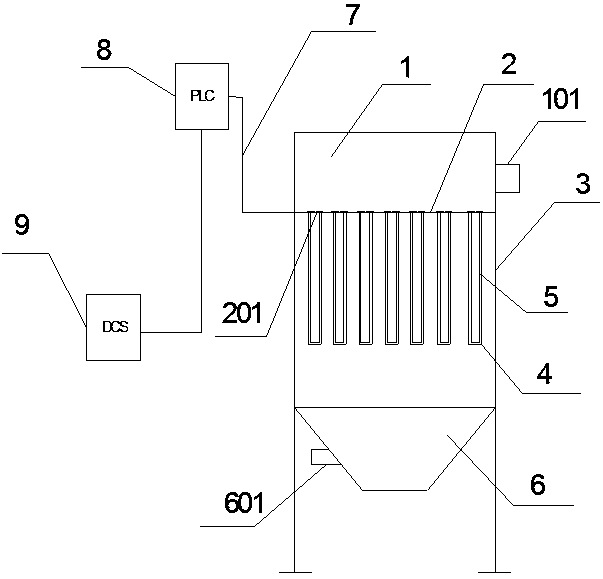

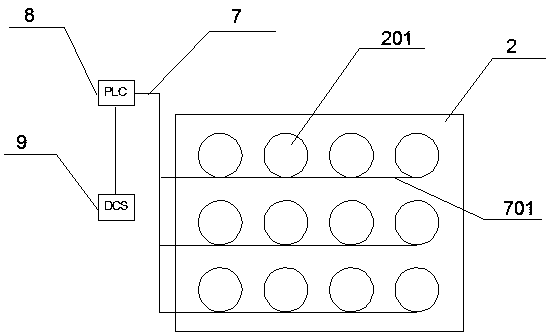

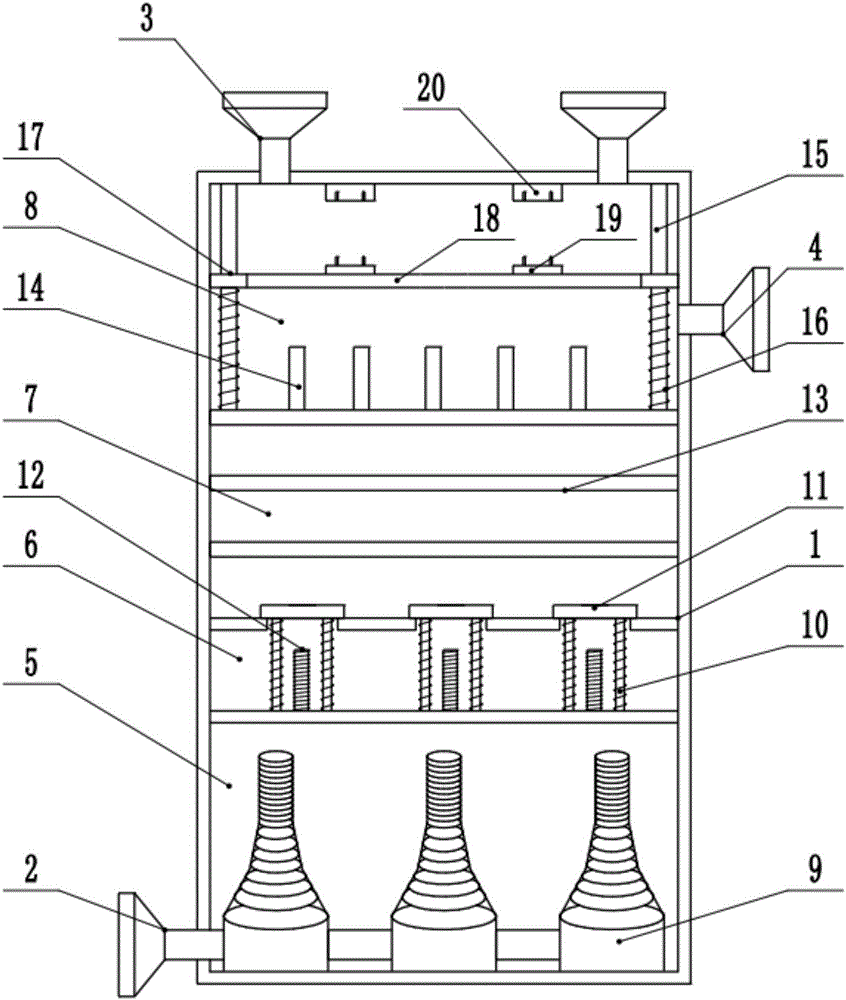

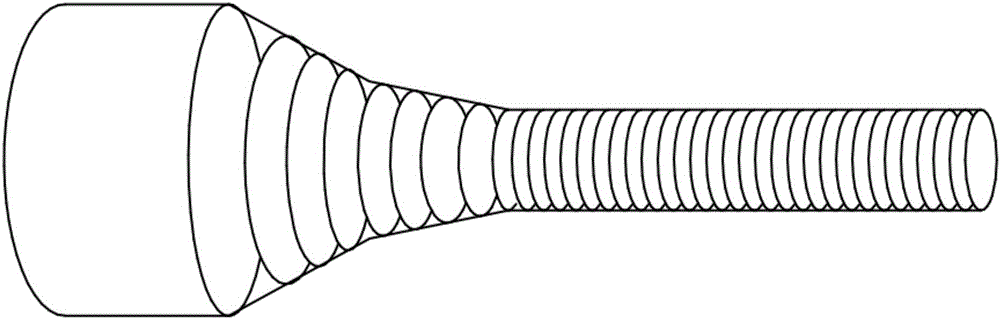

Intelligent alarm bag type dust removing device

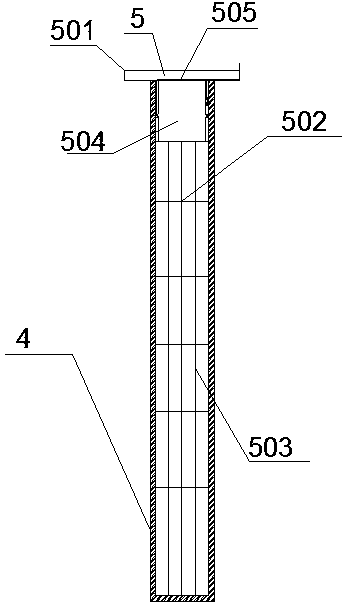

ActiveCN110812964AAvoid Excessive EmissionsHuman health protectionDispersed particle filtrationBaghouseEngineering

The invention provides an intelligent alarm bag type dust removing device, which device comprises an upper box body, a pattern plate, a middle box body, a cloth bag, a bag cage, a lower box body, a signal line, a PLC control cabinet and a DCS system, wherein a bag cage cap is arranged at the top of the bag cage, the bag cage is longitudinally provided with longitudinal ribs and is transversely provided with reinforcing rings, and a blowing protection device and a cloth bag performance monitoring system are arranged at the upper portion of the bag cage. According to the invention, by arrangingthe blowing protection device, the cloth bag can be protected from being damaged due to the improper installation of the blowing device; by arranging the cloth bag performance monitoring system in thecavity of the double-layer blowing protection device, laser with a certain intensity is emitted through the laser emitting device, if the cloth bag is damaged, dust penetrates through the cloth bag to cause the dust concentration in the cloth bag to exceed the standard, the intensity of the laser reaching the receiver is weakened due to the scattering effect of the dust, and the signal is transmitted to the PLC control cabinet and the DCS system after being processed by the signal processor; and if the cloth bag is damaged in the operation process of the dust removing device, the damaged cloth bag can be directly positioned, the alarm is given out, and the operator can immediately determine the position of the damaged cloth bag in the DCS system and replace the damaged cloth bag.

