Patents

Literature

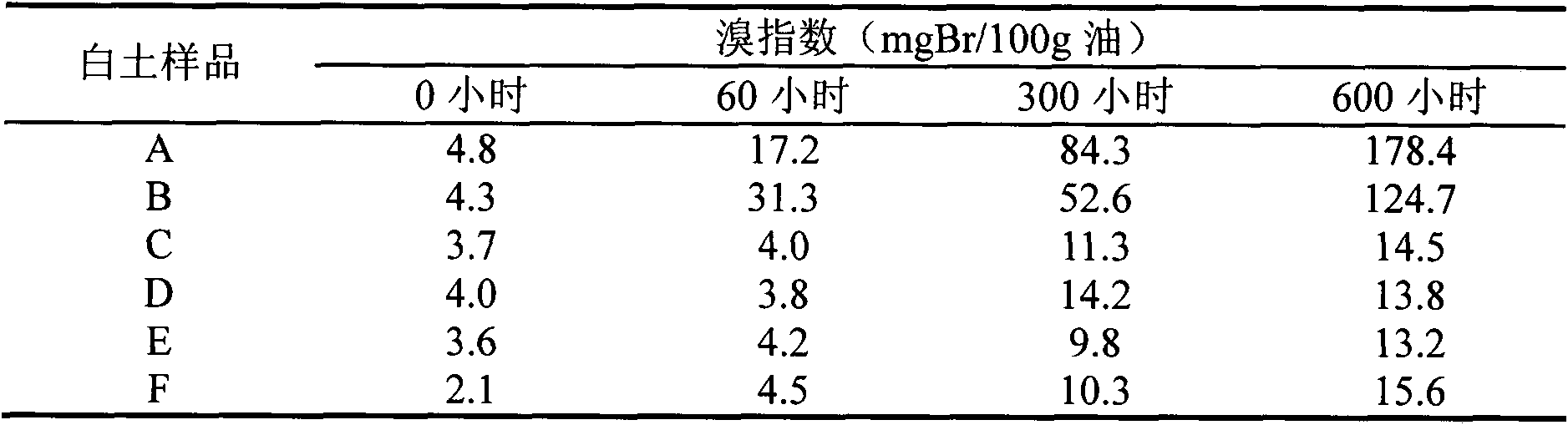

49results about How to "High initial activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

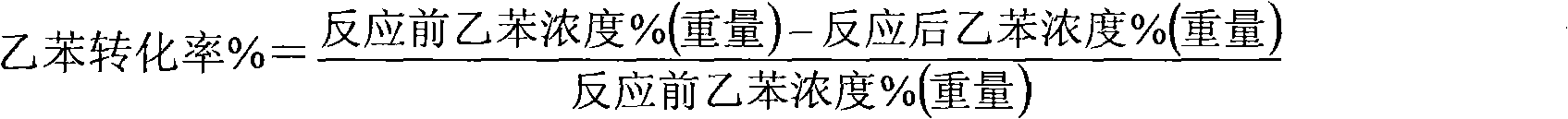

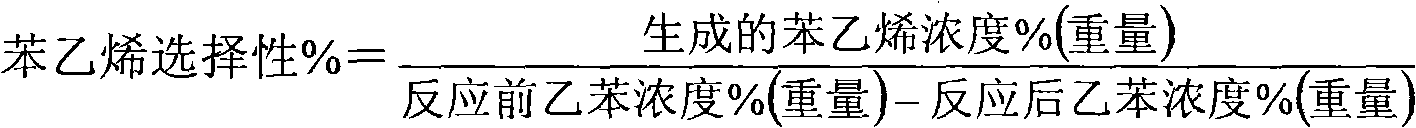

Method for preparing styrene catalyst by ethyl benzene dehydrogenation

ActiveCN102039204AHigh activityHigh initial activityCatalyst activation/preparationHydrocarbonsCeriumDehydrogenation

The invention relates to a method for preparing a styrene catalyst by ethyl benzene dehydrogenation, which mainly solves the problems of low initial activity and long induction period of the catalyst in the prior art. The method comprises the following steps of: mixing a required amount of cerium source, a required amount of iron source, potassium source, molybdenum source or tungsten source and mixture thereof, alkaline earth metal oxide and pore forming agent uniformly, and molding, drying and roasting to obtain a catalyst precursor I; and carrying the rest cerium source on the catalyst precursor I by adopting a dipping method, and drying and roasting to obtain the required catalyst. According to the technical scheme, the problems are well solved, and the method can be used for industrial production of preparing the styrene by ethyl benzene dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

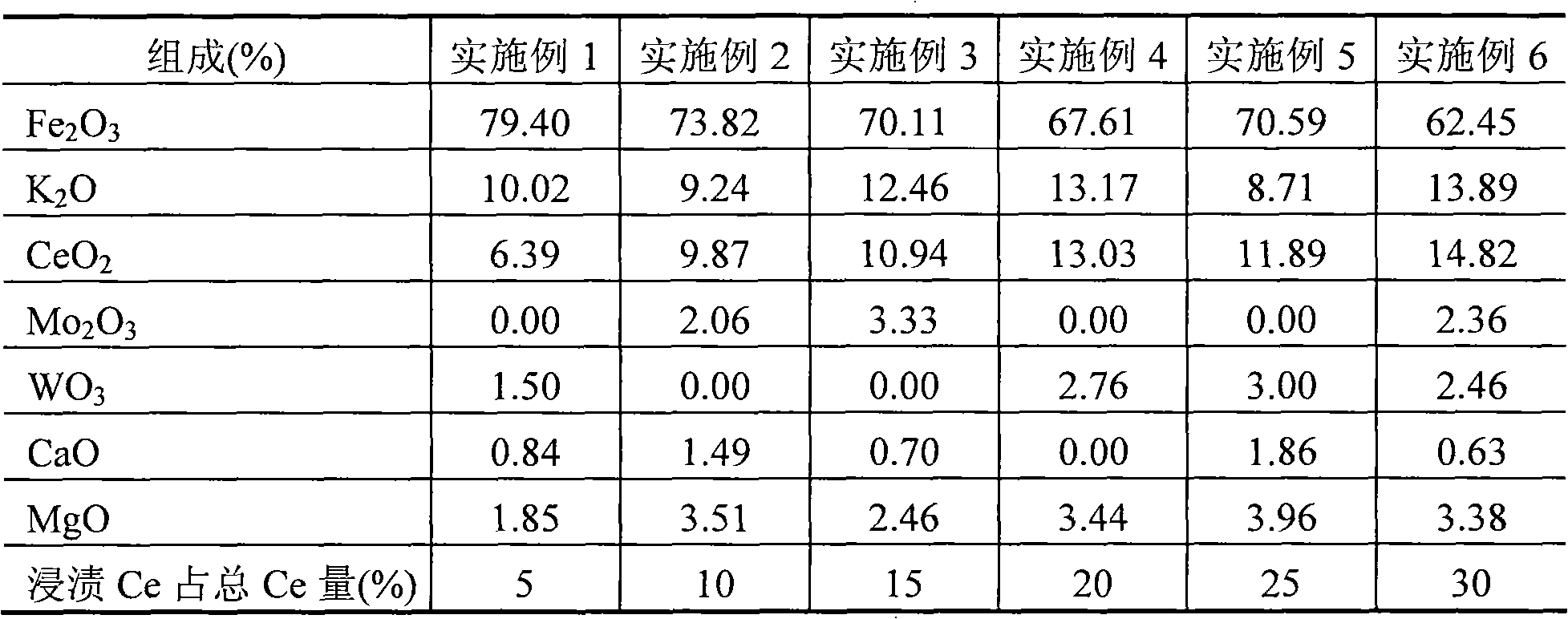

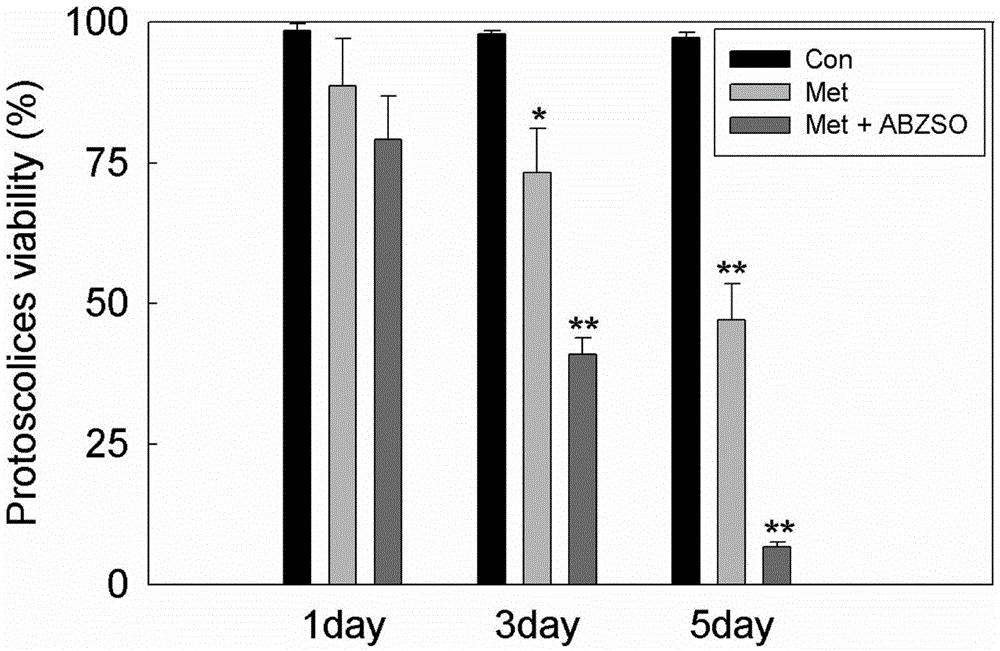

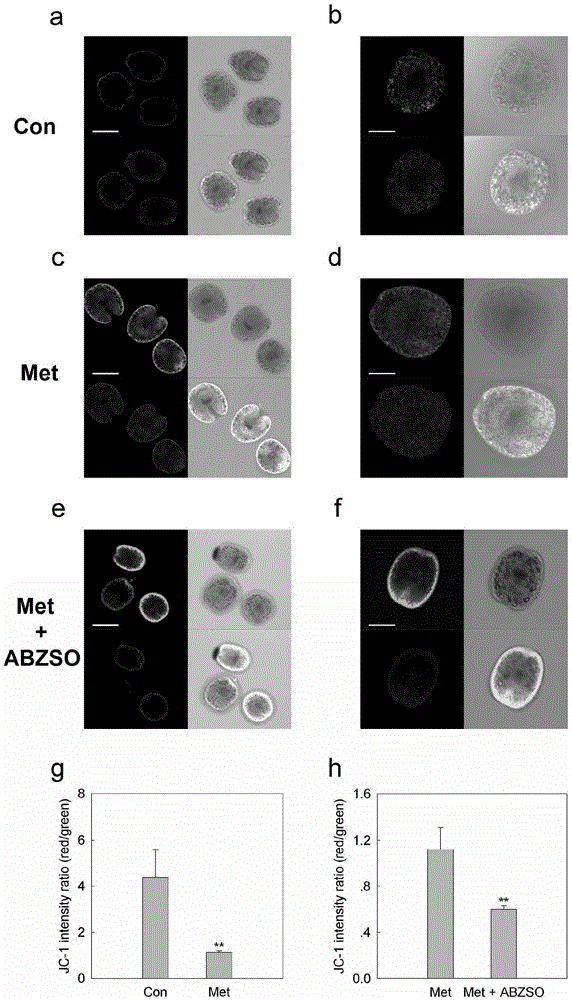

Imaging model in small animal living bodies with echinococcus granulosus and construction method thereof

InactiveCN105641716AHigh incidenceIncreased mortalityCompounds screening/testingLuminescence/biological staining preparationIntraperitoneal routePositive control

The invention discloses an imaging model in small animal living bodies with echinococcus granulosus and a construction method thereof. The construction method comprises the steps of: feeding CF-1 male mice; carrying out in vitro culture and drug treatment on protoscolex; carrying out in vitro fluorescence imaging and fluorescence gradient analysis; pretreating mice with depilatory paste for experimental animals, injecting the abdominal cavity of each mouse with chloral hydrate anesthetic, implanting three groups of stained scoleces under Glisson capsules by injection, dividing the mice into three groups according to different groups of injected protoscolex; in a control group, injecting the livers of mice with protoscolex on which drug treatment is not carried out, collecting images every 12 hours after injection, carrying out fluorescence intensity analysis on the ROIs region, putting into a polyethylene cage after imaging, and carrying out in vitro fluorescence gradient detection in the positive control group. The construction method constructs a mouse model with echinococcus granulosus which can express luciferase, provides a platform for drug sensitive tests in living bodies with echinococcosis, and can monitor the growth and transfer of hydatid in the living model dynamically in a long term.

