High-concentration tetrahydrofuran organic waste gas treatment process and device

A technology of organic waste gas and treatment device, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of easy escape of activated carbon, human and environmental hazards, safety accidents, etc., to prevent air mixing and prevent safety problems. , the effect of ultra-high security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

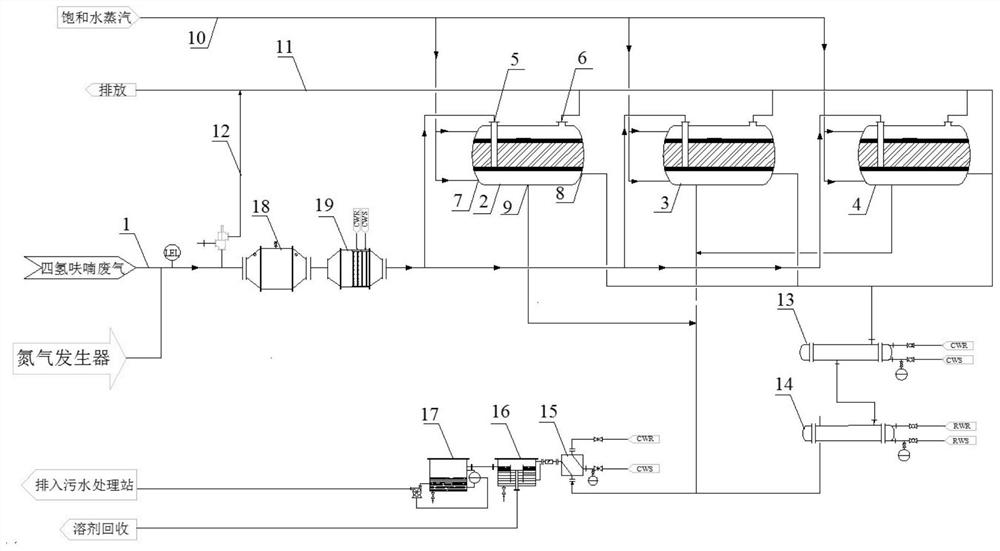

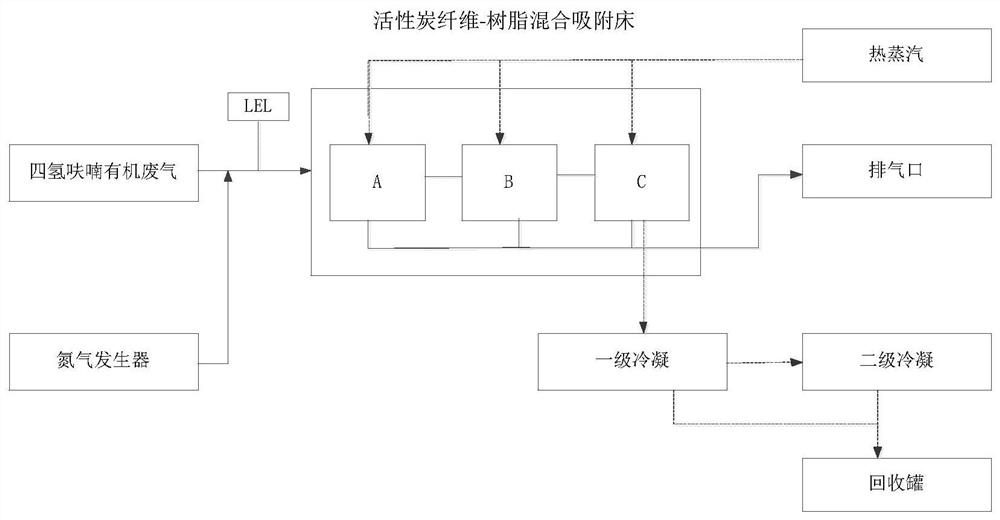

[0034] A high-concentration tetrahydrofuran organic waste gas treatment device, the structure diagram is as follows figure 1 As shown, the device includes a gas delivery device, an adsorption device, an LEL online monitoring device, a desorption device, a vacuum pump and a condensation recovery device; the gas delivery device includes an intake pipe 1, a nitrogen generator, a bypass exhaust pipe 12 and a total exhaust The gas pipeline 11 is provided with a nitrogen generator on the waste gas delivery pipeline to dilute the concentration of tetrahydrofuran in the waste gas to ensure that the inlet concentration is lower than the lower explosion limit, otherwise it will be discharged urgently by the bypass exhaust pipeline 12 and prevent contact with air; 1 along the air intake direction are provided with an exhaust gas filter 18 and an air cooler 19 in order to realize the preliminary filtration and cooling operation of organic waste gas and further improve the efficiency of waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com