Owner:南京科赫科技有限公司

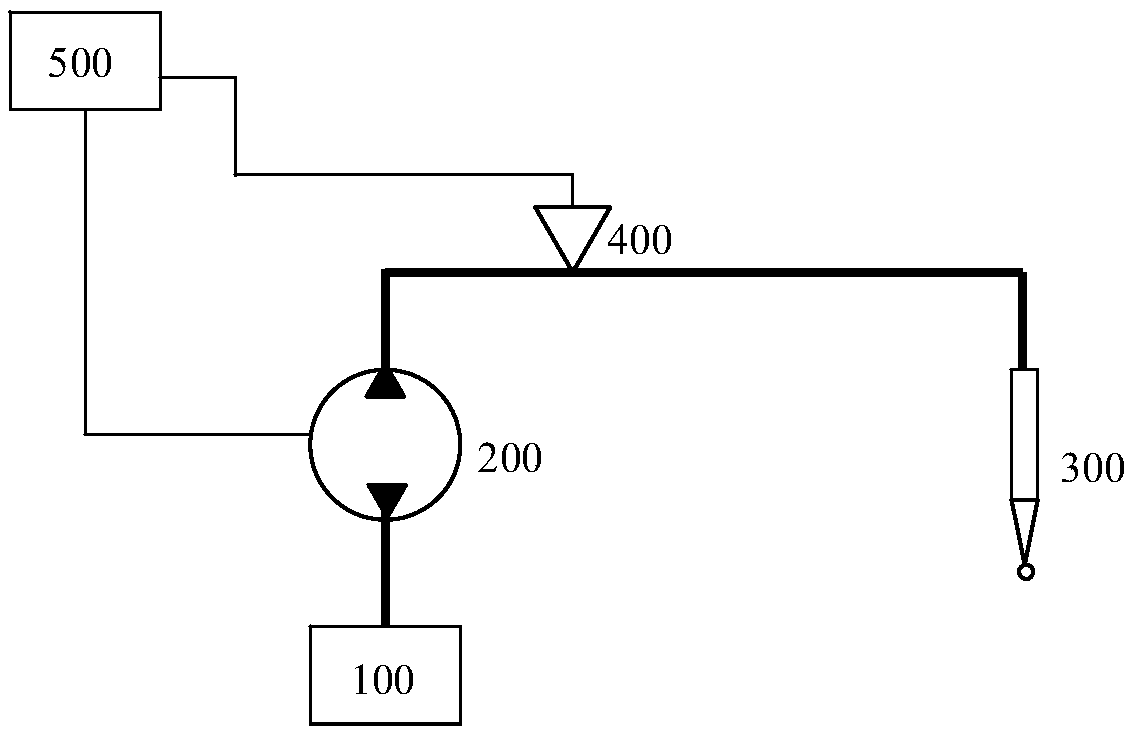

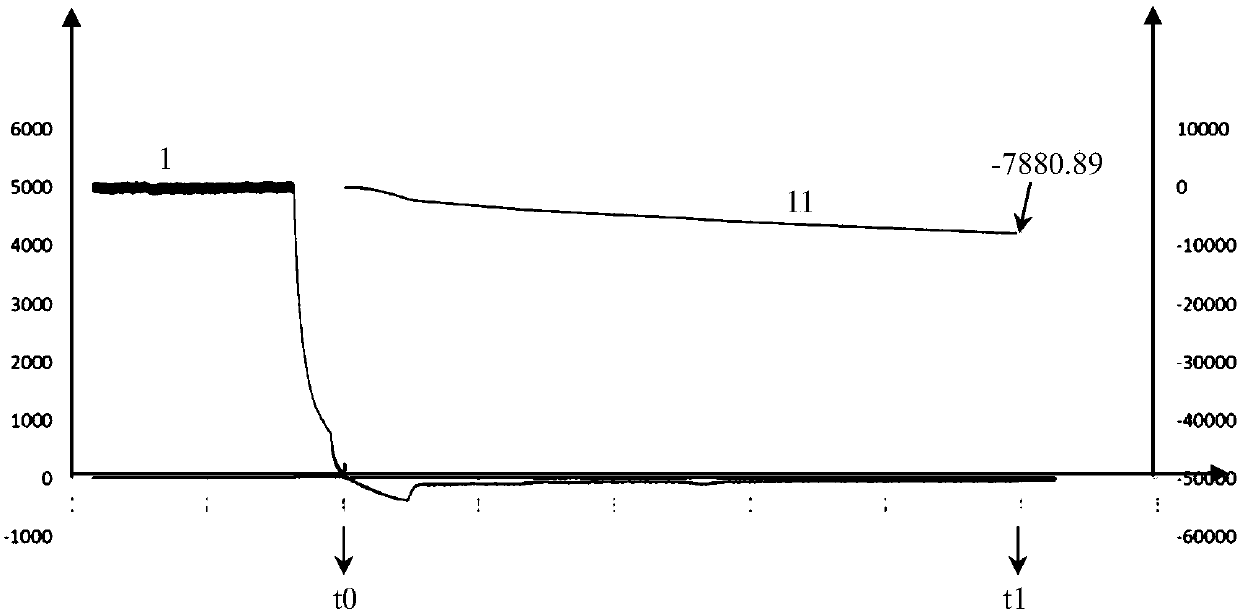

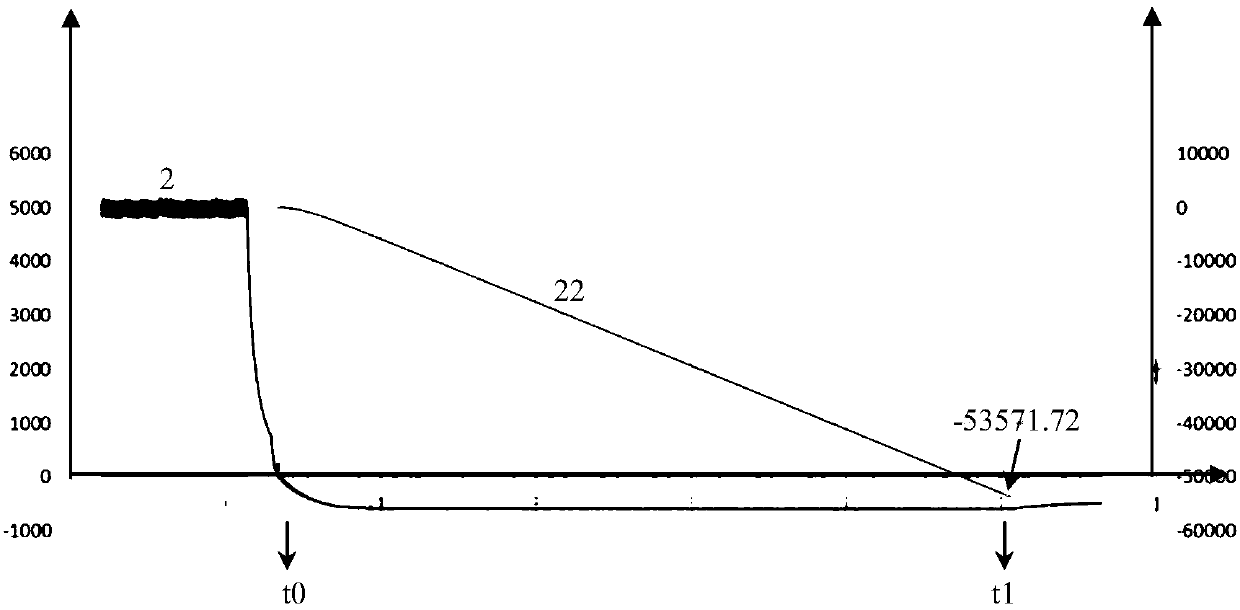

Spraying nozzle blocking diagnostic system and method for urea water solution spraying system

ActiveCN109869217AAvoid Excessive EmissionsInternal combustion piston enginesExhaust treatment electric controlSpray nozzleEngineering

The invention provides a spraying nozzle blocking diagnostic system and method for a urea water solution spraying system. The urea water solution spraying system comprises a liquid storing tank, a spraying nozzle, and a pump connected between the liquid storing tank and the spraying nozzle through a fluid pipeline. The spraying nozzle blocking diagnostic system comprises a sensor module used for detecting fluid pressure in the fluid pipeline, and a control module used for receiving and analyzing a pressure detecting value of the sensor module and controlling the pump. The control module can control the pump to be started n times so that the spraying nozzle can pump back, wherein n is an integer and is larger than or equal to 1. For each time of pumping back process of the spraying nozzle,within a certain preset time interval, the sensor module detects the pressure value in the fluid pipeline, the detected pressure value is integrated through the control module, thus an integration value is obtained, and the control module judges whether the spraying nozzle is blocked or not and / or judges the blocking degree of the spraying nozzle according to n integration values obtained on the such basis.

Owner:ROBERT BOSCH GMBH

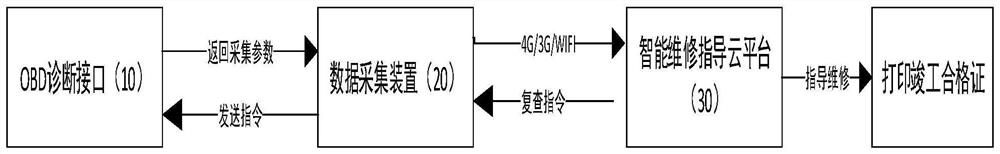

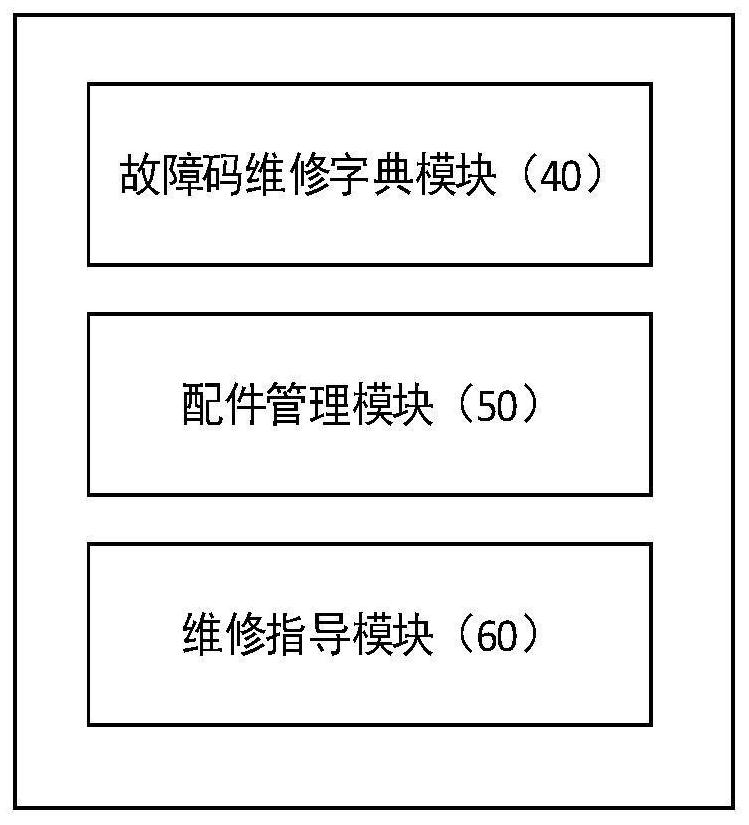

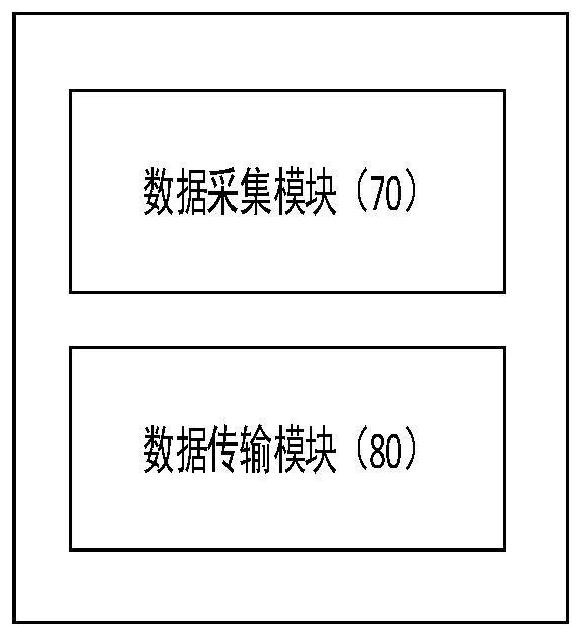

OBD-based intelligent motor vehicle maintenance guidance system

PendingCN111931954APrecise positioningSolve excessive vehicle emissionsRegistering/indicating working of vehiclesAutomotive engineeringCollections data

The invention provides a motor vehicle intelligent maintenance guidance system based on OBD. The system comprises a data collection device and an intelligent maintenance guidance platform which are connected, the data collection device comprises a data collection module and a data transmission module, and the intelligent maintenance guidance cloud platform comprises a fault code maintenance dictionary module, an accessory management module and a maintenance guidance module. According to the invention, accurate positioning of vehicle faults is realized, the problems of over-standard emission, incomplete maintenance and the like of vehicles are solved, the quality of maintenance personnel is improved, thorough maintenance of vehicles is ensured, and emission of automobile exhaust pollutantsis reduced.