Owner:王思博

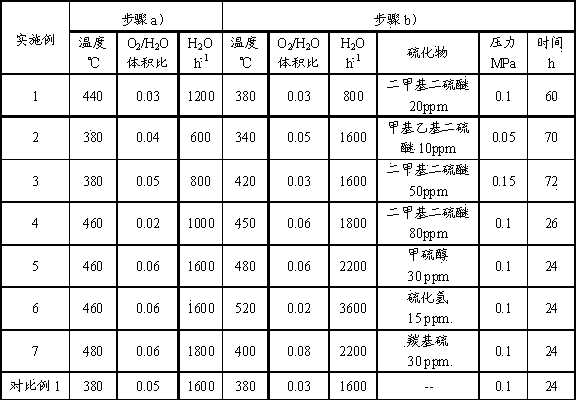

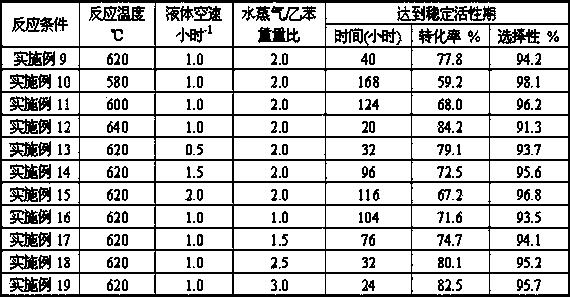

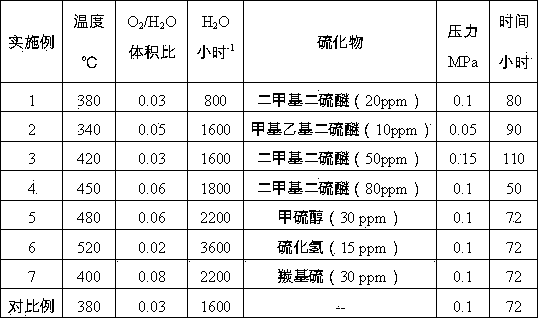

Regeneration method of butene oxidative dehydrogenation catalyst

ActiveCN104226334ARestore activityExtended induction periodCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsBurn treatmentGas phase

The invention relates to a regeneration method of a butene oxidative dehydrogenation catalyst, and mainly solves the problems of poor regeneration effect, decreased activity after regeneration, long induction period and shortened service life of the catalyst in the prior art. The method provided by the invention comprises the following steps: a) conducting carbon burning treatment on inactivated iron spinel composite oxide catalyst for butene oxidative dehydrogenation to produce butadiene at 360-480 DEG C under the conditions of oxygen / steam volume ratio of 0.01-0.06 and water vapor airspeed of 400-2000 / h for 2-24 h; b) treating the catalyst subjected to carbon burning at 300-550 DEG C under the conditions of gauge pressure of 0-0.2 MPa, oxygen / steam volume ratio of 0.01-0.1, water vapor volume space velocity of 400-4000 / h and sulfide gas phase concentration of 0-100 ppm for at least 24 h. The technical scheme well solves the problem, and can be used in industrial production of butadiene from butene oxidative dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

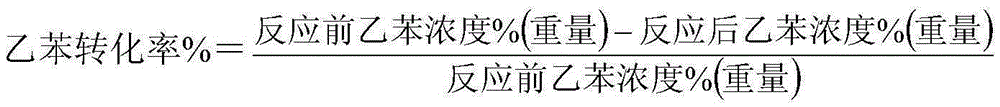

Catalyst for preparing styrene through ethylbenzene dehydrogenation and preparation method of catalyst

ActiveCN103537291AHigh initial activityShort induction periodHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsCeriumDehydrogenation

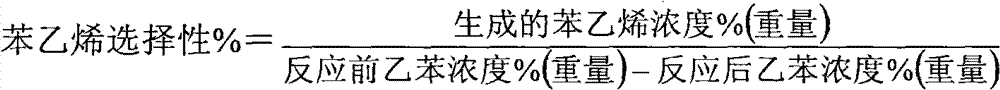

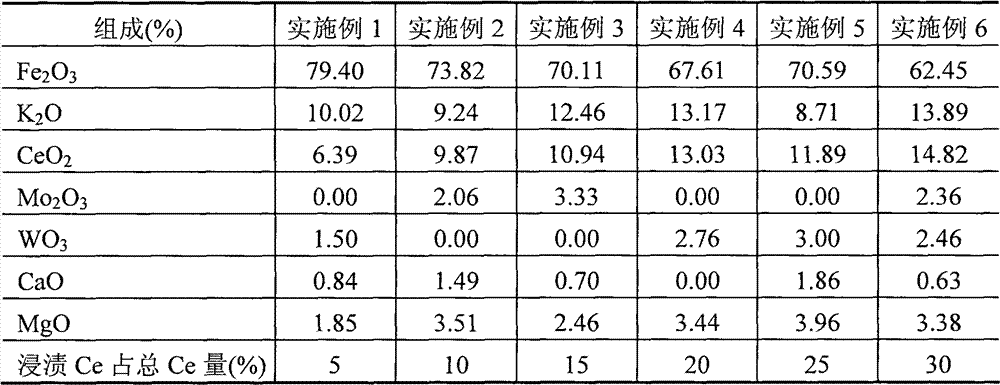

The invention relates to a catalyst for preparing styrene through ethylbenzene dehydrogenation and a preparation method of the catalyst and mainly aims to solve the problems of lower initial activity and longer induction period of the catalyst in the prior art. The technical problems are better solved through the technical scheme that the catalyst and the preparation method thereof are adopted, wherein the catalyst is prepared by adding cerium sources including ammonium ceric nitrate and cerous oxalate as raw materials into a ferrum-potassium-cerium-molybdenum or tungsten catalyst system according to the required proportion. The catalyst can be used for the industrial production of styrene prepared through ethylbenzene dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

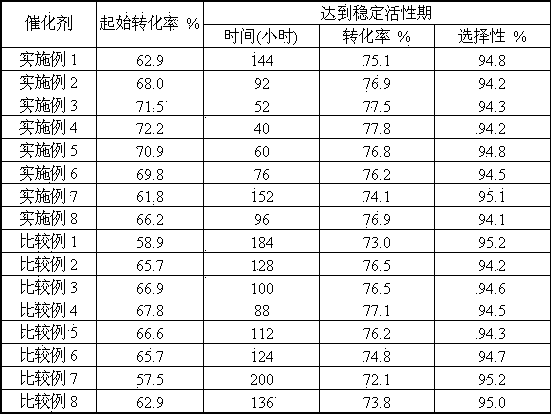

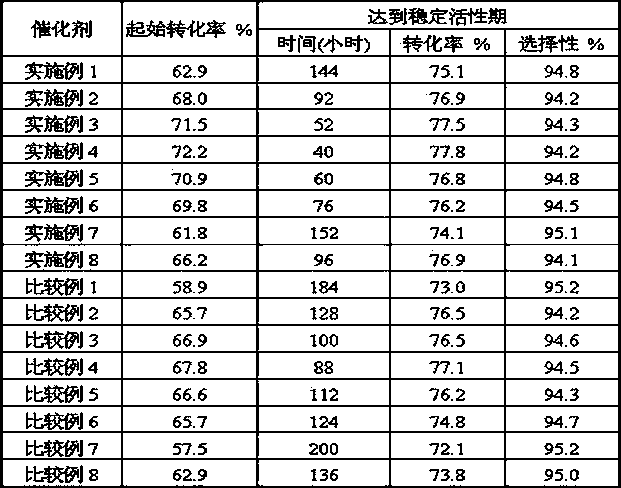

Method for activating ethylbenzene dehydrogenation

InactiveCN101279258AHigh initial activityLower activation temperatureHydrocarbonsChemical recyclingActivation methodState of art

The invention relates to an activation method for ethylbenzene dehydrogenation catalyst, which mainly aims at solving the problems of insufficient activation of the catalyst, long induction period, low initial activity, high initial temperature of the reaction and short service life in the prior art. The invention better solves the problems by the technical scheme that dehydrogenation catalyst is activated for more than 48 hours at the reaction temperature of higher than 600 DEG C, with more than 1.5:1 of weight ratio between water and phenylethane and under the pressure of 70-150kPaA. The method has the advantages of promoting the full formation of an active center, short induction period of the catalyst and high initial activity, which can be used for preparing styrene with ethylbenzene dehydrogenation in industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

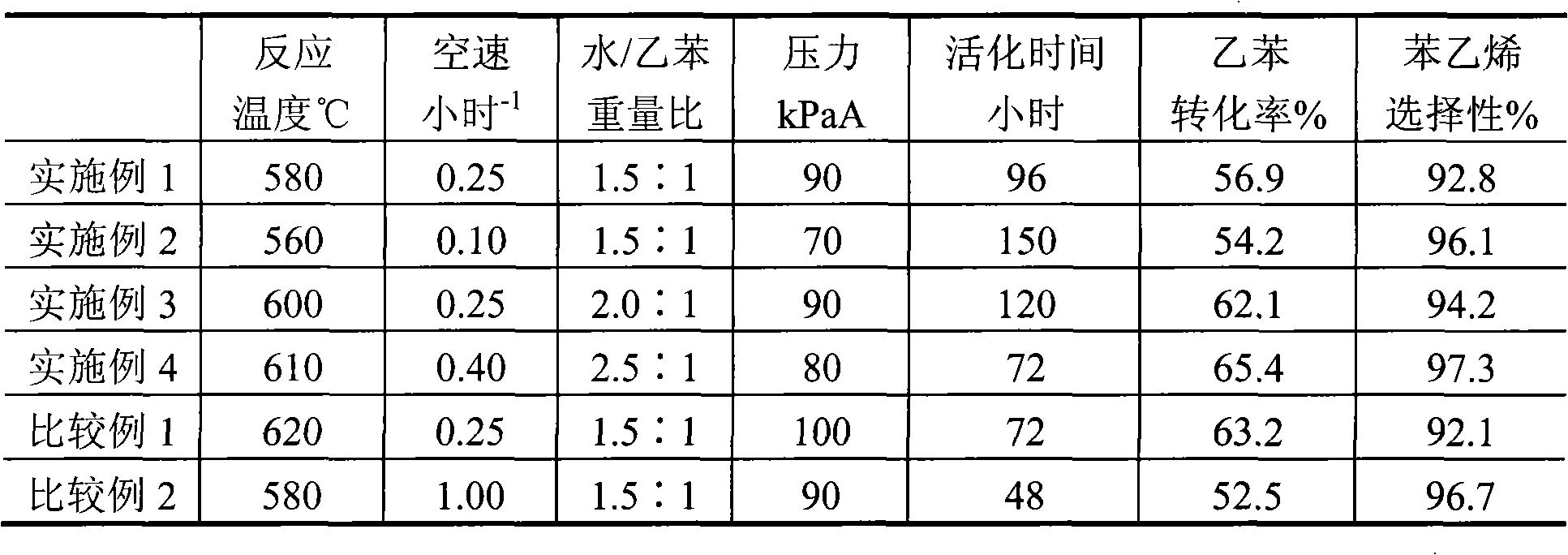

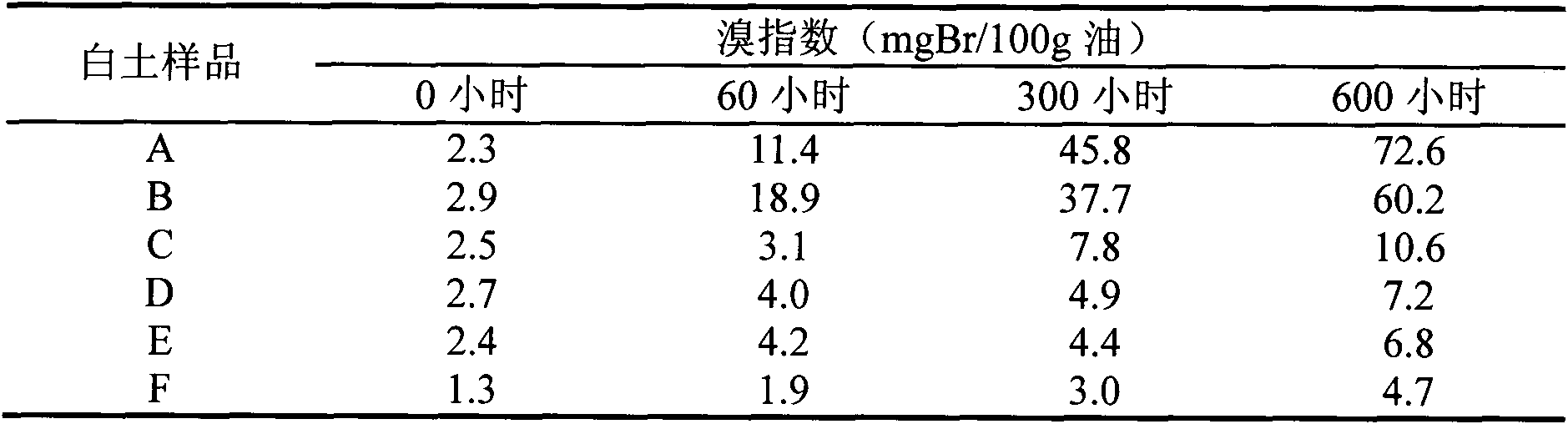

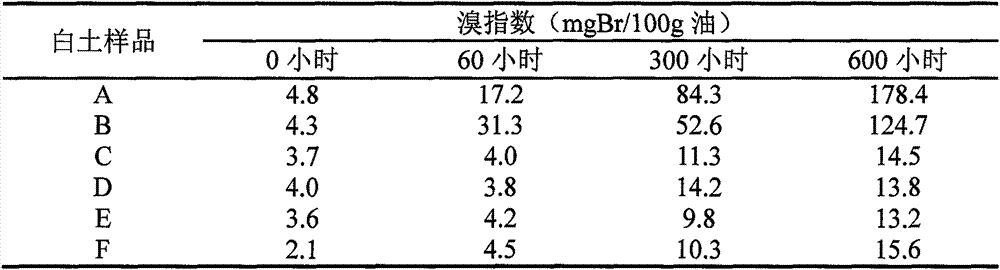

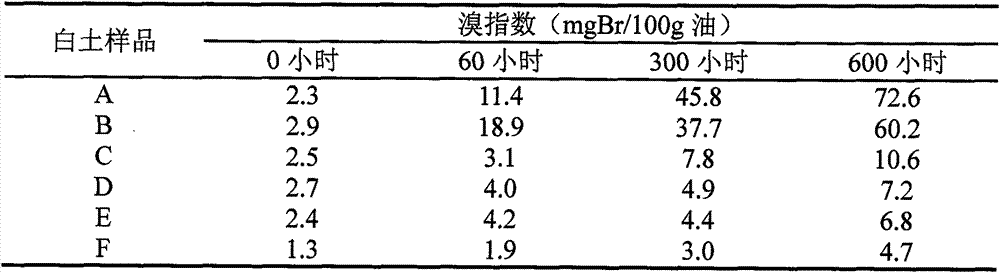

Preparation method and application of ball-type activated clay for removing alkene in aromatic hydrocarbons

InactiveCN103386295AIrregular and easy to drop powderNot easy to hydrolyzeOther chemical processesDispersed particle separationBromineReaction temperature

The invention discloses a preparation method and application of a ball-type activated clay for removing alkene in aromatic hydrocarbons. Compared with common particle white clay, the ball-type activated clay provided by the invention has characteristics of high mechanical strength, high initial alkene removal activity and long running life. Under the reaction temperature of 150-230 DEG C, the ball-type activated clay has initial alkene removal activity no nor than 5.0 mg Br / 100g, bromine index reduced to under 20 Br / 100g and service life of 1-3 years, and has good industrial application prospects.

Owner:安徽力奥环境新材料有限公司

Catalyst for use in producing lower aliphatic carboxylic acid ester, process for producing the catalyst, and process for producing lower aliphatic carboxylic and ester using the catalyst

InactiveUS20030054945A1High initial activityHigh space-time yieldOrganic compound preparationOrganic chemistry methodsAliphatic alcoholBy-product

A catalyst for use in producing a lower aliphatic carboxylic acid ester, which can exhibit high initial activity and high space time yield, ensure a sufficiently long catalyst life in the industrial practice, and reduce the production of by-products; a process for producing the catalyst; and a process for producing a lower aliphatic carboxylic acid ester using the catalyst. The catalyst is produced by a process comprising a step of contacting the catalyst with a gas containing at least one member selected from water, a lower aliphatic carboxylic acid and a lower aliphatic alcohol.

