Method for preparing methyl acetate by carbonylation of dimethyl ether

A technology of methyl acetate and dimethyl ether, which is applied in the field of dimethyl ether carbonylation to prepare methyl acetate, can solve the problems of non-continuous production of methyl acetate, fast deactivation of mordenite molecular sieve, poor stability, etc., and achieve continuity and stability, high methyl acetate selectivity, and high initial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention has no special limitation on the source of the hydrogen-type clinoptilolite. In the embodiment of the present invention, the preparation method of the hydrogen-type clinoptilolite preferably includes the following steps:

[0029] (1) Sodium-potassium clinoptilolite is immersed in an ammonium nitrate aqueous solution, and ion exchange is performed to obtain ammonium clinoptilolite;

[0030] (2) The ammonium-type clinoptilolite is sequentially dried and roasted to obtain the hydrogen-type clinoptilolite.

[0031] In the present invention, the sodium-potassium clinoptilolite is preferably immersed in an ammonium nitrate aqueous solution for ion exchange to obtain the ammonium clinoptilolite. In the present invention, in the ion exchange process, the balance cation (Na + 、K + ) and NH 4 + exchanged to obtain ammonium clinoptilolite.

[0032] In the present invention, the particle size of the sodium-potassium clinoptilolite is preferably 1-10 μm, m...

Embodiment 1

[0055] (1) Take 50g of sodium-potassium clinoptilolite (Luoyang Jianlong Micro-Na New Material Co., Ltd., model H-06) and add it to 1500mL of NH with a concentration of 1mol / L 4 NO 3 In an aqueous solution, ion-exchange at a constant temperature of 80° C. for 5 hours, and then the obtained product is washed with deionized water and dried, and the above-mentioned ion-exchange process is repeated twice to obtain ammonium-type clinoptilolite; the ammonium-type clinoptilolite is ℃ drying for 12 hours, and then roasting at 540 ℃ for 6 hours in an air atmosphere to obtain hydrogen-type clinoptilolite; the hydrogen-type clinoptilolite has an 8-membered pore structure and an average particle size of 3 μm;

[0056] (2) Use the hydrogen-type clinoptilolite obtained in step (1) as a catalyst, put it into a fixed-bed reactor, and roast it at 500° C. for 2 h under a nitrogen atmosphere to obtain activated hydrogen-type clinoptilolite; lower the bed temperature To 190°C, control the pressu...

Embodiment 2

[0059] (1) adopt the method described in embodiment 1 to prepare hydrogen clinoptilolite;

[0060] (2) Use the hydrogen-type clinoptilolite obtained in step (1) as a catalyst, put it into a fixed-bed reactor, and roast it at 500° C. for 2 h under a nitrogen atmosphere to obtain activated hydrogen-type clinoptilolite; lower the bed temperature To 190°C, control the pressure to 1MPa, introduce a mixed gas with a molar ratio of dimethyl ether and carbon monoxide of 1:10, maintain the pressure at 1MPa, control the space velocity of the mixed gas to 1000mL / (g h), and carry out dimethyl ether carbonyl reaction to produce methyl acetate.

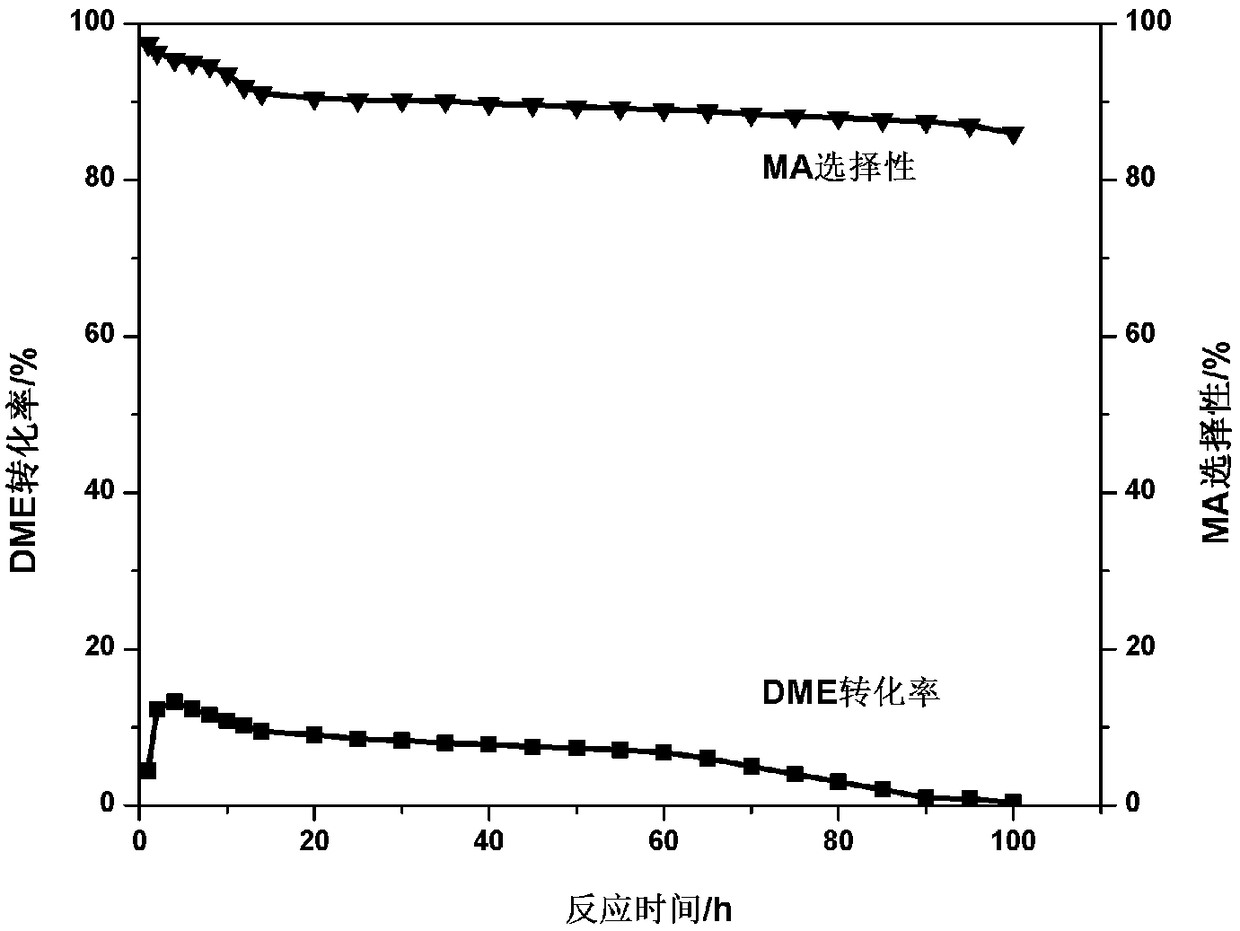

[0061] The reaction process of the preparation method of the present embodiment is detected, and the obtained results are shown in image 3 , in the preparation method provided in this example, the initial maximum conversion rate of dimethyl ether is 13.21%, and the initial maximum selectivity of methyl acetate is 97.43%, and the conversion rate o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com