Owner:CATARC AUTOMOTIVE TEST CENT TIANJIN CO LTD +1

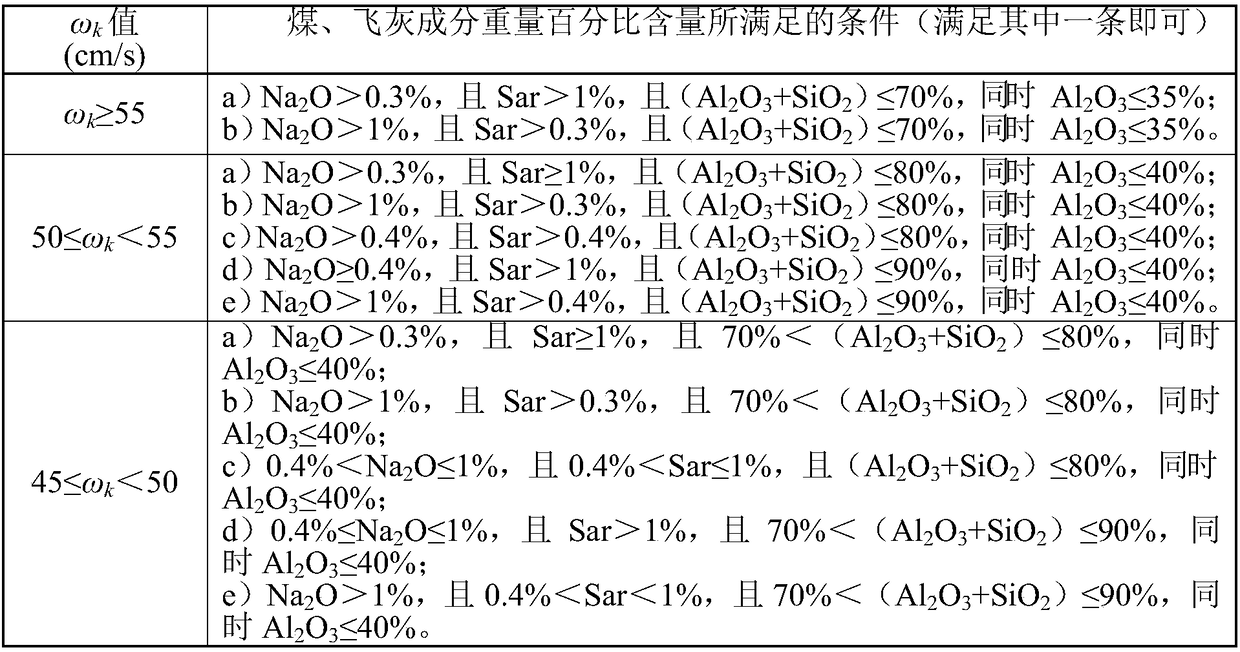

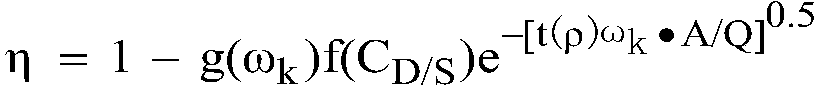

Method for selecting model of electrostatic dust collector for deeply cooling flue gas

ActiveCN108889452AAccurate calculation of dust removal efficiencyPrecisely select the modelCombustion technology mitigationElectrostatic separation detailsModel selectionSpecific model

The invention discloses a method for selecting a model of an electrostatic dust collector for deeply cooling flue gas. The method comprises the following steps: calculating an ash sulfur ratio, takingan apparent migration velocity of a coal, calculating an effect-raising influence factor, calculating the effect-raising influence factor of the apparent migration velocity and calculating the effect-raising influence factor of the apparent migration velocity of a rotary electrode pair, according to a present coal model and design parameter requirements; calculating a dust-collecting area acquired by the electrostatic dust collector according to a calculation mode for the dust collecting efficiency of the electrostatic dust collector; selecting a suitable electrostatic dust collector model. The invention has the advantages that main influence factors and rule of the dust collecting efficiency of the electrostatic dust collector for deeply cooling flue gas are excavated; a specific calculation formula is provided for accurately calculating the dust collecting efficiency and specific model of the electrostatic dust collector for deeply cooling flue gas; the dust emission at an outlet exceeding standard caused by smaller model selection design and the waste problems of materials, sites, running power consumption and the like, caused by oversize model selection design can be avoided.

Owner:浙江菲达环保科技股份有限公司

Self-regulation cut-in type efficient composite dust removal device

The invention discloses a self-regulation cut-in air inlet type efficient composite dust removal device, which comprises a device body, wherein a plurality of separation cones are arranged in a cyclone sedimentation region; fine holes are formed in the bottom of a gravity sedimentation region; an opening is formed in the top in the gravity sedimentation region; the surface of the opening is abutted against a magnetic plate; an electromagnet is arranged right under the magnetic plate and is positioned at the bottom of the gravity sedimentation region; fine holes are formed in the bottom of an electrostatic adsorption region; guide posts are arranged at two sides in the electrostatic adsorption region; a moving element sleeves each guide post; a moving plate is fixedly connected onto each moving element; micropores are uniformly distributed in the moving plate; a power supply plug is fixed on the surface of the moving plate; a socket is fixed on the inner wall of the top of the device body. The device has the advantages that dust in smoke gas can be effectively removed through cyclone and cloth bag filtering effects; the dust removal efficiency is high; the dust removal effect is good; after a cloth bag assembly is burnt, the device can be switched to an electrostatic adsorption dust removal mode for dust removal; the condition that the smoke gas dust discharged in a standard exceeding way due to the cloth bag burning is avoided.

Owner:HEFEI WISDOM DRAGON MACHINERY DESIGN CO LTD

Splashing rust removing device with active carbon

InactiveCN106582169AWith synchronous processing functionReduce labor intensityCombination devicesSpraying apparatusActivated carbonSlag

The invention discloses a splashing rust removing device with active carbon. The splashing rust removing device is mainly composed of an insulating tank, splashing rust removers and a control device. An air inlet and a material discharging opening are formed in the lower portion of the insulating tank respectively, the air inlet is connected with a sand blasting machine, the internal bottom of the insulating tank is filled with a solvent, a baffle plate is arranged above the solvent, an air discharging pipe at the top of the insulating tank is connected with the splashing rust removers through a flange, grid plates, cloth bag dust removing devices and purifier devices are arranged in the splashing rust removers from bottom to top, an air discharging opening and a pollutant detection device are arranged at the top of the splashing rust removing device, slag discharging pipes at the bottoms of the splashing rust removers are connected with the insulating tank through safety valves, and a control device is connected with all single channel switches. The splashing rust removing device has the paint drop, dust and VOC synchronous treating function, the treating effect and pressure can be automatically monitored and adjusted, the VOC treating rate is larger than 99.5%, the device is simple in structure, and the processing cost is low.

Owner:DONGGUAN ZHIPEI ELECTROMECHANICAL TECH CO LTD

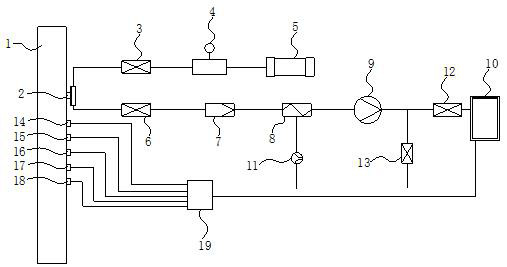

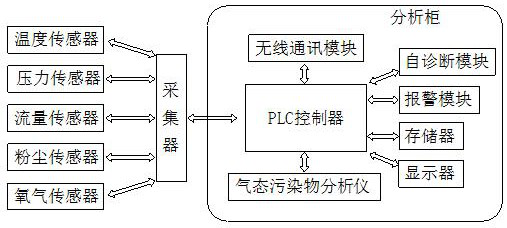

Industrial waste gas detection system

PendingCN112729976AGuaranteed accuracyEnsure reliabilityAnalysing gaseous mixturesWithdrawing sample devicesAir compressionFlue gas

The invention relates to the technical field of waste gas detection and discloses an industrial waste gas detection system. The system comprises a flue, a gas sampling probe, an electromagnetic valve, a wattmeter, an air compression pump, an electric ball valve, a filter, a condenser, a sucking pump and an analysis cabinet, wherein the gas sampling probe is installed on the flue, the electromagnetic valve is communicated with the gas sampling probe through a pipeline, the wattmeter is communicated with the electromagnetic valve through a pipeline, and the air compression pump is communicated with the wattmeter through a pipeline. According to the industrial waste gas detection system, under the operation of a sucking pump, waste gas in a flue passes through a filter and a condenser under the collection of a gas sampling head, the waste gas is cooled, and particles in the waste gas are removed, so that the waste gas is guided into an analysis cabinet for detection, and ultra-clean, constant-temperature and constant-flow stable gas is obtained; therefore, accuracy and reliability of the analyzer are ensured.

Owner:广东正州环保科技股份有限公司

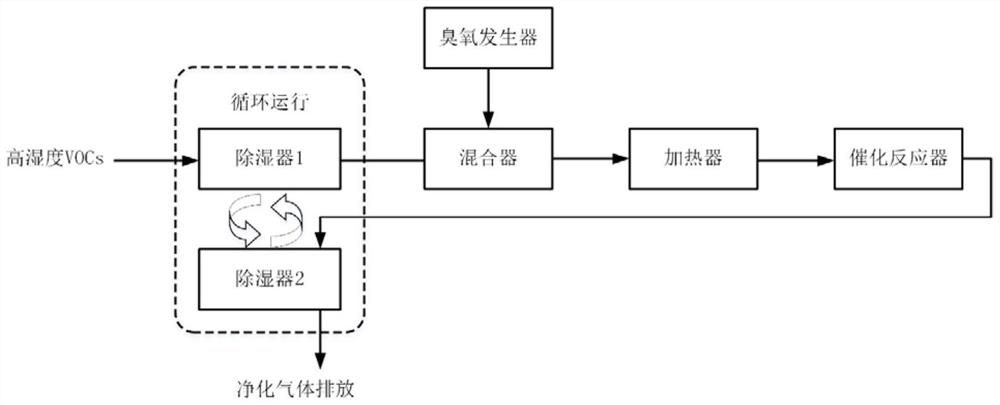

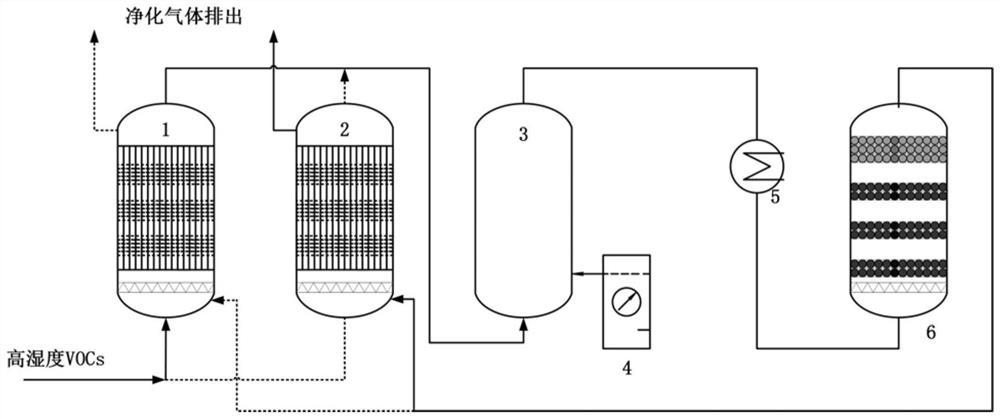

Method for low-temperature catalytic ozone treatment of high-humidity organic waste gas

InactiveCN113509825ASolving activityGuaranteed uptimeGas treatmentDispersed particle separationHigh humidityPtru catalyst

The invention discloses a method for low-temperature catalytic ozone treatment of high-humidity organic waste gas, and belongs to the field of waste gas treatment. According to the method, firstly, high-humidity organic waste gas is dehumidified by a water absorbent, the dehumidified organic waste gas is properly heated by a heating device and then is mixed with ozone, and a degradation reaction is carried out in a catalyst bed layer, so that direct contact between a large amount of water and a catalyst is avoided, and the degradation efficiency of the organic waste gas, the stability of the catalyst are improved, and the long-term stable operation of the device is ensured; and meanwhile, the reaction tail gas with a certain temperature is used for regenerating the water absorbent, so that the heat is fully utilized, and the energy consumption is reduced.