Owner:SHOWA DENKO KK

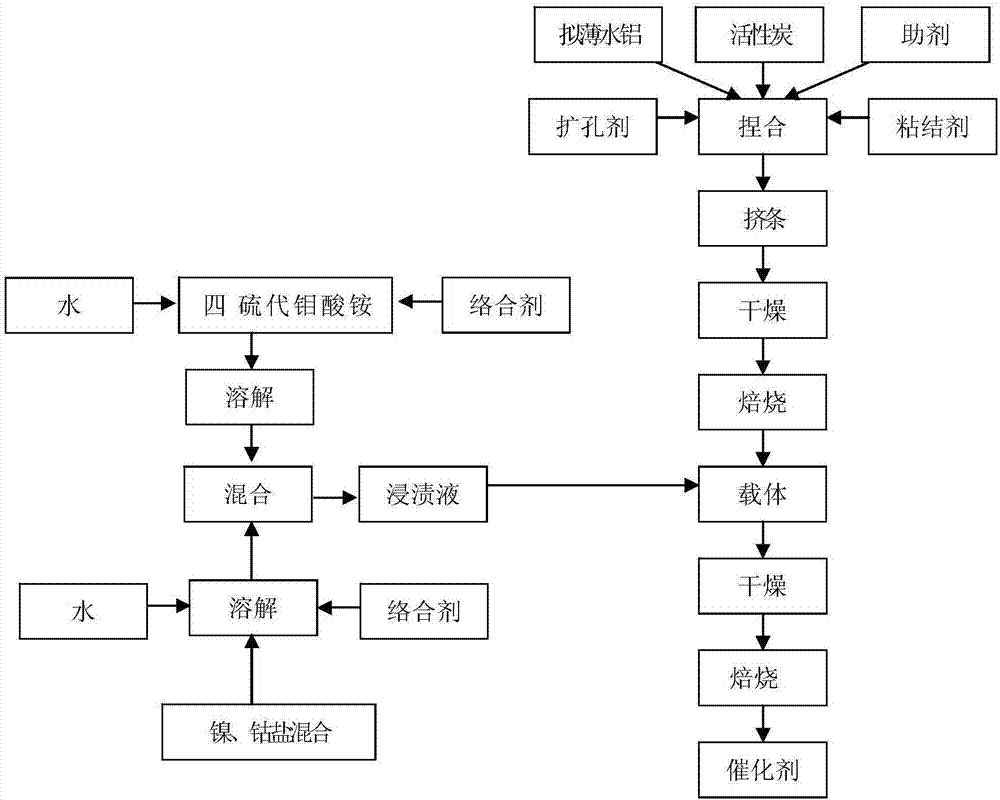

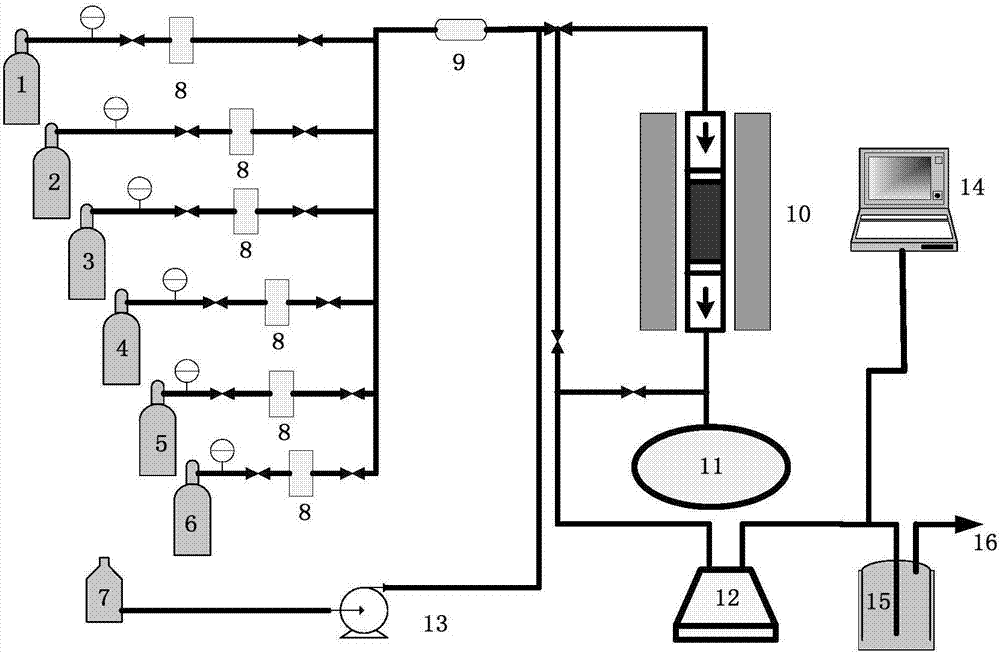

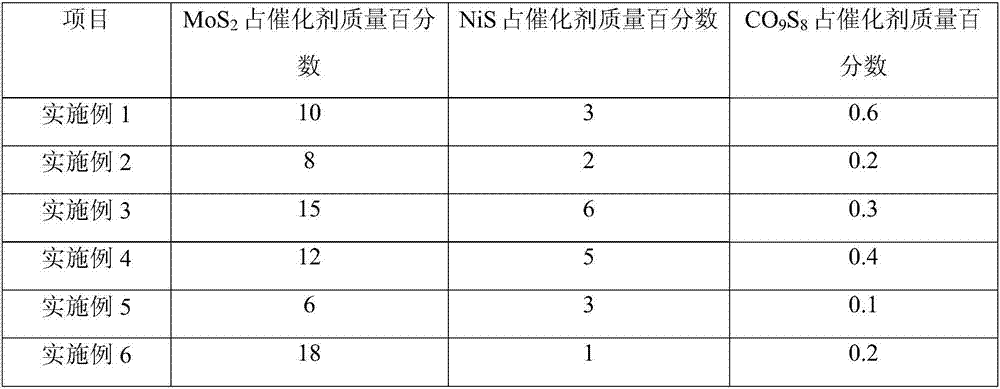

Sulfur tail gas hydrogenation catalyst and preparation method

ActiveCN107469836AHigh initial activityGood stabilityPhysical/chemical process catalystsChemistrySulfide

The invention relates to a novel sulfur tail gas hydrogenation catalyst and a preparation method thereof. Active components in a form of sulfides of the catalyst are supported on a catalyst carrier. The active components are sulfides of cobalt, molybdenum and nickel. The catalyst has the characteristics of no pre-vulcanization, high initial activity and good stability. The catalyst is in a vulcanized state and does not need to be vulcanized in use. Through use of the catalyst, sulfur device problems of environmental protection and safety during pre-vulcanization are avoided, excessive emission of SO2 during sulfur device operation is avoided, green operation is realized and significant economic and social benefits are obtained.

Owner:CHINA PETROLEUM & CHEM CORP

A preparation method and application of spherical activated clay for removing olefins in aromatics

InactiveCN103386295BIrregular and easy to drop powderNot easy to hydrolyzeOther chemical processesDispersed particle separationBromineReaction temperature

The invention discloses a preparation method and application of a ball-type activated clay for removing alkene in aromatic hydrocarbons. Compared with common particle white clay, the ball-type activated clay provided by the invention has characteristics of high mechanical strength, high initial alkene removal activity and long running life. Under the reaction temperature of 150-230 DEG C, the ball-type activated clay has initial alkene removal activity no nor than 5.0 mg Br / 100g, bromine index reduced to under 20 Br / 100g and service life of 1-3 years, and has good industrial application prospects.

Owner:安徽力奥环境新材料有限公司

Method for the reductive activation of dehydrogenation catalyst by using gas mixture of hydrocarbon/hydrogen

ActiveCN102909099AHigh degree of reductionHigh initial activityCatalyst activation/preparationHydrocarbonsAlkanePtru catalyst

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of Pd-Cu/modified attapulgite clay catalyst

InactiveCN103464170BHigh initial activityImprove stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureCatalytic oxidation

The invention provides a preparation method of a Pd-Cu / modified attapulgite clay catalyst, which comprises the steps of preparing a dispersant solution, and adding attapulgite clay; stirring and performing ultrasonic treatment on the formed suspension; standing and performing heat treatment on the upper-layer suspension; centrifuging and drying to obtain a modified carrier; preparing an aqueous solution of copper salt, palladium salt and urea, and impregnating the modified carrier; slowly drying and quickly roasting to obtain a finished product of the catalyst. The catalyst has high initial activity, good stability and relatively wide range of application conditions, and can perform effective catalytic oxidation of CO under the reaction conditions of reaction temperature of (-50)-100 DEG C, air speed of 2,500-10,000 / h, CO content of 10-10,000ppm and relative humidity of feed gas of 20-100%, and the deactivated catalyst can be regenerated. The preparation method of the catalyst provided by the invention has the advantages of simple process, easiness in operation, low cost and good application prospect.

Owner:SHANXI UNIV

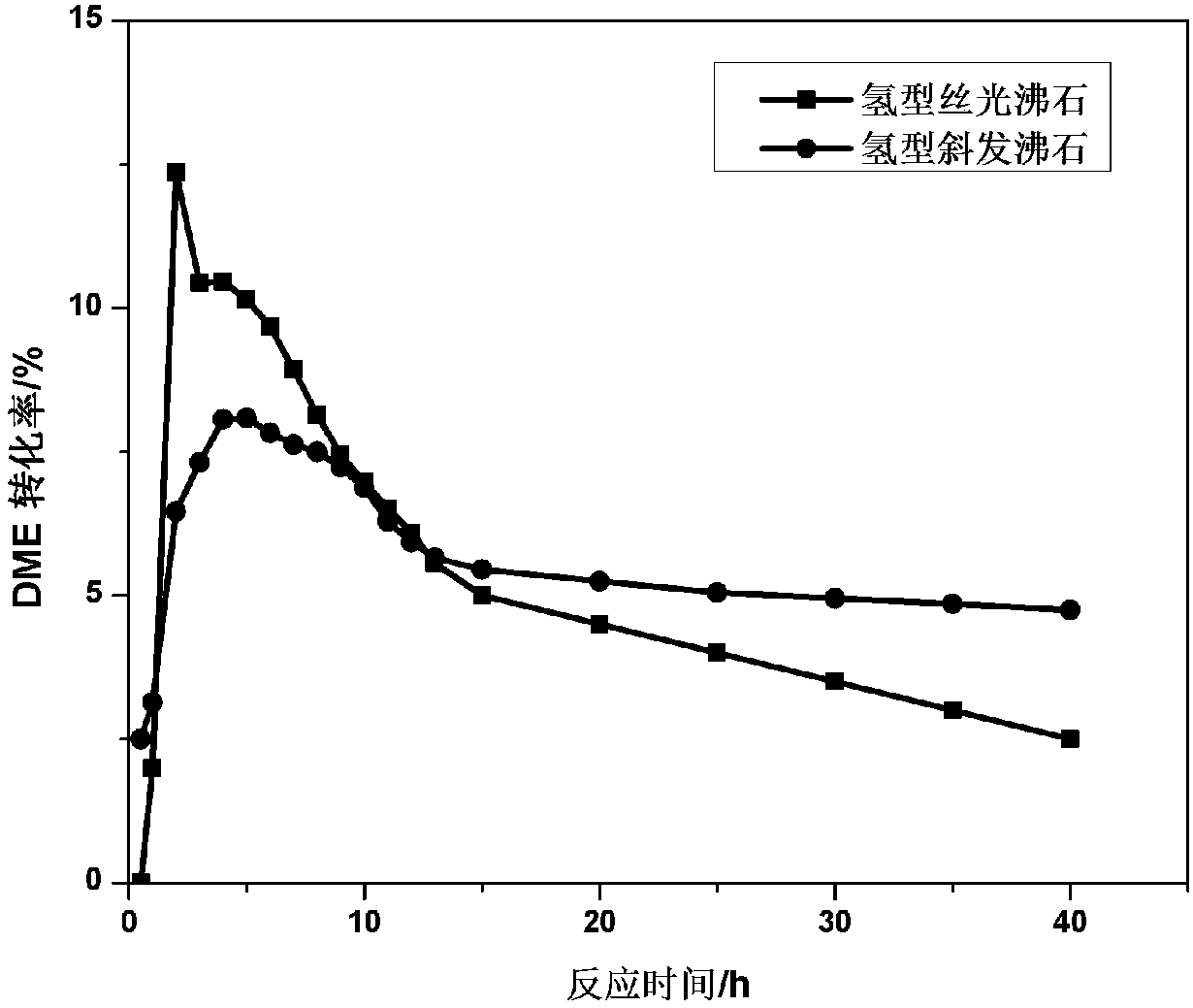

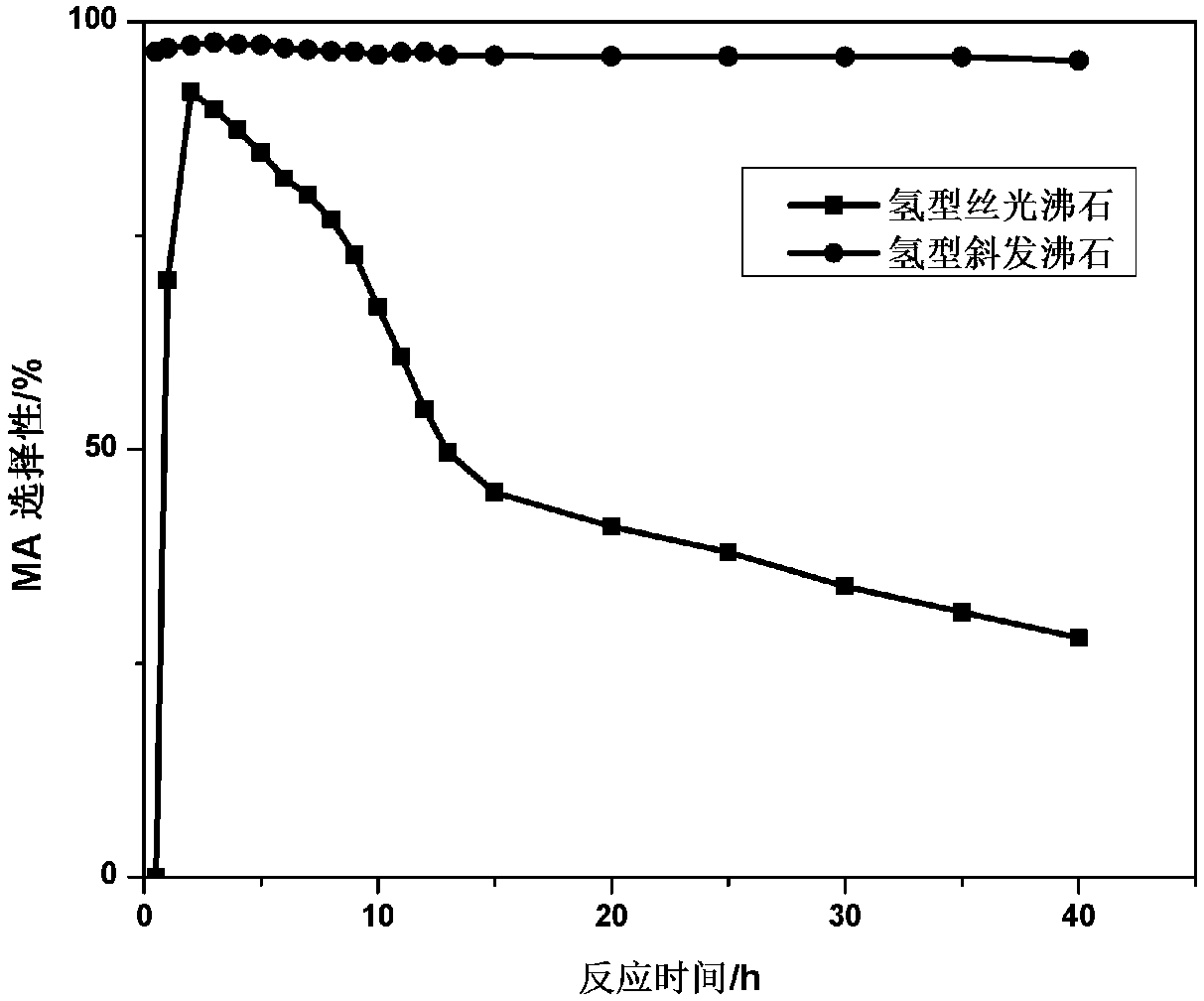

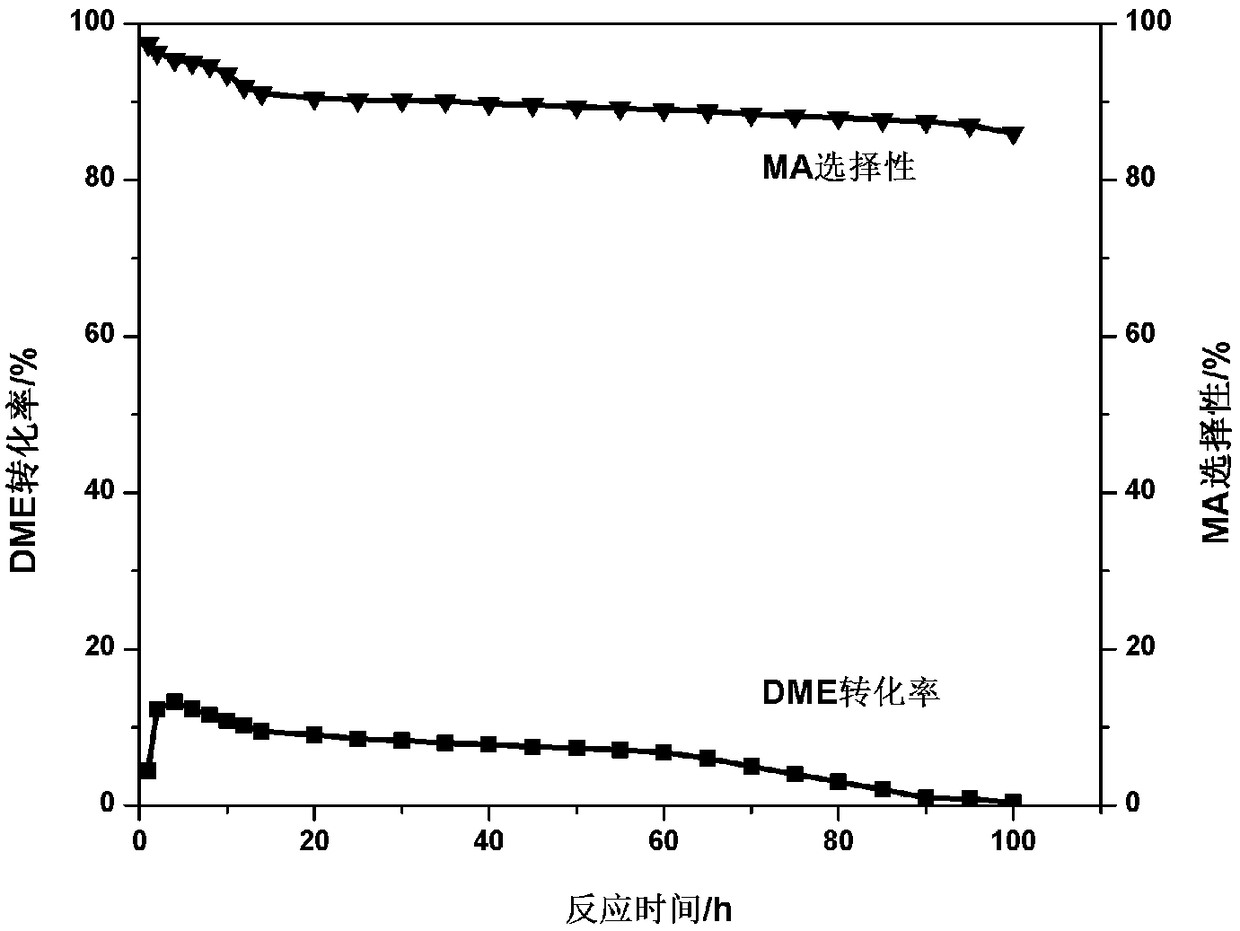

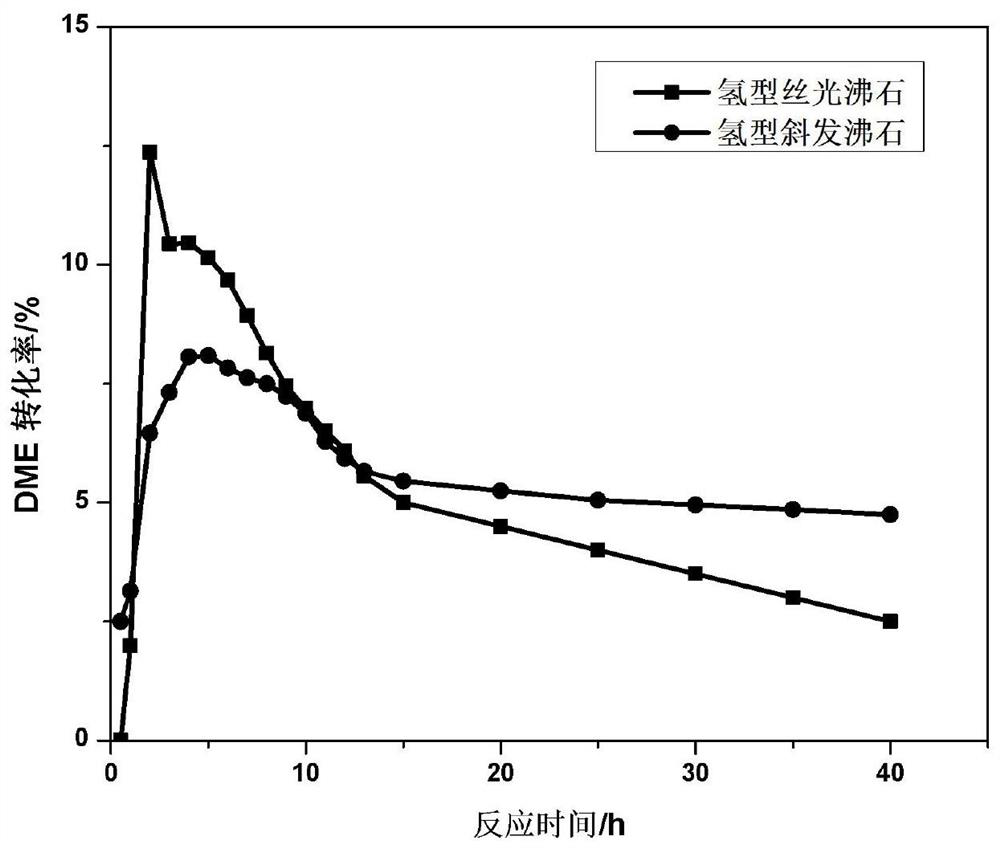

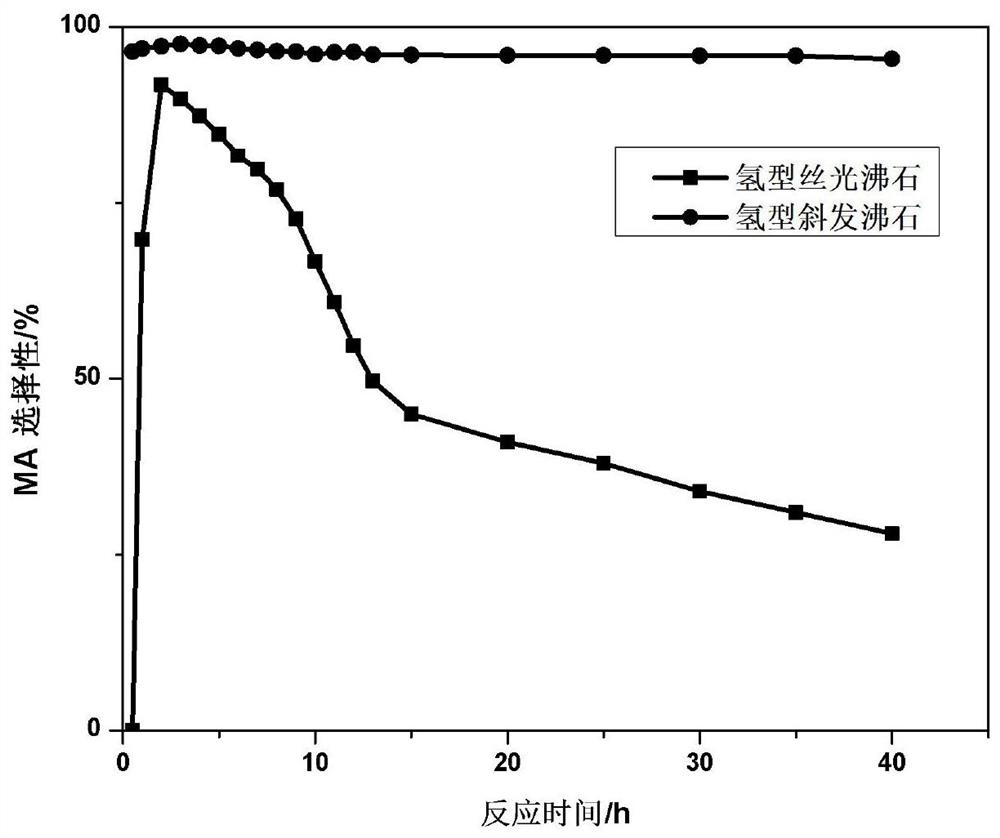

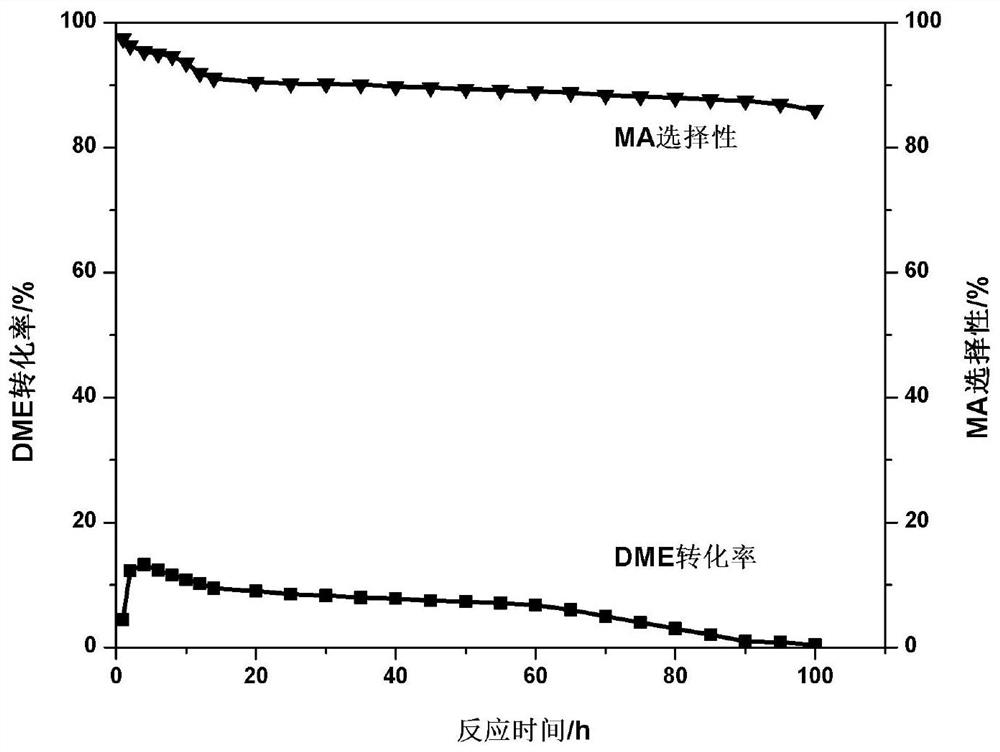

Method for preparing methyl acetate by carbonylation of dimethyl ether

ActiveCN108586247AImprove continuityAchieve stabilityMolecular sieve catalystsCatalyst activation/preparationHydrogenMethyl acetate

The invention provides a method for preparing methyl acetate by carbonylation of dimethyl ether. The method comprises the following steps: subjecting a mixed gas of dimethyl ether and carbon monoxideto carry out a dimethyl ether carbonylation reaction through activated hydrogen-type clinoptilolite to obtain methyl acetate, wherein the hydrogen-type clinoptilolite has an HEU topological structure.The method provided by the invention adopts the hydrogen-type clinoptilolite having the HEU topological structure as a catalyst, the catalyst has an 8-element pore structure, and silicon-aluminum isrelatively low, and can maintain relatively high activity for a long time in the dimethyl ether carbonylation reaction process, thereby realizing the continuity and stability of methyl acetate prepared by carbonylation of dimethyl ether, and also ensuring that methyl acetate has relatively high initial activity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI +2