Owner:NANJING UNIV +1

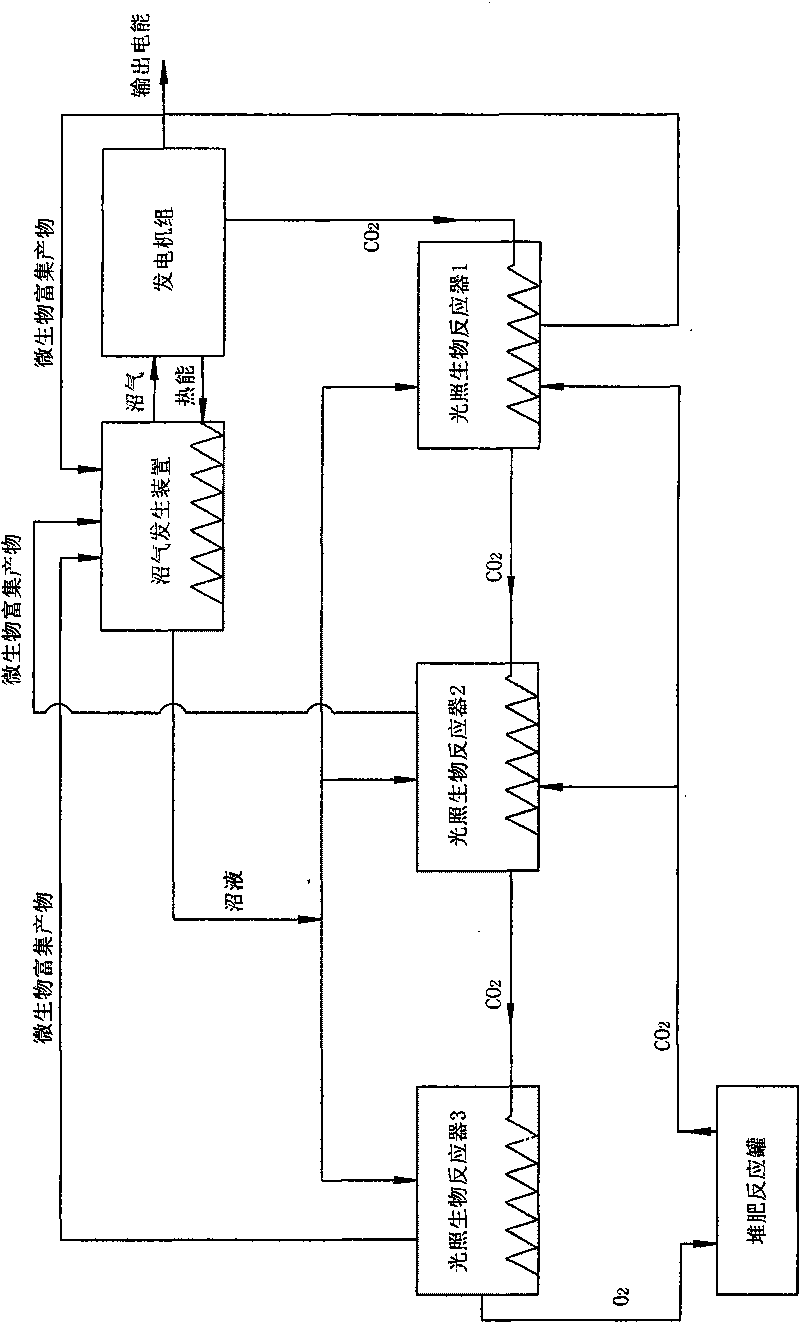

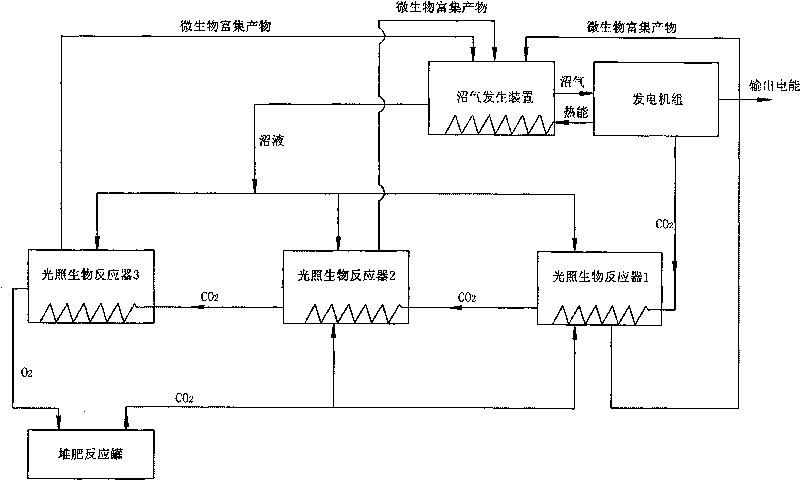

Microorganism power generating method by utilizing carbon source in a recycling way

InactiveCN101749106AGood breeding conditionsFull of nutritionInternal combustion piston enginesWaste based fuelNutrient solutionInternal combustion engine

The invention discloses a microorganism power generating method by utilizing carbon source in a recycling way, comprising the following steps: a) nutritional type microorganisms of light are placed in an illumination bioreactor, liquid nutrient solution is added, carbon dioxide gas is introduced, the microorganism enrichment products at the upper part of the floating illumination bioreactor are output; b) the microorganism enrichment products are input in a methane generator, the generated methane liquid is input in the illumination bioreactor, and the generated methane is input in a combustion motor in a generator set for burning; c) the output carbon dioxide gas is input to the illumination bioreactor. In the method, the luminous energy nutritional type microorganisms are used as primary material for marsh gas power generation, non-renewable resources are not consumed, and harmful gas is not exhausted. By adopting the way of circulating utilization, all products in the process flow can be used.

Owner:刘爱平

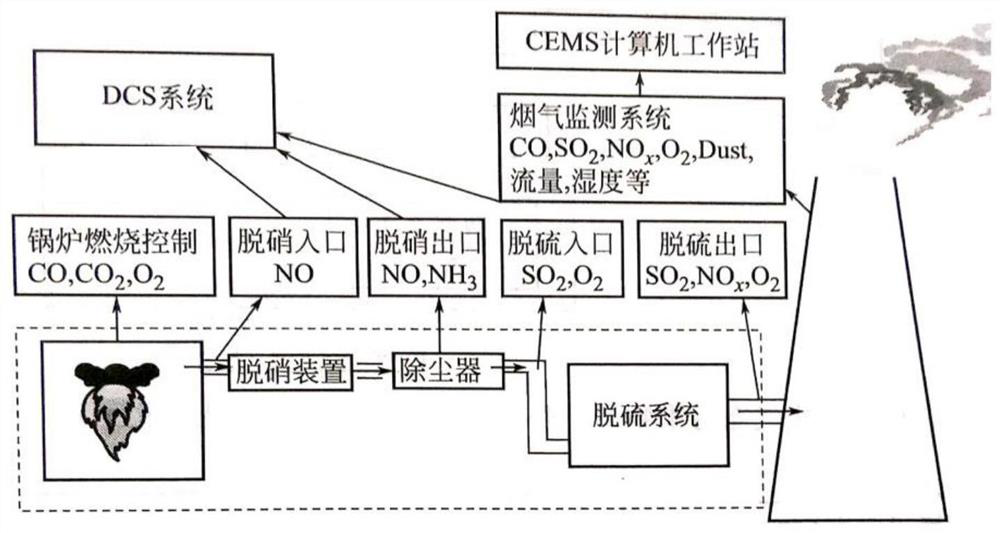

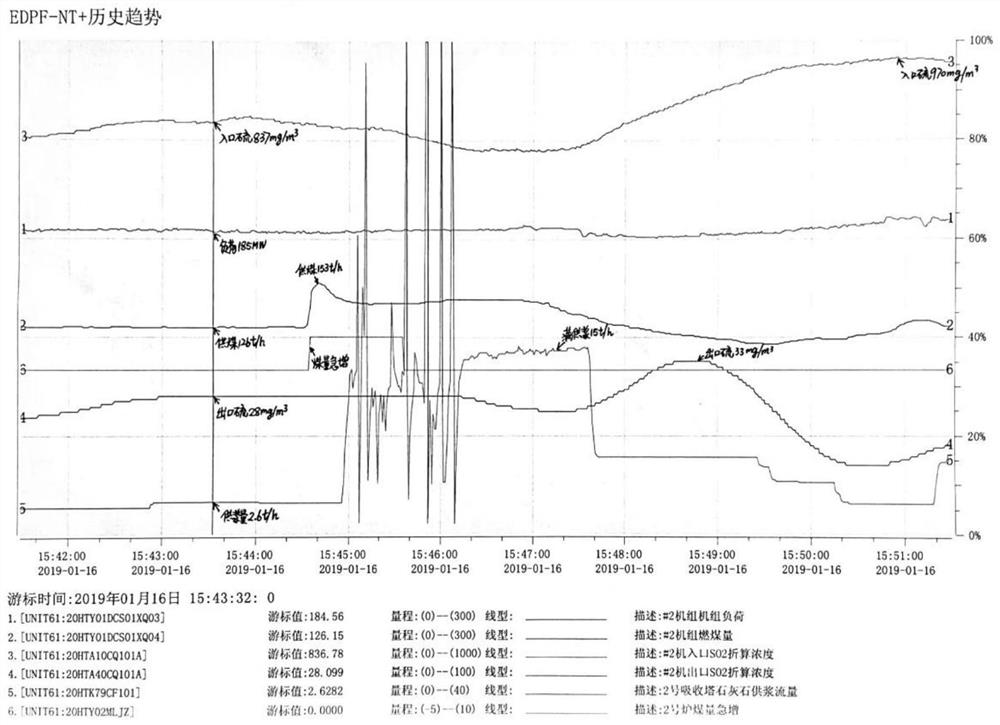

Early warning method and early warning system for preventing SO2 standard-exceeding emission of desulfurized flue gas and application of early warning method and early warning system