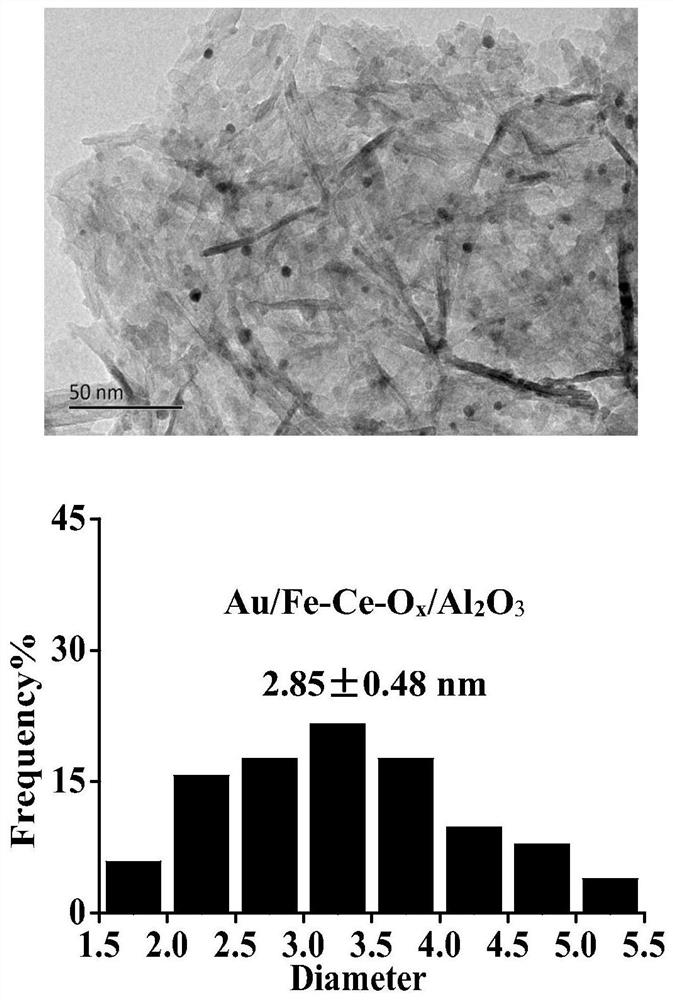

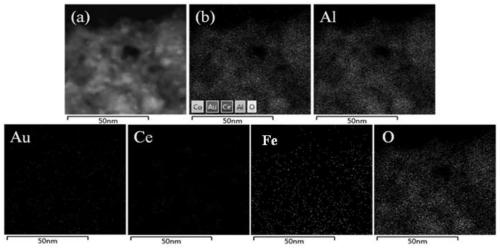

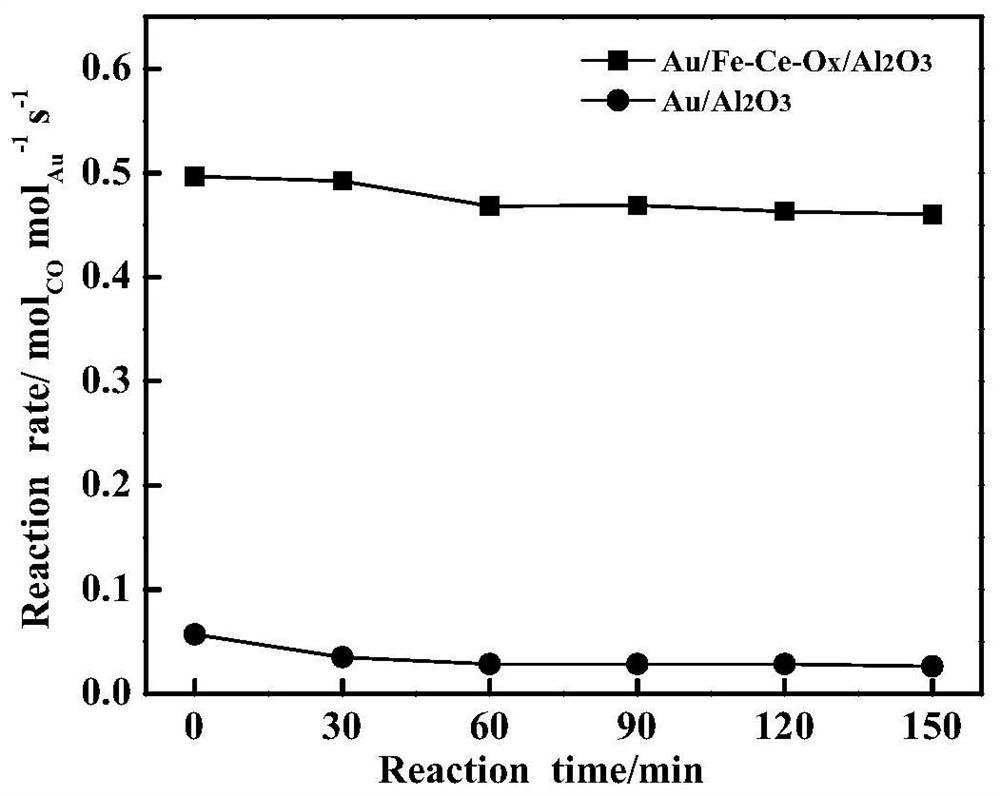

Au/M1-M2-Ox/Al2O3 nano-gold catalyst for catalyzing oxidation of CO in CO2-rich atmosphere

PendingCN111617776AIncreased resistance to carbonate buildupImprove catalytic activity and reaction stabilityCarbon compoundsHeterogenous catalyst chemical elementsActivated oxygenMaterials science

The invention relates to an Au / M1-M2-Ox / Al2O3 nano-gold catalyst for catalyzing oxidation of CO in a CO2-rich atmosphere and a preparation method of the Au / M1-M2-Ox / Al2O3 nano-gold catalyst. Accordingto the preparation method disclosed by the invention, an Al2O3 carrier is modified by a method of adding M1Ox and M2Ox, and the prepared M1-M2-Ox / Al2O3 carrier has fewer strong base sites and is richin active oxygen species, so the Au / M1-M2-Ox / Al2O3 catalyst is prepared. Testing is conducted in an atmosphere of CO2 with a concentration of 60 vol.% to evaluate the activity and stability of the catalyst. Experimental results show that the catalyst provided by the invention has high CO catalytic oxidation activity in the CO2-rich atmosphere, has excellent CO2 accumulation resistance and excellent reaction stability, and has good application potential in CO2-rich scenes such as CO2 lasers.

Owner:YANTAI UNIV

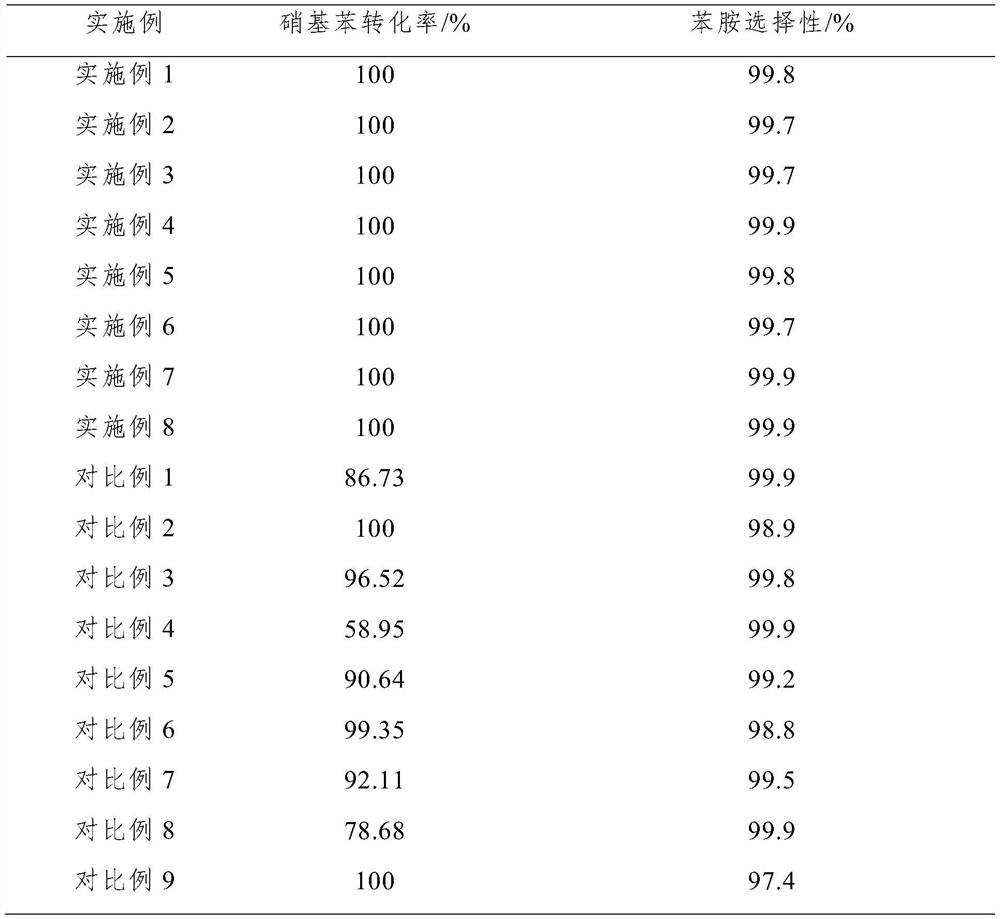

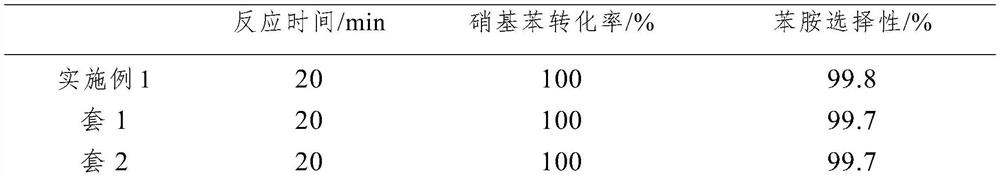

Catalyst for synthesizing aniline through nitrobenzene liquid phase hydrogenation and preparation method thereof

PendingCN112108139AHigh activityExtended service lifeCatalyst carriersOrganic compound preparationSide productNitrobenzene

The invention discloses a catalyst for synthesizing aniline through nitrobenzene liquid phase hydrogenation. The catalyst raw material comprises surface-modified carbon nanotubes and precursor atomized particles containing an active component and auxiliary agents, the active component is Pt, the auxiliary agents are more than two of Ru, Ni, Cr, La and W, and the mass of each assistant is 0.05-1.0%of the mass of the catalyst. In addition, the invention also provides a method for preparing the catalyst. Raw materials of the catalyst comprise surface-modified carbon nanotubes and precursor atomized particles containing the active component and the auxiliary agents, the active component is Pt, and the auxiliary agents are more than two of Ru, Ni, Cr, La and W. The catalyst is applied to catalytic nitrobenzene liquid phase hydrogenation aniline synthesis reaction, and has the advantages of high initial activity, long service life, few tar byproducts, and easy industrial popularization.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

Work starting method for slurry bed Fisher-Tropsch synthesis

ActiveCN102863982AHigh initial activityReduce initial activityLiquid hydrocarbon mixture productionHydrogenWater vapor

The invention relates to a work starting method for slurry bed Fisher-Tropsch synthesis, which is characterized in that a proper amount of a reduced ft synthesis catalyst and a reaction solvent are weighted and placed in a slurry bed reactor, after airtight and gas displacement, the hydrogen mixed gas containing water vapor or organic matter steam containing oxygen is introduced and a stirring device is switched on, the volume concentration of water vapor or oxygen-containing organic matter steam is 1-5%, the volume space velocity of the gas mixture is 500-2000h<-1>, the temperature is heated to 250-350 DEG C, the pressure is controlled at 2.5-3.5 MPa, the temperature and the pressure can be reduced after 1-3 hours to reach the Fisher-Tropsch synthesis reaction condition, and the synthesis gas is switched for Fisher-Tropsch synthesis reaction. The work starting method is used for keeping the high activity during the stable period of a cobalt-based Fischer-Tropasch synthetic catalyst, and reducing the initial activity of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