ActiveCN111613019ASolve the hysteresisEliminate Excessive EmissionsGas treatmentDispersed particle separationSulfur dioxideCoal

The invention provides an early warning method and an early warning system for preventing SO2 standard-exceeding emission of desulfurized flue gas and application of the early warning method and the early warning system. The early warning method comprises the steps that S1 the coal feeding amount is detected in real time, and the current coal feeding amount is obtained; S2 the difference value ofthe previous coal feeding amount before the current coal feeding amount exceeds the preset time is obtained; S3 an alarm is given when the difference value is greater than a preset value, wherein theearly warning system comprises a coal feeding amount real-time detection module, a data processing module and an alarm module. The coal feeding amount real-time detection module detects the coal feeding amount in real time and sends an obtained coal feeding amount signal to the data processing module. The data processing module obtains the difference value of the previous coal feeding amount before the current coal feeding amount exceeds the preset time and sends an early warning signal to the alarm module when the difference value is larger than the preset value. The alarm module gives an alarm when receiving the early warning signal. According to the early warning method and system, the problems of operation adjustment lag and the like of a desulfurization system are solved, excessive emission of sulfur dioxide is effectively avoided, and the operation economy is improved.

Owner:DATANG ENVIRONMENT IND GRP

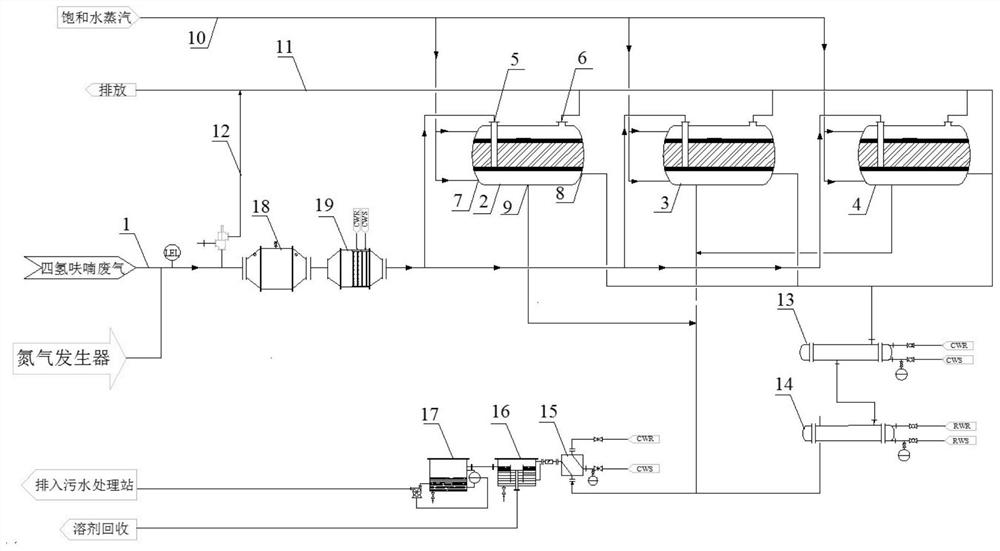

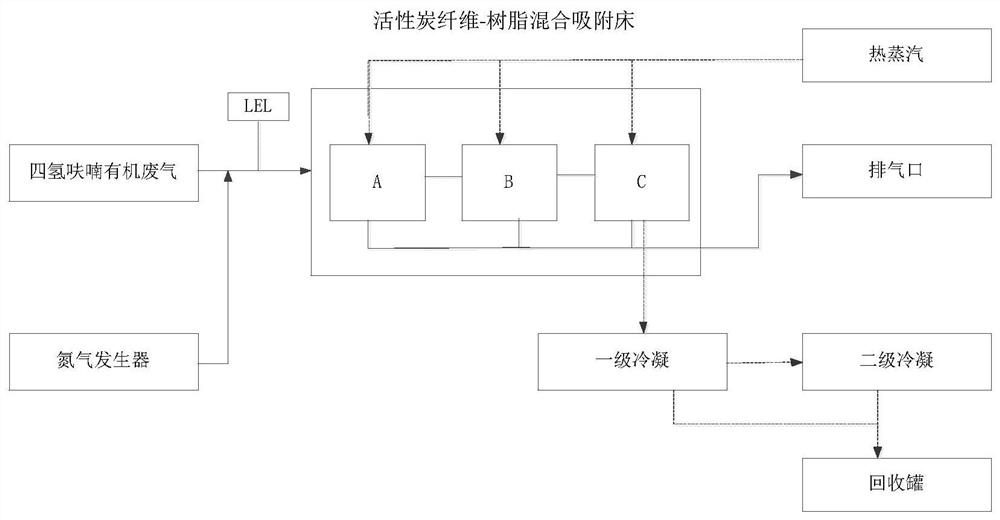

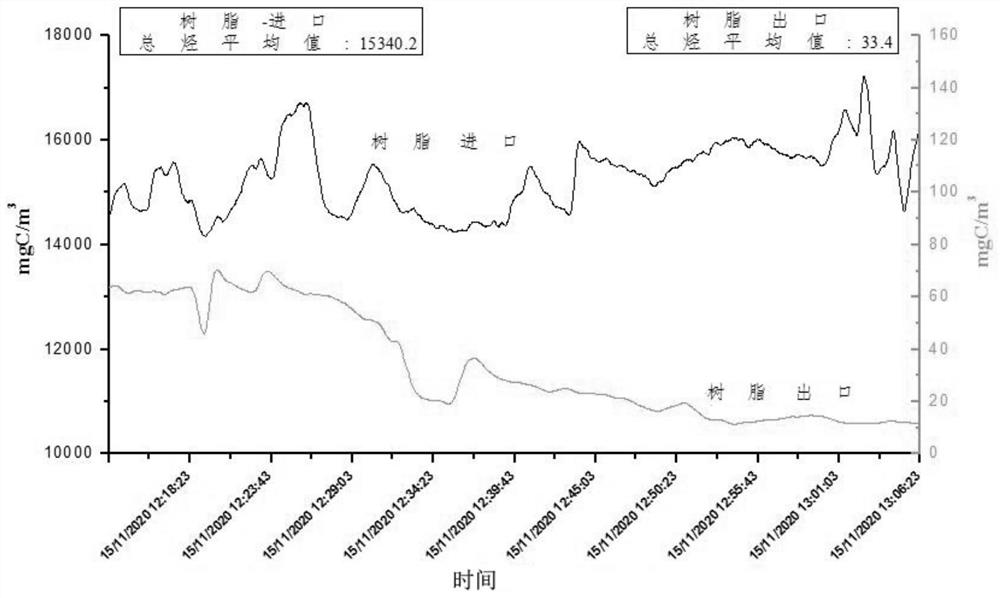

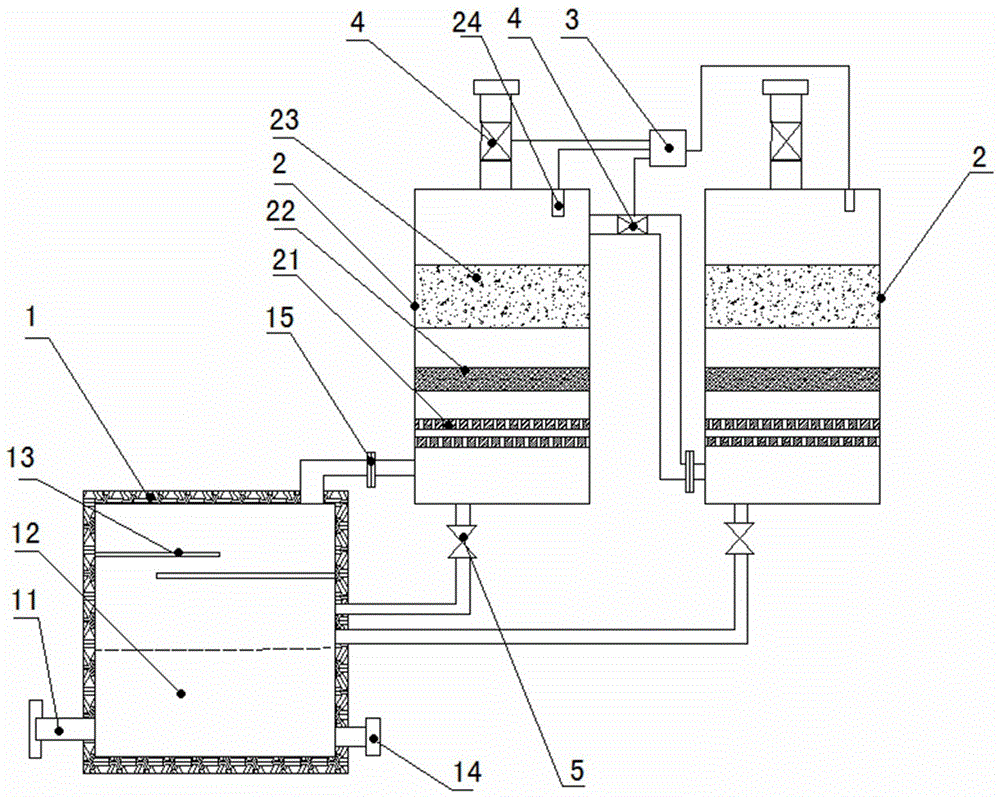

High-concentration tetrahydrofuran organic waste gas treatment process and device

InactiveCN112657310AAvoid mixingGreat driving forceDispersed particle separationFiberNitrogen generator

The invention discloses a high-concentration tetrahydrofuran organic waste gas treatment process and device, and belongs to the technical field of waste gas treatment. The device comprises a gas conveying device, an adsorption device, an LEL online monitoring device, a desorption device, a vacuum pump and a condensation recovery device, a nitrogen generator is arranged on the gas inlet pipeline; the adsorption device comprises at least two adsorption tanks which are arranged in parallel and have the same structure, and the adsorption material is a resin and activated carbon fiber composite layer; the LEL online monitoring device is connected with the gas conveying device, the adsorption device, the desorption device and the vacuum pump; the vacuum pump is connected with the adsorption tank; and the adsorption device and the desorption device are connected with the condensation recovery device. When the device is used for waste gas treatment, the LEL online monitoring device detects the concentration of waste gas in real time, the whole process is adjusted and controlled by the controller, and residual high-concentration waste gas in the valve switching process is rapidly adsorbed through activated carbon fibers. The whole treatment process system is in a low-oxygen state, the safety is improved, and the treatment efficiency and the solvent recovery rate are high.

Owner:江苏齐清环境科技有限公司

Spattering rust removing device provided with corrosion-resistant layer

InactiveCN106582192AWith synchronous processing functionReduce labor intensityCombination devicesGas treatmentSlagTherapeutic effect

The invention discloses a spattering rust removing device provided with a corrosion-resistant layer. The spattering rust removing device mainly comprises a partitioning tank, a spattering rust remover and a control device, wherein an air inlet and a discharge hole are respectively formed in the lower part of the partitioning tank; the air inlet is connected with a sand blasting machine; the bottom inside the partitioning tank is filled with a solvent; a baffle plate is arranged above the solvent; an exhaust tube at the top of the partitioning tank is connected with the spattering rust remover through a flange; a grid plate, a cloth bag dust collection device and a purifier device are arranged from bottom to top inside the spattering rust remover; an exhaust hole is formed in the top of the spattering rust remover; a pollutant detection device is arranged at the top of the spattering rust remover; a slag discharge tube at the bottom of the spattering rust remover is connected with the partitioning tank through a safety valve; the control device is connected with each single channel switch. The spattering rust removing device has a function of synchronous treatment on paint droplets, dust and VOC (volatile organic compounds), treatment effects and pressure can be automatically monitored and adjusted, the VOC treatment rate is greater than 99.5%, and the spattering rust removing device is simple in structure and low in manufacturing and processing cost.

Owner:DONGGUAN ZHIPEI ELECTROMECHANICAL TECH CO LTD

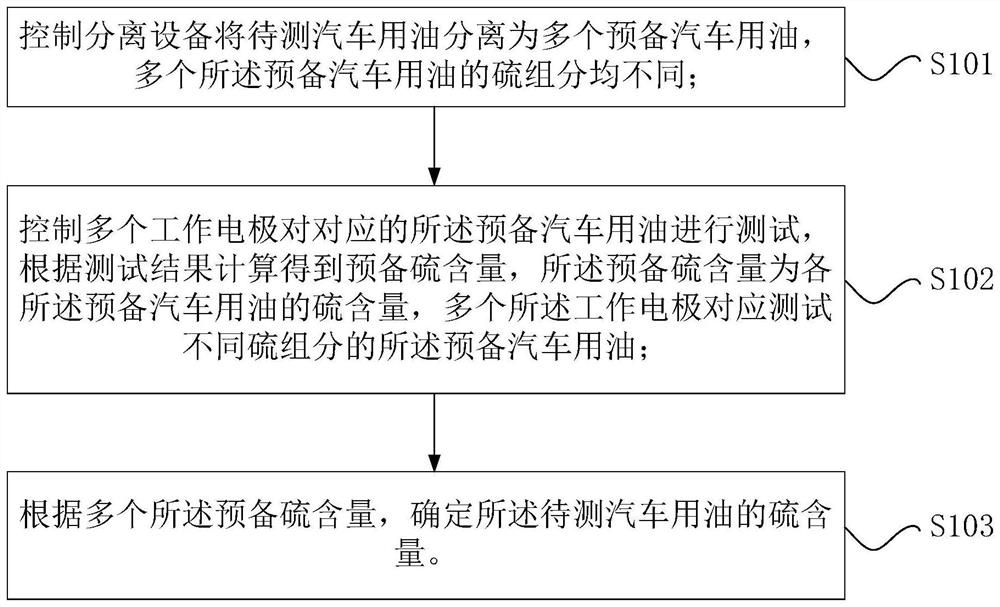

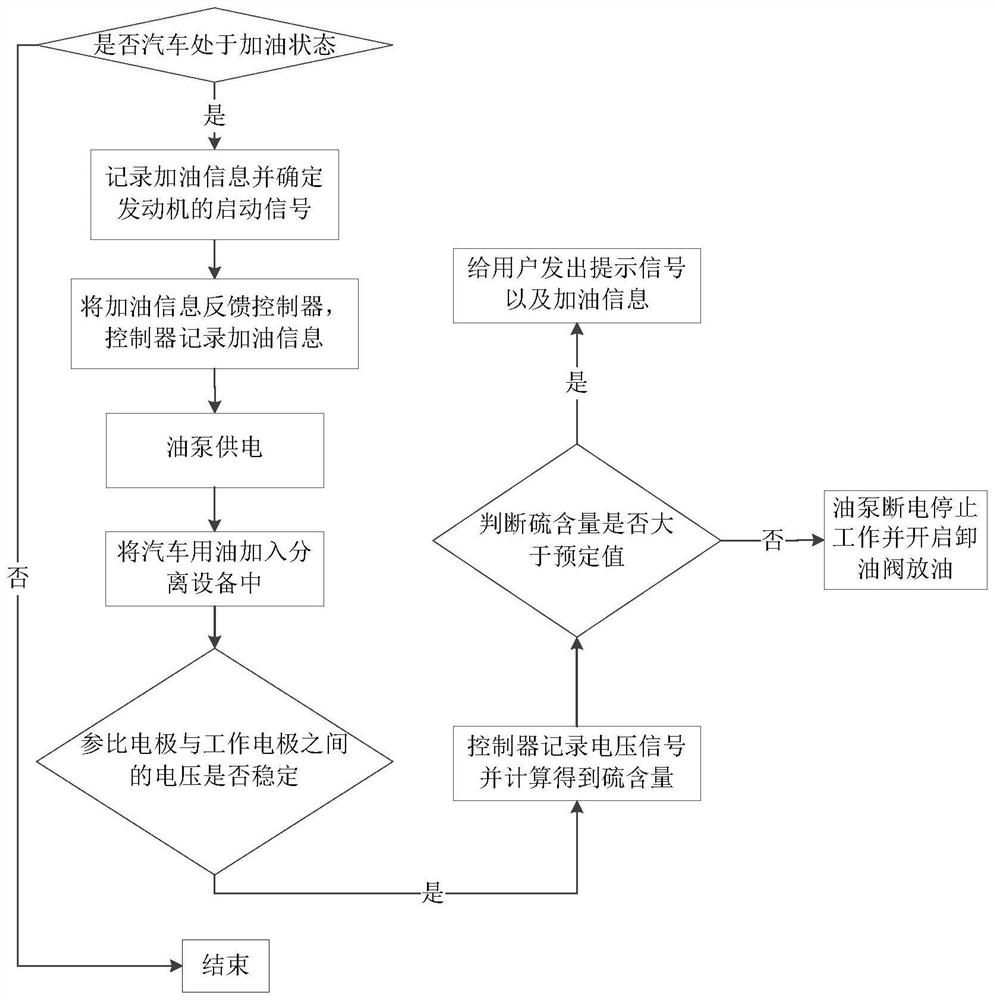

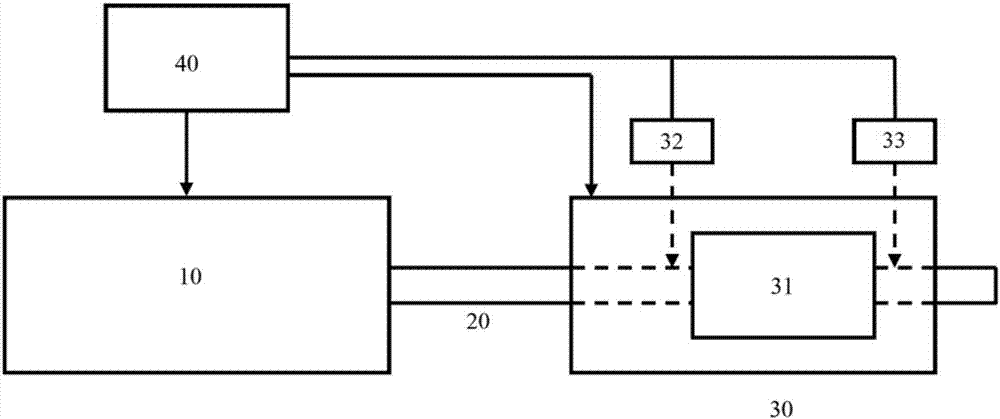

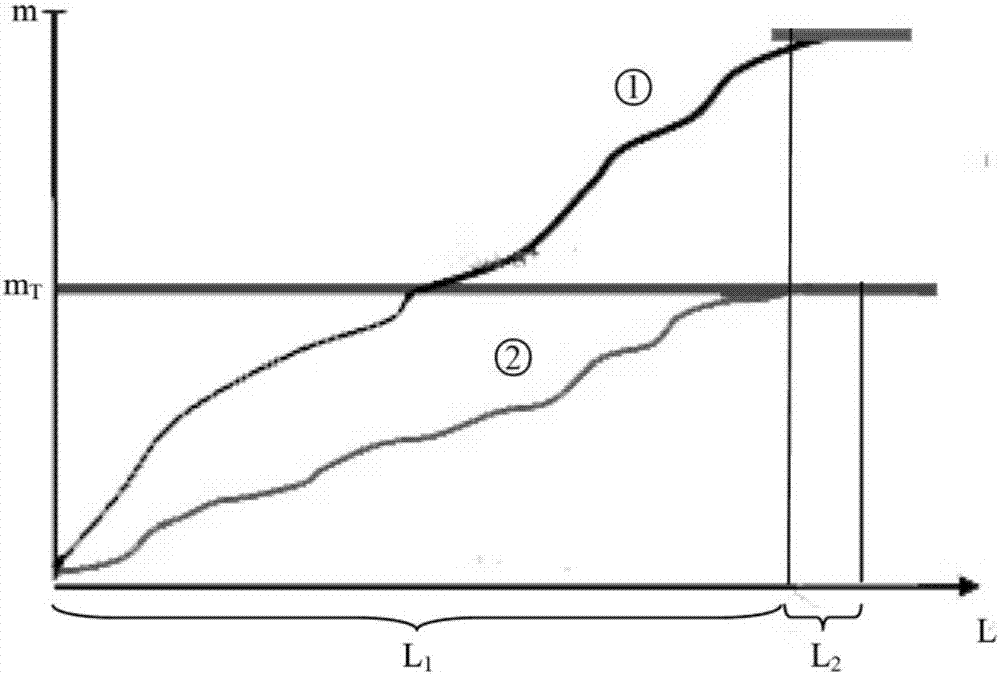

On-line detection method and detection device for sulfur content of automobile oil

PendingCN114689824AAddressing deficiencies in quality monitoringAvoid corrosionMaterial testing goodsOil canOil separation

The invention provides an on-line detection method and device for the sulfur content of automobile oil, and the method comprises the steps: firstly, controlling separation equipment to separate to-be-detected automobile oil into a plurality of pieces of prepared automobile oil, the sulfur components of the plurality of pieces of prepared automobile oil being different; then, the multiple working electrodes are controlled to test the corresponding prepared automobile oil, the prepared sulfur content is calculated according to the test result, the prepared sulfur content is the sulfur content of each prepared automobile oil, and the multiple working electrodes correspondingly test the prepared automobile oil with different sulfur components; and finally, determining the sulfur content of the to-be-detected automobile oil according to the plurality of prepared sulfur contents. A plurality of working electrodes ensure that the accuracy of sulfur content detection is high, the sulfur content of the automobile oil can be quickly detected on line, and the defect that the quality of the automobile oil cannot be monitored in real time by an existing off-line detection method is overcome; the problems that emission exceeds the standard, engine parts are corroded and the oil change period is shortened due to the fact that monitoring is not in time are solved.