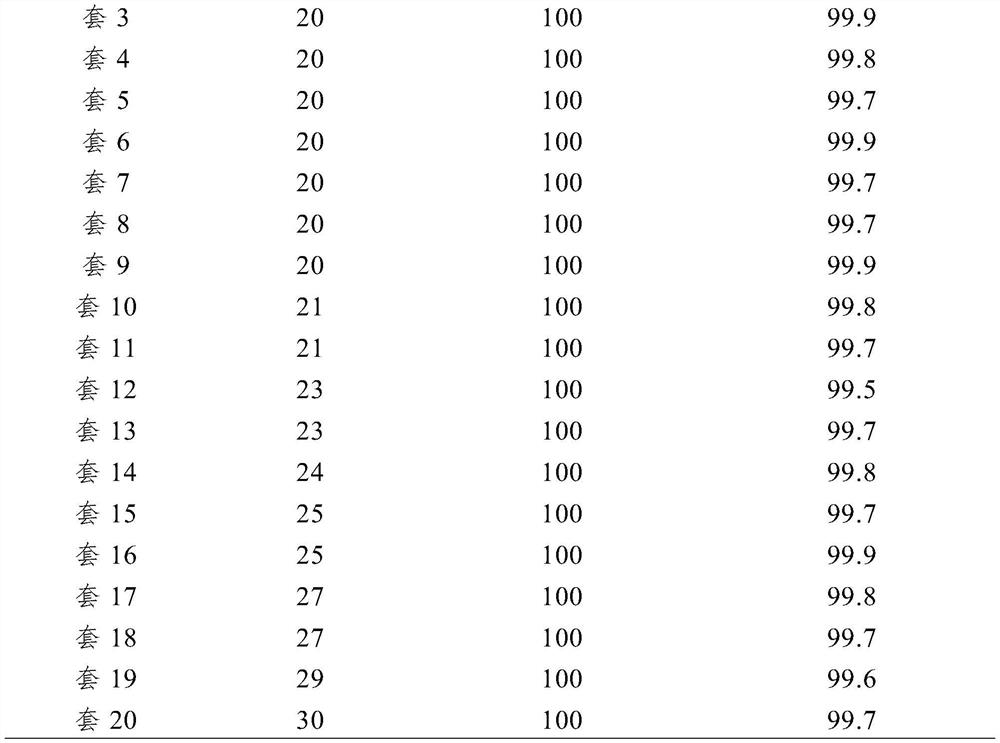

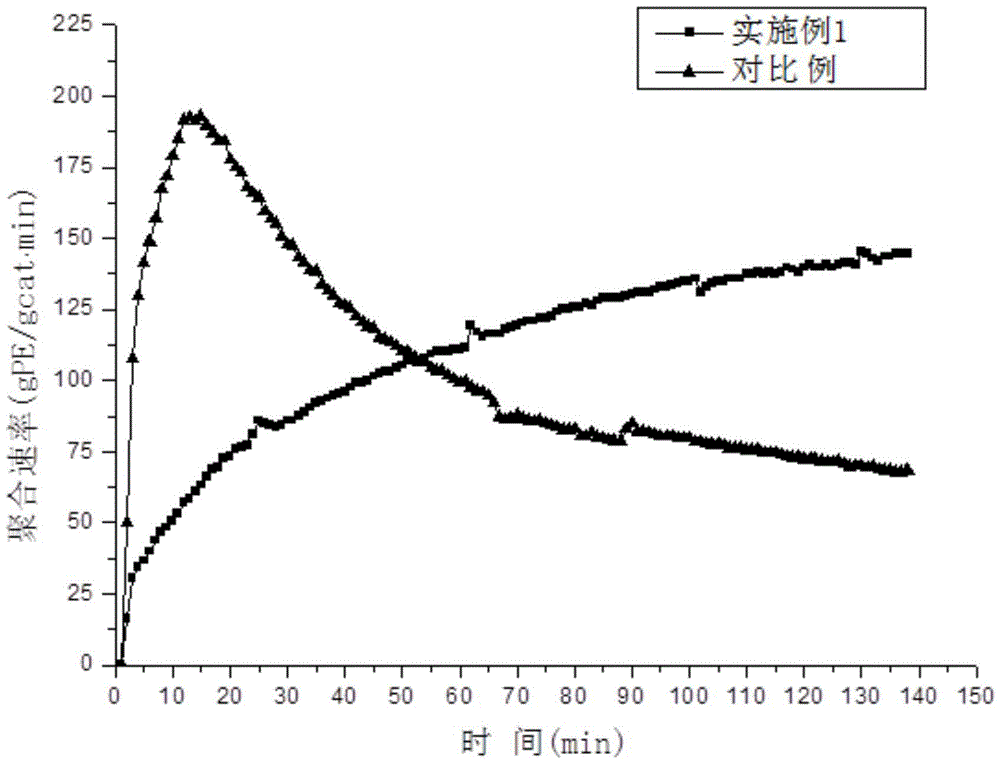

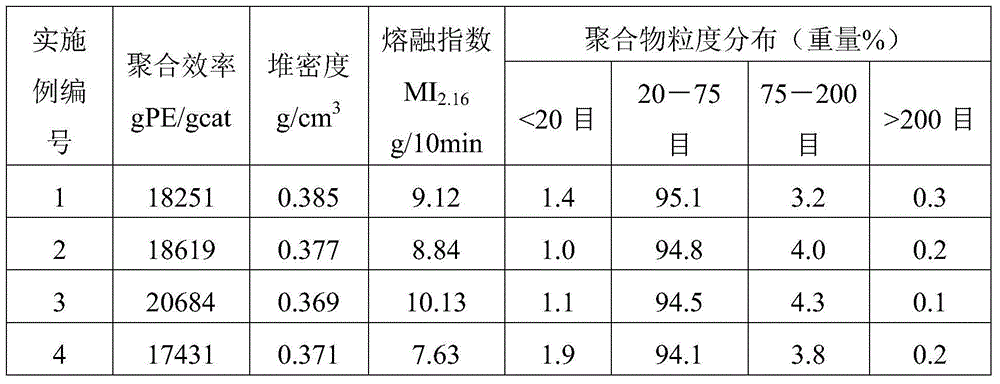

Vinyl polymerization catalyst and preparing method thereof

The invention relates to vinyl polymerization catalyst and a preparing method thereof. A dialkyl magnesium compound, an aluminum alkyl compound, an alcohol compound and an organic epoxy compound reach with one another through the catalyst to obtain a magnesium compound solution, then titanium compound reacts with the magnesium compound solution, the obtained solution reacts with alph-olefin, solid particles containing prepolymer are obtained, the solid particles react with linear-chain halogenated alkane, and the final catalyst is obtained. Compared with the prior art, the catalyst is high in polymerization activity, stable in reaction, sensitive in hydrogen regulation and high in stacking density, the obtained polymer grains are narrowly distributed, and the number of fine powder is small.

Owner:SHANGHAI RES INST OF CHEM IND +1

Method for preparing styrene employing ethylbenzene dehydrogenation

InactiveCN103664496AHigh initial activityShort initial activityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsPotassiumDehydrogenation

The invention relates to a method for preparing styrene employing ethylbenzene dehydrogenation, and mainly solves the problems of low initial activity and long induction period of a catalyst in the prior art. The method adopts the technical scheme as follows: a cerium source adopts ceric ammonium nitrate and cerous oxalate as raw materials and then the raw materials are added to the catalyst according to the required ratio in an iron-potassium-cerium-molybdenum or tungsten catalyst system, and meanwhile, the catalyst obtained from a cerium active component by adopting a mode of leading to the catalyst employing a sub-step method is applied to preparation of styrene employing ethylbenzene dehydrogenation, so that the problem is well solved, and the method can be applied to industrial production of styrene preparation employing ethylbenzene dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for start-up and operation of a fischer-tropsch reactor

ActiveUS20170081593A1High initial activityEasy to startHydrocarbon from carbon oxidesCatalyst activation/preparationFixed bedReaction temperature

The invention relates to a method for start-up and operation of a Fischer-Tropsch reactor comprising the steps of: (a) providing a reactor with a fixed bed of reduced Fischer-Tropsch catalyst that comprises cobalt as catalytically active metal; (b) supplying a gaseous feed stream comprising carbon monoxide and hydrogen to the reactor, wherein the gaseous feed stream initially comprises a nitrogen-containing compound other than molecular nitrogen in an initial concentration in the range of from 0.1 to 50 ppmv based on the volume of the gaseous feed stream; (c) converting carbon monoxide and hydrogen supplied with the gaseous feed stream to the reactor into hydrocarbons at an initial reaction temperature, wherein the initial reaction temperature is set at a value of at least 200° C. and hydrocarbons are produced at a first yield; (d) maintaining the initial reaction temperature at the set value and maintaining the first yield by decreasing the concentration of the nitrogen-containing compound in the gaseous feed stream supplied to the reactor; (e) optionally increasing the reaction temperature after the concentration of the nitrogen-containing compound in the gaseous feed stream has decreased to a value below 100 ppbv.

Owner:SHELL USA INC

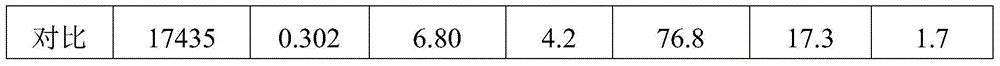

Activation method of butene oxidative dehydrogenation catalyst

ActiveCN104226376AReduced service lifeHigh initial activityCatalyst activation/preparationHydrocarbonsButadiene DioxidePtru catalyst

The invention relates to an activation method of a butene oxidative dehydrogenation catalyst, and mainly solves the problems of long induction period, low initial activity and shortened service life in the prior art of butadiene production. The method provided by the invention comprises the following steps: treating the iron series spinel composite oxide catalyst for butylene oxidative dehydrogenation to produce butadiene at 300-550 DEG C under the conditions of gauge pressure of 0-0.2 MPa, oxygen / steam volume ratio of 0.01-0.1, water vapor volume space velocity of 400-4000 / h and sulfide gas phase concentration of 0-100 ppm for at least 24 h. The technical scheme well solves the problem, and can be used in industrial production of butadiene from butene oxidative dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

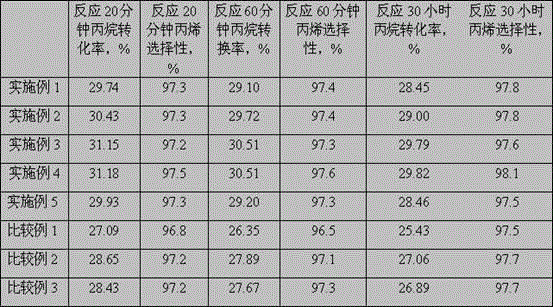

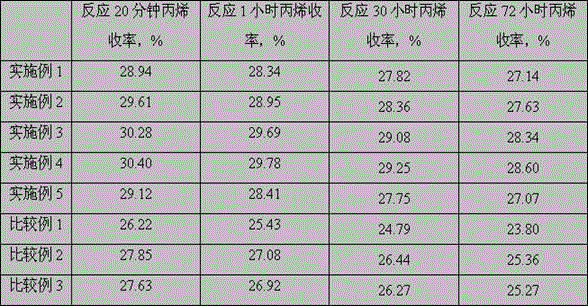

Modified Co-based catalyst and preparation method and application thereof, and method for preparing propylene through anaerobic dehydrogenation of propane

ActiveCN113318774AHigh activityImprove catalytic performanceMolecular sieve catalystsMolecular sieve catalystPtru catalystDehydrogenation

The invention provides a modified Co-based catalyst and a preparation method and application thereof, and a method for preparing propylene through anaerobic dehydrogenation of propane. The modified Co-based catalyst provided by the invention comprises a carrier Silicalite-1, an active component and an auxiliary agent, wherein the active component and the auxiliary agent are loaded on the carrier; the active component is metal Co and / or an oxide of the metal Co; the auxiliary agent is metal M and / or oxide of the metal M; the metal M is one or more selected from Mg, Zr, Nd, W, La, Ce and Zn. The modified Co-based catalyst is used as a catalyst for preparing propylene through anaerobic dehydrogenation of propane, so side reactions can be effectively avoided, olefin selectivity is improved, the reaction performance of the catalyst for catalyzing anaerobic dehydrogenation of propane is improved, and efficient conversion of propane into propylene is realized; and the regeneration stability of the catalyst is also improved, and high initial activity can still be kept after three times of regeneration.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

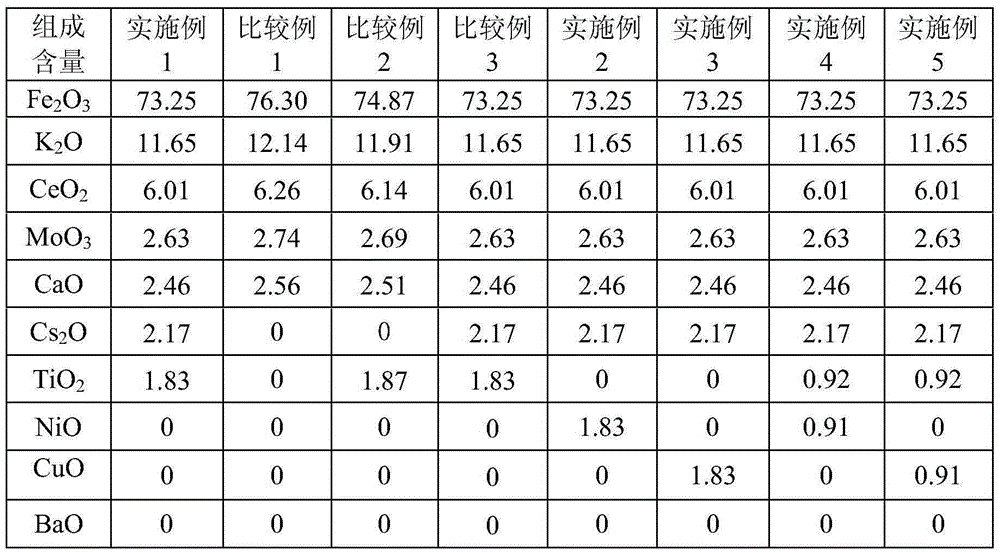

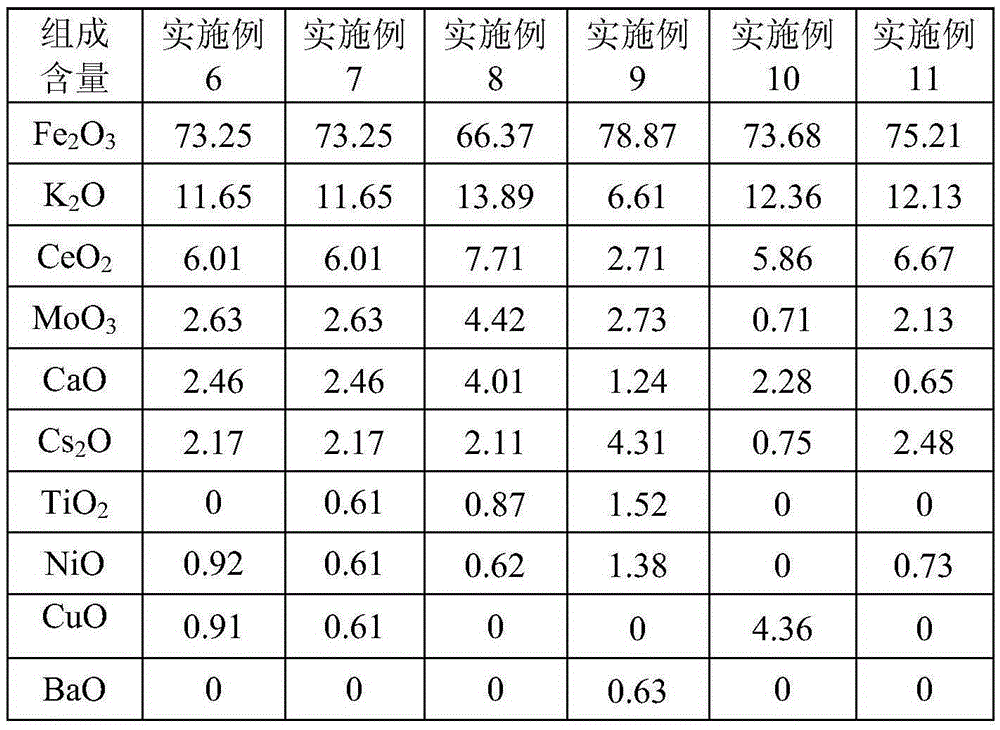

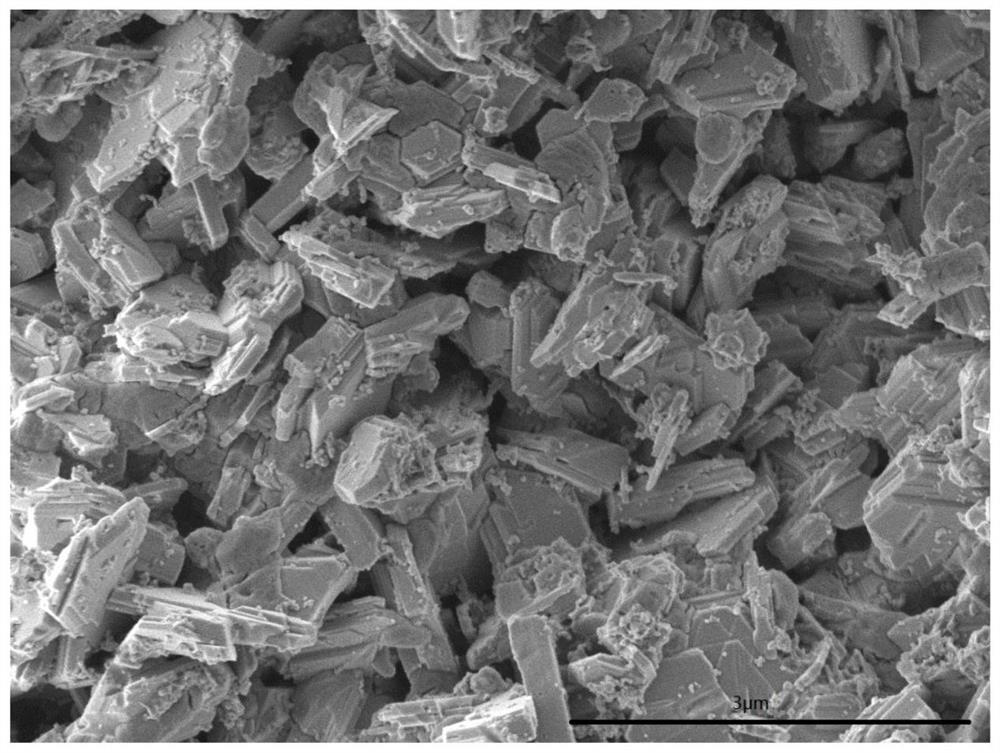

Catalyst for preparation of styrene

ActiveCN106582675AHigh initial activityExtended induction periodHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsCeriumRare earth