Owner:WEICHAI POWER CO LTD

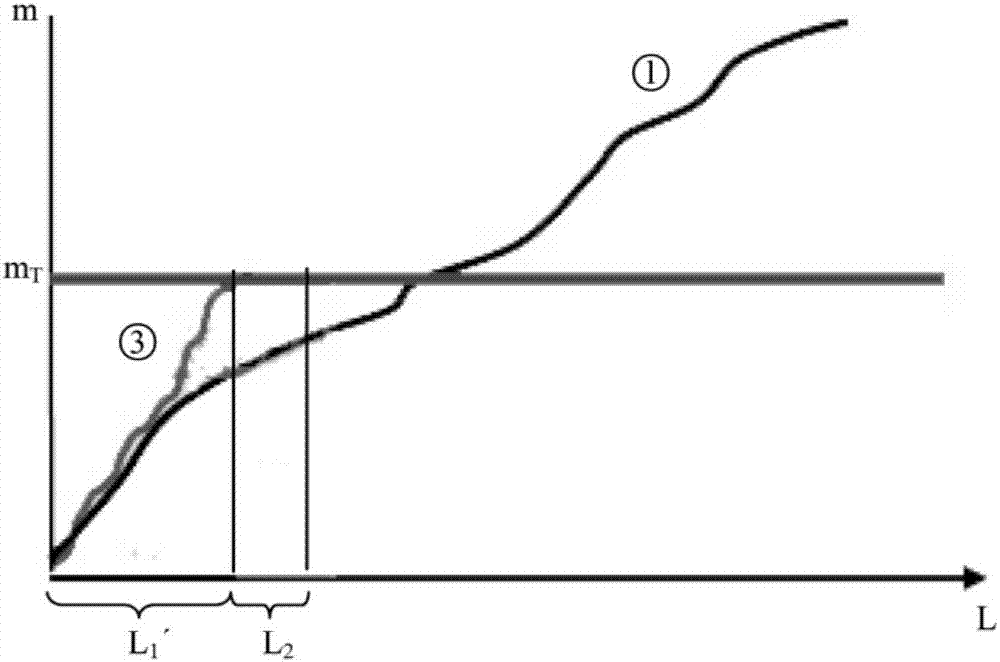

Frequent regeneration diagnosis method for diesel particle filter

PendingCN107345495AHigh regeneration frequencyAvoid Excessive EmissionsInternal combustion piston enginesExhaust apparatusDiagnosis methodsDiesel fuel

The invention discloses a method for diagnosing whether regeneration of a diesel particle filter of a diesel vehicle is frequent or not. Scheduled work condition parameters and a scheduled recording period set in advance in the S10 and S20 and the maximum allowed frequency, pre-determined on the basis of the waste gas exhaust requirement of the diesel vehicle in the S30, of regeneration of the diesel particle filter within the recording period are stored in a diesel vehicle. The method comprises the steps that the completing frequency of regeneration of the diesel particle filter is recorded in the recording period; in the S40, the recorded completing frequency is compared with the maximum allowed frequency, and in the S52, if the recorded completing frequency is larger than the maximum allowed frequency, frequent generation happens to the diesel particle filter; and in the S 51, if the recorded completing frequency is not larger than the maximum allowed frequency, it is confirmed that the regeneration frequency of the diesel particle filter is normal, meanwhile, the recording period is reset, and the completing frequency of generation of the diesel particle filter is recorded again.