The invention relates to a catalyst for preparation of styrene and a preparation method of the catalyst and mainly solves the problems that a low-cerium catalyst has lower initial activity and a long induction period in the prior art. The low-rare-earth catalyst for preparation of styrene is prepared from the following components in percentage by weight: 66%-79% of Fe2O3, 6%-14% of K2O, 2%-7.8% of CeO2, 0.6%-4.5% of MoO3, 0.6%-4.5% of CaO, 0.6%-4.5% of Cs2O and 0.6%-4.5% of one or several of TiO2, NiO and CuO. The problems are better solved, and the catalyst can be used for industrial production of styrene through ethylbenzene dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Iron-based catalyst, preparation method and application thereof

ActiveCN112657503AHigh initial activityImprove technical effectHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention relates to an iron-based catalyst, a preparation method and application thereof, and mainly solves the technical problem that the initial activity is not high enough when alkyl aromatic hydrocarbon is dehydrogenated to generate alkenyl aromatic hydrocarbon in the prior art. According to the technical scheme, the iron-based catalyst comprises iron, potassium, rare earth metal R and other metal additive components, and satisfies the following formulas that (Fe / R) XRF=3.5-11 and (Fe / R)EDS / (Fe / R)XRF = 0.7-1.1, wherein (Fe / R)XRF is the weight ratio of the iron component to the rare earth metal component in the catalyst represented by an X-ray fluorescence spectrum in terms of elements, and (Fe / R)EDS is the weight ratio of the iron component to the rare earth metal component in the surface of the catalyst, which is characterized by an X-ray energy spectrum instrument, in terms of elements. According to the technical scheme, the technical problem is better solved, and the iron-based catalyst can be used for industrial production of alkenyl arene generated by dehydrogenation of alkyl arene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing cobalt-based Fischer-Tropsch synthetic catalyst

ActiveCN102441403BHigh initial activityReduce initial activityCatalyst activation/preparationLiquid hydrocarbon mixture productionActive componentWater vapor

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing styrene catalyst by ethyl benzene dehydrogenation

ActiveCN102039204BHigh activityHigh initial activityCatalyst activation/preparationHydrocarbonsCeriumDehydrogenation

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for use in producing lower aliphatic carboxylic acid ester, process for producing catalyst and process for producing lower alphatic carboxylic acid ester using the catalyst

InactiveCN1446189AHigh initial activityHigh space-time yieldPhysical/chemical process catalystsOrganic compound preparationAliphatic alcoholProduct gas

This article relates to a catalyst for producing a lower aliphatic carboxylic acid ester, wherein the catalyst is produced by a method including the step of contacting it with a gas containing at least one selected from the group consisting of water, lower aliphatic carboxylic acid and lower aliphatic alcohol. Production. This article also relates to methods of producing the catalyst, and methods of using the catalyst to produce lower aliphatic carboxylic acid esters. The catalyst can exhibit high initial activity and high space-time yield, ensure a sufficiently long catalyst life in industrial implementation, and can prevent the generation of by-product substances.

Owner:SHOWA DENKO KK

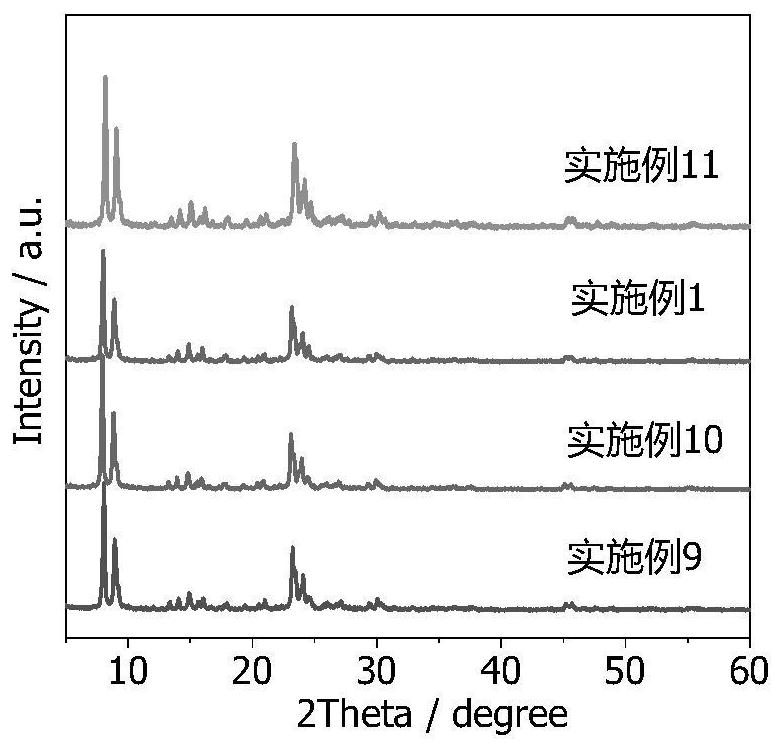

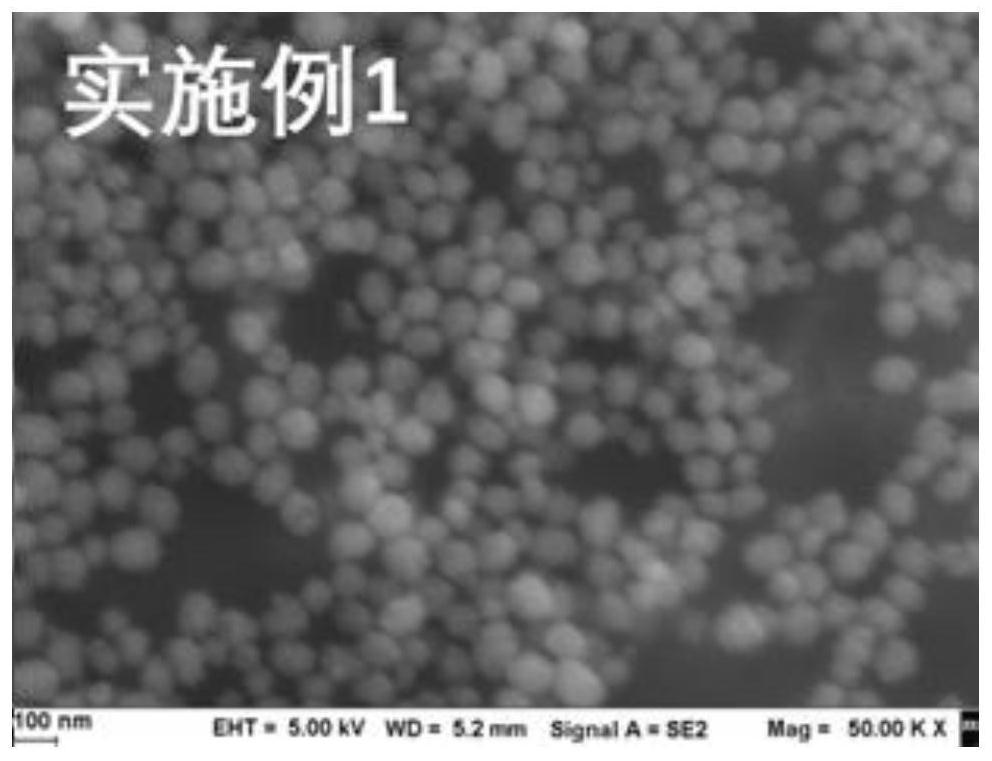

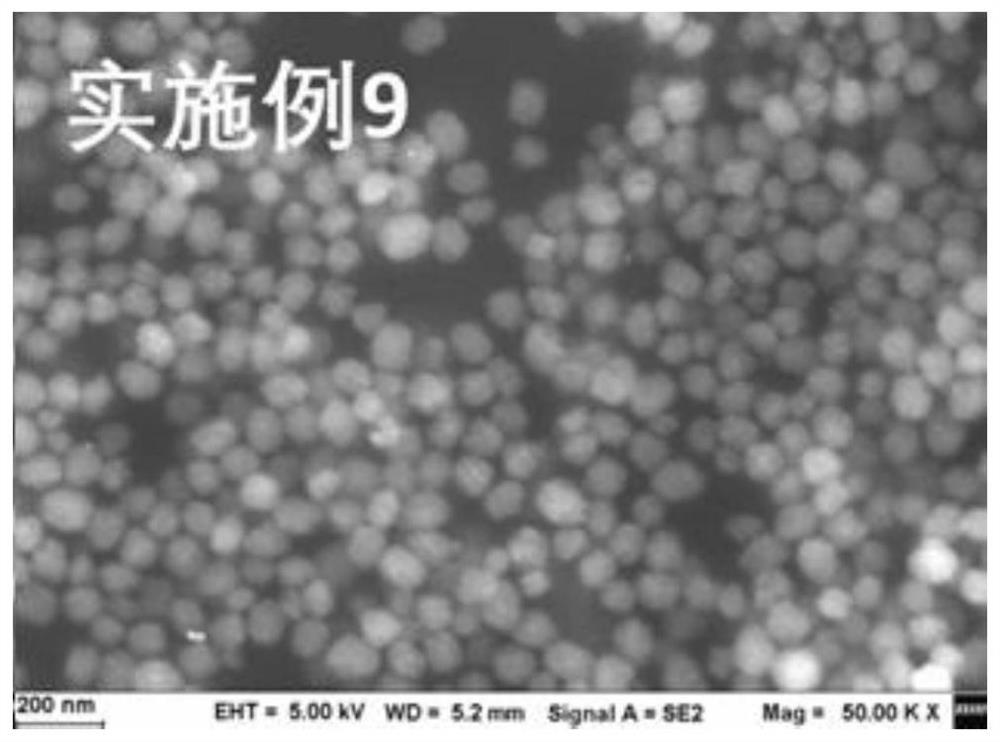

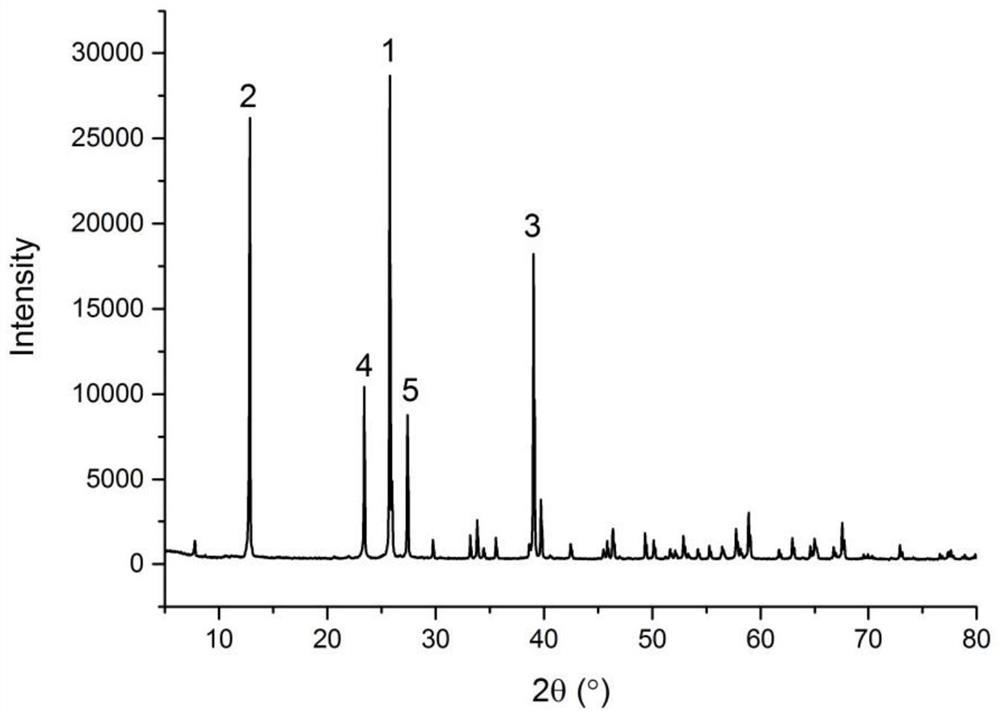

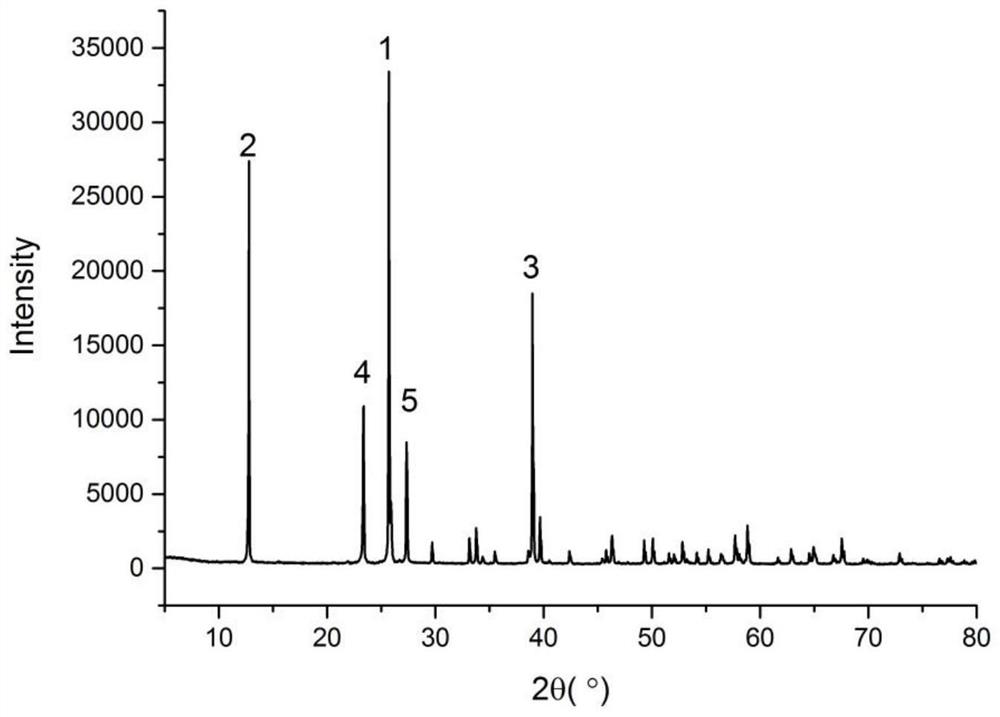

Molybdenum oxide and preparation method and application thereof

PendingCN113828322AHigh yieldUnique physical and chemical propertiesHeterogenous catalyst chemical elementsCatalyst activation/preparationPropeneMaterials science

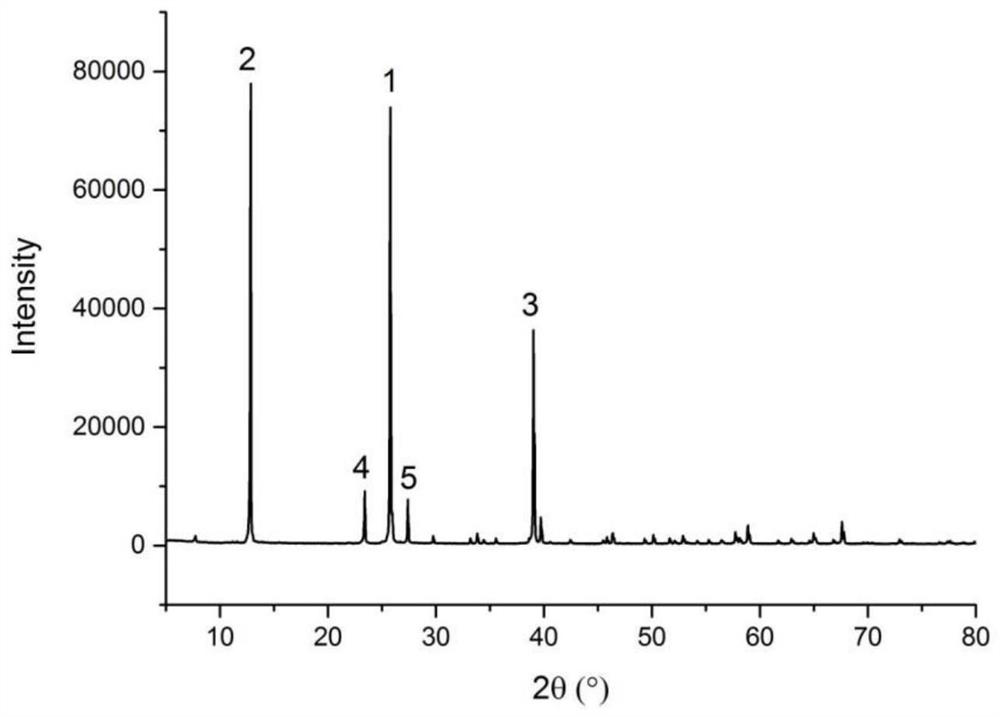

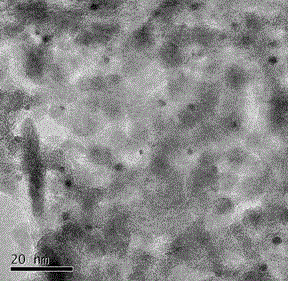

The invention provides molybdenum oxide as well as a preparation method and application thereof. The molybdenum oxide provided by the invention contains a silicon element, and the mass content of silicon is 0.8%-3.5%. According to the XRD spectrogram of the molybdenum oxide, the molybdenum oxide crystal phase 2theta has the strongest peak at 25.8 + / -1 degrees, the second strongest peak at 12.8 + / -1 degrees and the third strongest peak at 39.1 + / -1 degrees. The molybdenum oxide provided by the invention and a molybdenum catalyst form a supplementary system, and the supplementary system is used in a continuous supplement process of propylene ammoxidation reaction, so that a higher acrylonitrile yield can be obtained under a higher propylene load, and the acrylonitrile yield is kept stable for a long time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Saturated alkane dehydrogenation method

ActiveCN104588012ASimple processEasy to operateCatalyst activation/preparationHydrocarbonsProcess engineeringAlkane

The invention discloses a saturated alkane dehydrogenation method. According to the method, a presulfurization dehydrogenation catalyst and a reduced dehydrogenation catalyst are added into a reactor; conditions needed by a dehydrogenation reaction are regulated; and the dehydrogenation reaction is carried out. According to the invention, when the reduced dehydrogenation catalyst is prepared, SnPt alloy generation can be effectively inhibited, precious metal Pt utilization rate can be improved, and catalyst stability can be improved. The reduced dehydrogenation catalyst cooperates with the presulfurization dehydrogenation catalyst, such that a reduction process can be eliminated before the reaction. Therefore, an operation process can be simplified; operation cost can be reduced; and the catalysts as a whole have high initial activity, good selectivity, slow deactivation rate, and long service cycle.

Owner:CHINA PETROLEUM & CHEM CORP +1

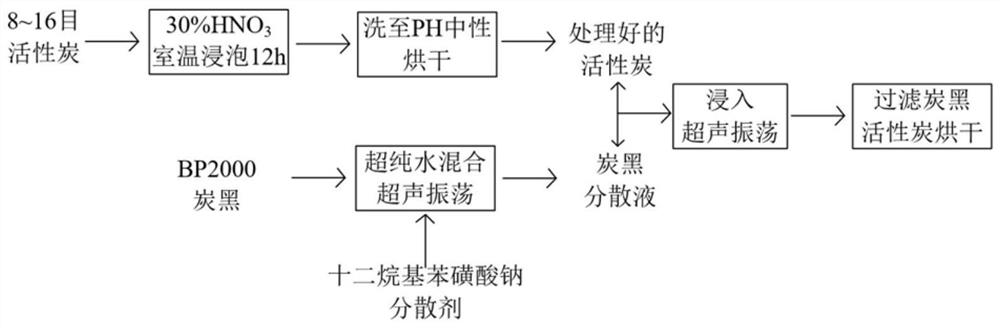

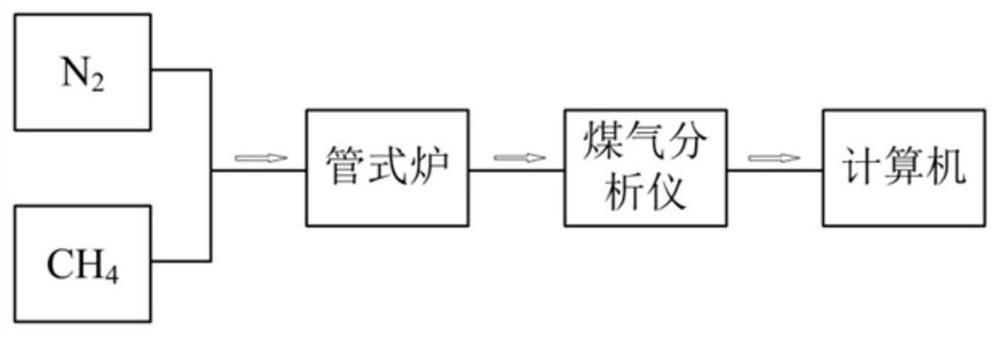

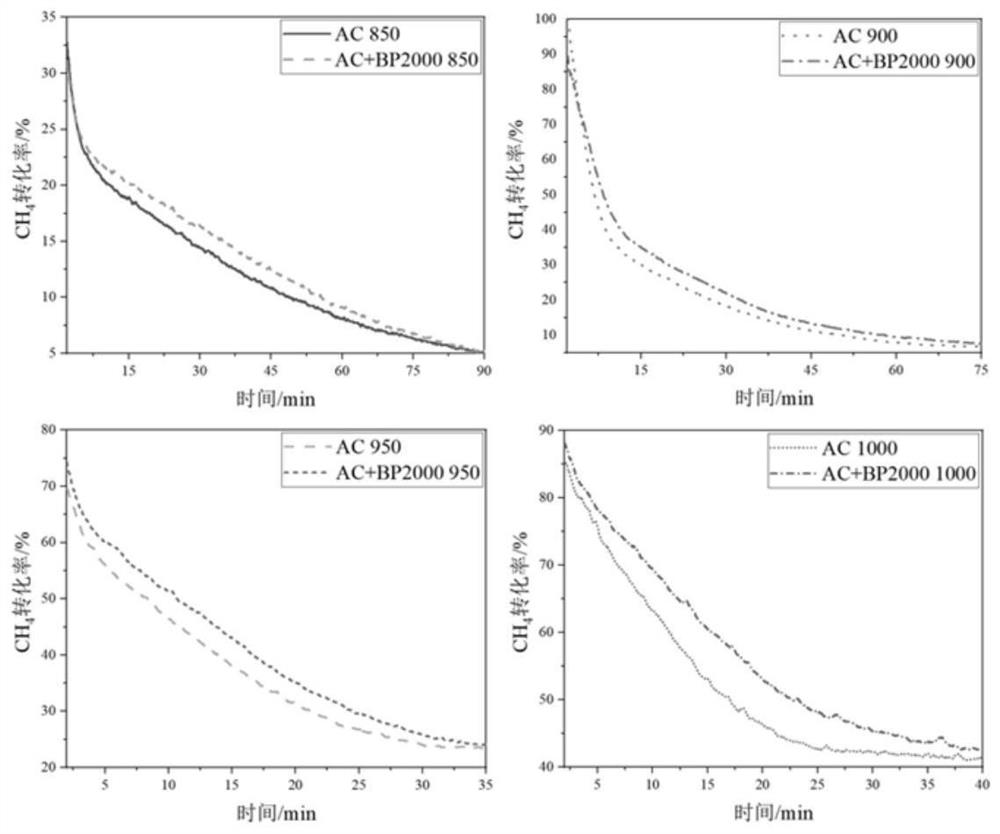

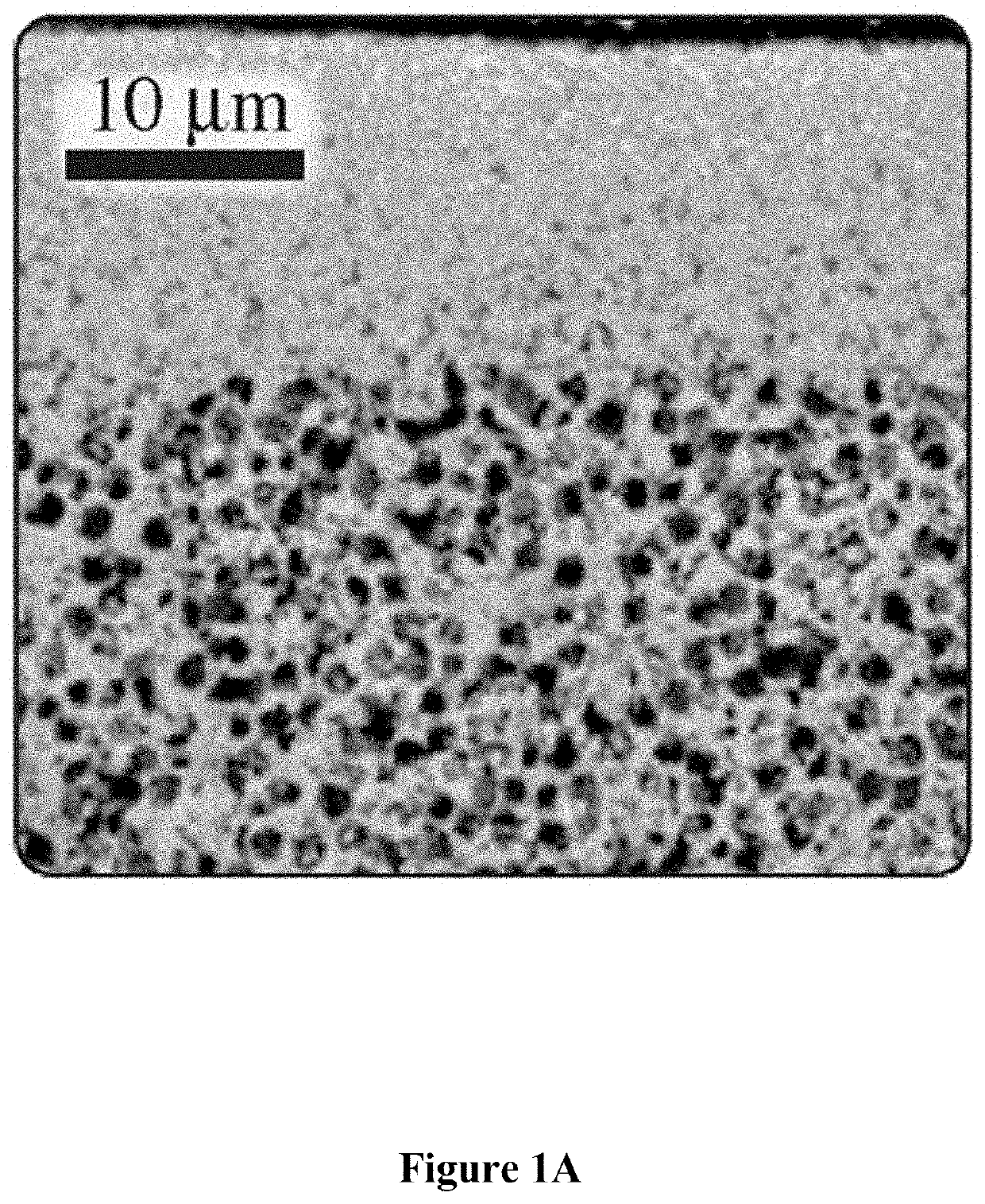

Method for stably catalyzing methane cracking hydrogen production by using carbon black enhanced activated carbon and application

ActiveCN113307225AReduce manufacturing costImprove economyHydrogenHydrogen/synthetic gas productionActivated carbonPtru catalyst

The invention discloses a method for stably catalyzing methane cracking hydrogen production by using carbon black enhanced activated carbon and application. According to the method, 8-16-mesh coconut shell activated carbon is adopted as a carrier to load carbon black, two carbon catalysts are combined through a series of preparation processes, and a reaction is performed at 850-1000 DEG C under normal pressure. According to the method, the conversion rate of a single activated carbon catalyst for catalyzing methane cracking hydrogen production is effectively improved, so that the activated carbon catalyst has a higher initial conversion rate and shows an inactivation delaying effect, and the method is a method for effectively improving the catalytic activity of cheap activated carbon. The method has important application value for industrial application of catalyzing methane cracking hydrogen production by the carbon catalyst and increasing the methane cracking conversion rate.

Owner:CHINA UNIV OF MINING & TECH

Methods of making ysz supported catalyst, and methods of using the same

PendingUS20210046456A1High synthesis rateHigh initial activityHeterogenous catalyst chemical elementsCatalyst activation/preparationAlkaline earth metalPtru catalyst

The present invention relates to catalysts, methods of making catalysts, and methods of using catalysts, where the catalysts include: at least one of a transition metal and a transition metal oxide supported by yttria-stabilized zirconia (YSZ), where the transition metal is promoted by at least one of an alkali metal and an alkaline-earth metal.

Owner:COLORADO SCHOOL OF MINES

A kind of method for preparing methyl acetate by carbonylation of dimethyl ether

ActiveCN108586247BImprove continuityAchieve stabilityMolecular sieve catalystsCatalyst activation/preparationPtru catalystCombinatorial chemistry

The invention provides a method for preparing methyl acetate by carbonylation of dimethyl ether. The method comprises the following steps: subjecting a mixed gas of dimethyl ether and carbon monoxideto carry out a dimethyl ether carbonylation reaction through activated hydrogen-type clinoptilolite to obtain methyl acetate, wherein the hydrogen-type clinoptilolite has an HEU topological structure.The method provided by the invention adopts the hydrogen-type clinoptilolite having the HEU topological structure as a catalyst, the catalyst has an 8-element pore structure, and silicon-aluminum isrelatively low, and can maintain relatively high activity for a long time in the dimethyl ether carbonylation reaction process, thereby realizing the continuity and stability of methyl acetate prepared by carbonylation of dimethyl ether, and also ensuring that methyl acetate has relatively high initial activity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com