Owner:ROBERT BOSCH GMBH

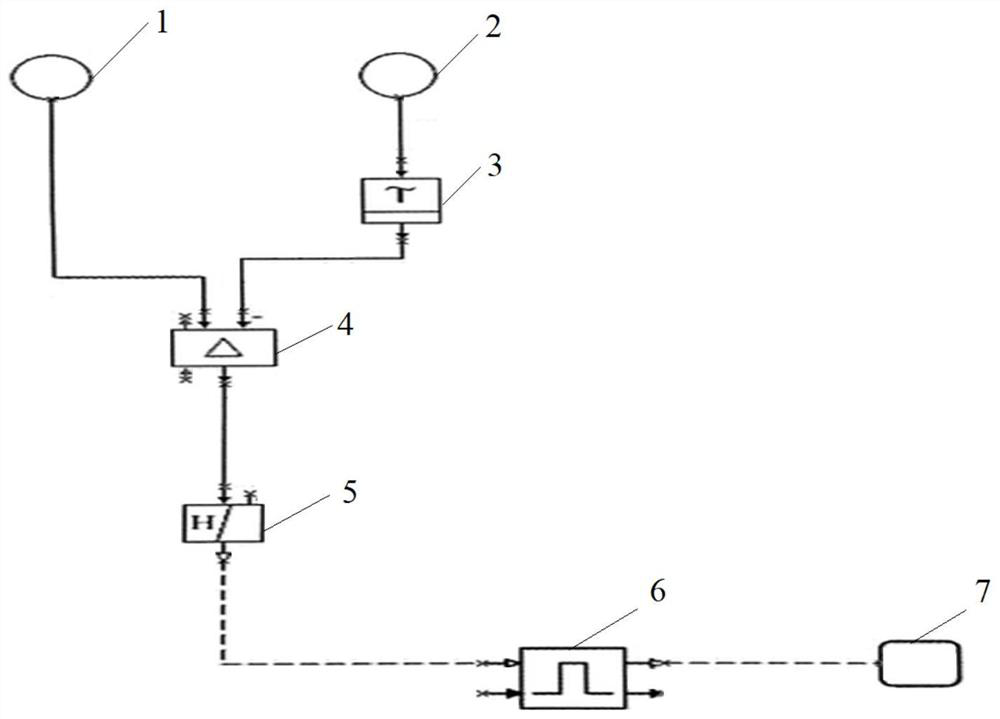

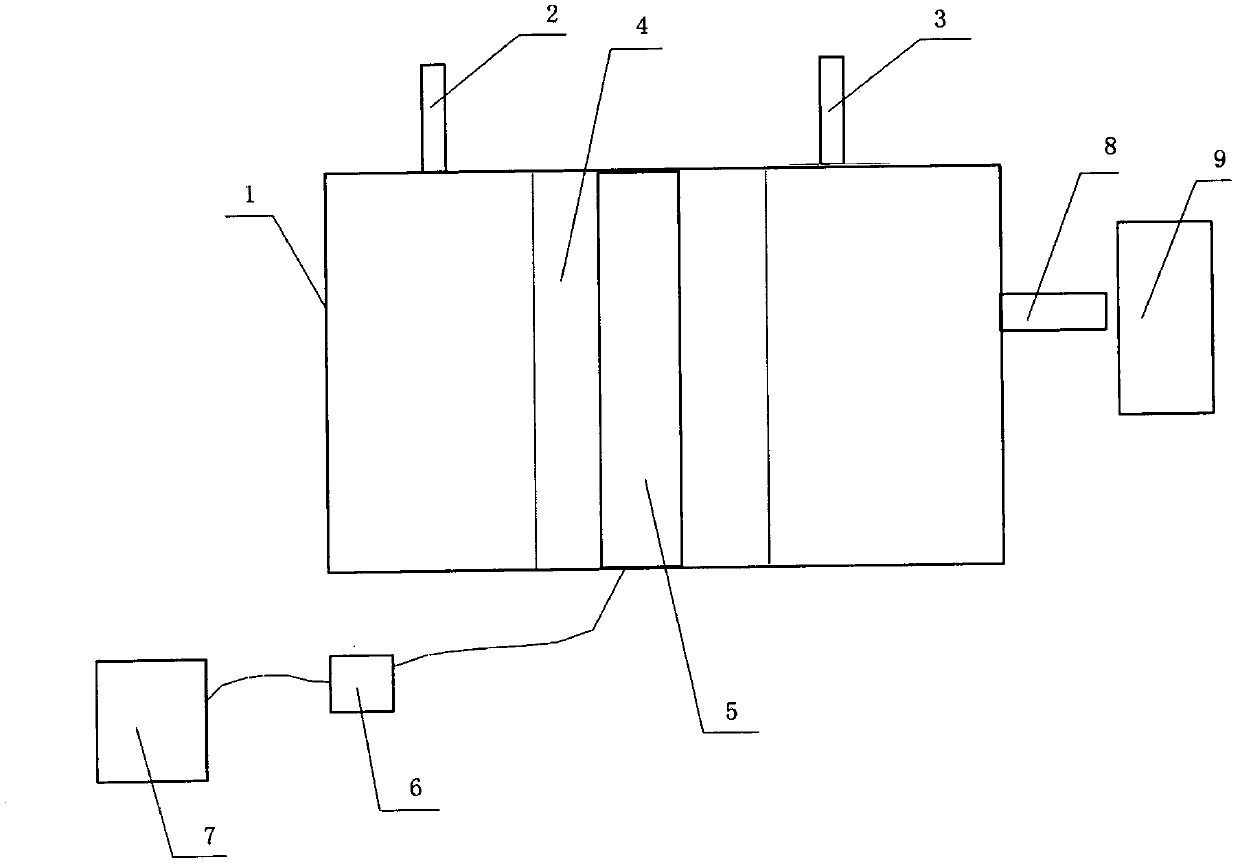

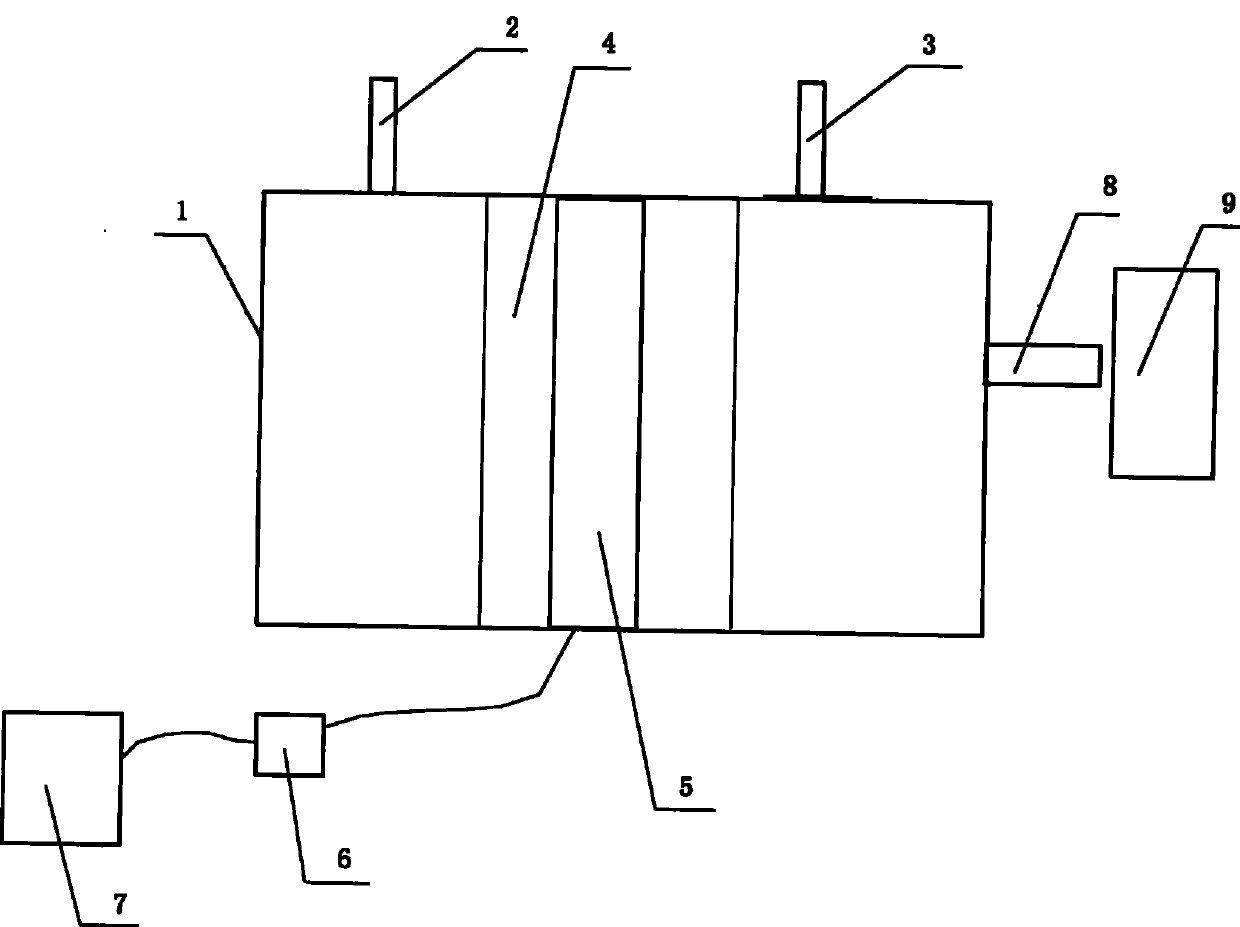

Automatically controllable fuel economizer of automobile

InactiveCN102606352ABurn fullyAvoid Excessive EmissionsElectrolysis componentsNon-fuel substance addition to fuelCombustion chamberAutomatic control

The invention discloses an automatically controllable fuel economizer of an automobile, which comprises an electrolytic cell (1). An anode (2) and a cathode (3) are respectively arranged on two sides of the inside of the electrolytic cell (1), an isolation area (4) is disposed between the anode (2) and the cathode (3), an ion switching device (5) is arranged in the isolation area (4), a controller (6) is connected onto the ion switching device (5), an input end of the controller (6) is connected with a vehicular computer (7), an output end of the controller (6) is connected with the ion switching device (5), the computer (6) is started by the vehicular computer (7), break-and-make of the ion switching device (5) is controlled by the controller (6) so as to electrolyze water, a ventilating pipeline (8) is arranged on a side surface of the electrolytic cell (1), and the electrolytic cell (1) is communicated with a combustion chamber (9) of an engine of the automobile via the ventilating pipeline (8). The automatically controllable fuel economizer of the automobile is simple in structure, fuel can be sufficiently combusted, and emission of tail gas is prevented from exceeding standards.

Owner:TAIZHOU XINGDONG COAL MINING MACHINERY

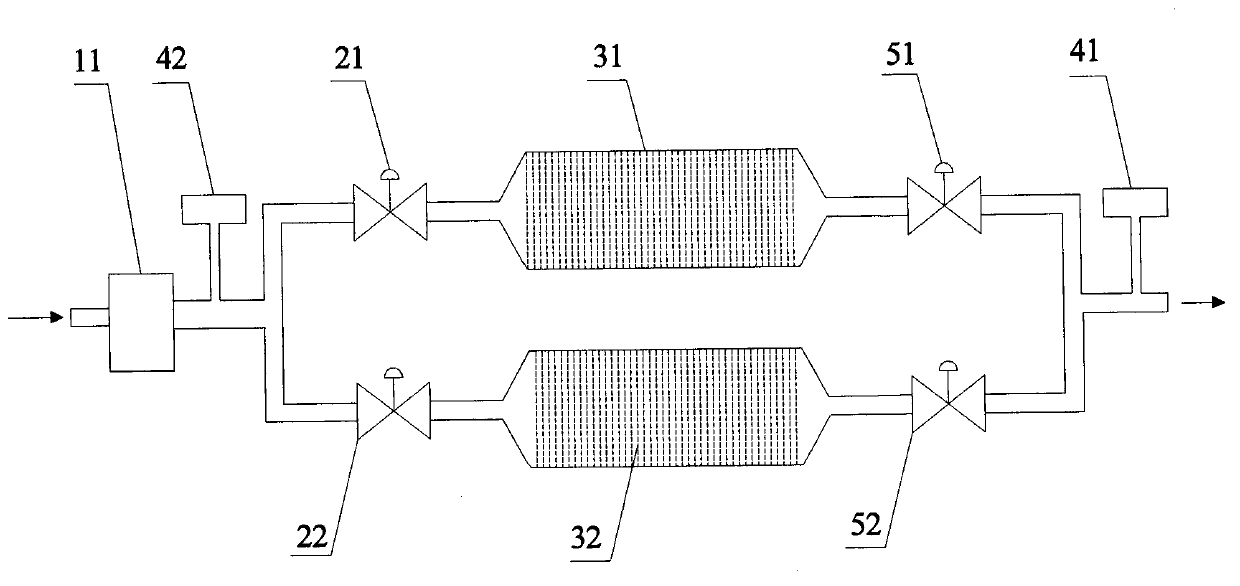

System for controlling dioxin emission in flue gas in real time and working method thereof

InactiveCN103691265AGuaranteed continuous operationGuaranteed uptimeDispersed particle separationFlue gasEngineering

The invention provides a system for controlling dioxin emission in flue gas in real time and a working method of the system. The system comprises a pre-treating device, a switching part and at least two dioxin removing devices, wherein the pre-treating device is used for removing dust, and acidy and smelly gases in the flue gas; the switching part is used for selectively communicating the outlet of the pre-treating device with one of the at least two dioxin removing devices; each dioxin removing device comprises a reactor, a valve, a first detector, a second detector and a judging module, wherein the reactor is used for removing dioxin in the flue gas; the valve is arranged at the downstream of the reactor; the first detector and the second detector are respectively used for detecting concentration of a dioxin precursor in the flue gas at the upstream and the downstream of the reactor, and outputting the value to the judging module; and the judging module is used for judging that whether switching is needed or not according to the received concentration value, and transmitting the result to the switching part and the valve. The system disclosed by the invention has the advantages of detecting in real time, continuously treating, preventing standard-exceeding emission, and the like.

Owner:葛守飞 +2

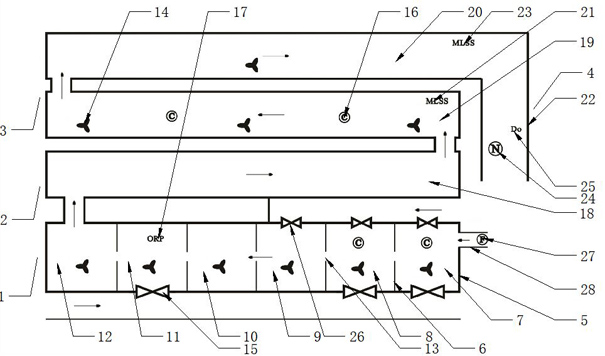

Multi-section AO enhanced denitrification sewage treatment system and application method thereof

PendingCN112158954AIncrease hydraulic retention timeChanging the denitrification timeWater treatment compoundsTreatment with aerobic and anaerobic processesWater treatment systemEnvironmental engineering

The multi-section AO enhanced denitrification sewage treatment system comprises a front-end anoxic section, a first aerobic section, a middle anoxic section and a second aerobic section which are sequentially arranged in the sewage flowing direction. Meanwhile, the invention further discloses an application method of the sewage treatment system based on multi-stage AO enhanced denitrification. Compared with the traditional AAO treatment process, the method has the advantages of 1) an anaerobic section being canceled, and adopting an anoxic-aerobic (AO) enhanced denitrification process; 2) adjusting the hydraulic retention time ratio of the anoxic zone to the aerobic zone, increasing the hydraulic retention time of the anoxic zone, and reducing the hydraulic retention time of the aerobic zone, and 3) adding a multi-point carbon source, through a series of measures, improving to a multi-stage AO enhanced denitrification process so as to enhance the denitrification capability and improvethe denitrification efficiency.

Owner:福州创源同方水务有限公司

A non-saponification method for extraction separation of nickel and cobalt

A non-saponification method for extraction separation of nickel and cobalt is provided. The method includes subjecting nickel- and cobalt-containing solid waste to high-temperature calcination, performing acid leaching to form an acid leachate, mixing synergistic extractants and a diluting agent, reacting the mixture with the acid leachate, and extracting the cobalt in the acid leachate to achievenickel-cobalt separation. No NaOH adopted as a saponifier is used in the method, thus avoiding excessive emission of saponification waste water. An acidic extractant B326 and an alkaline extractant methyl chloride N204 are synergistic under acidic conditions and the cobalt in the acid leachate is extracted into an organic phase effectively, thus achieving nickel-cobalt separation. For power battery solid waste the discharging amount of which is huge because power batteries are widely applied, the method is simple to operate and low in equipment requirements and has huge industrial practicality.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com