Catalyst for preparation of styrene

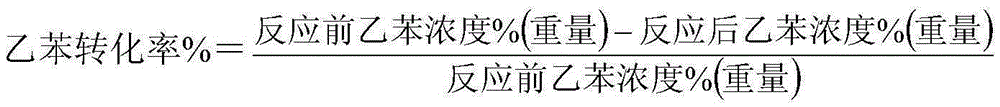

A catalyst and styrene technology, applied in the direction of heterogeneous catalyst chemical elements, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low initial activity and induction period of catalysts with low cerium content long wait question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

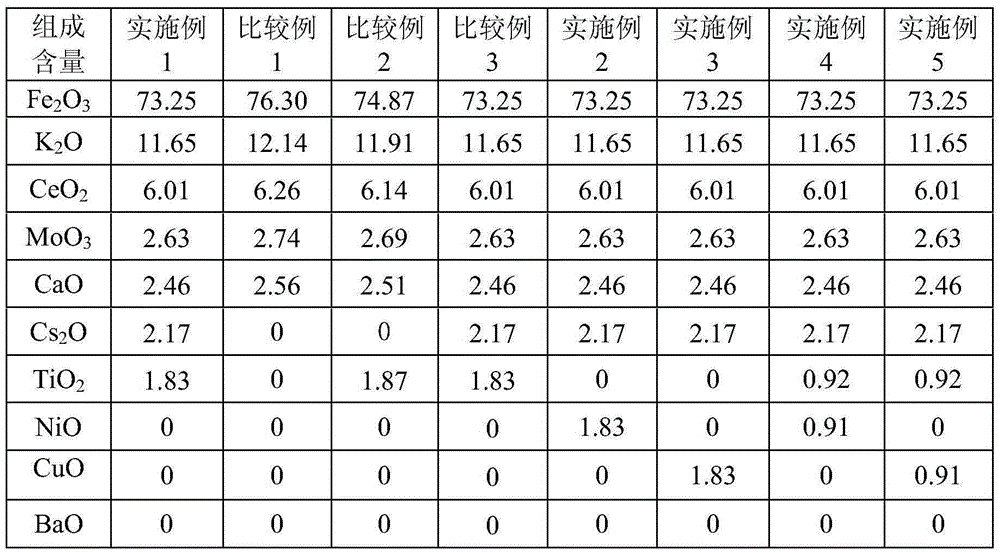

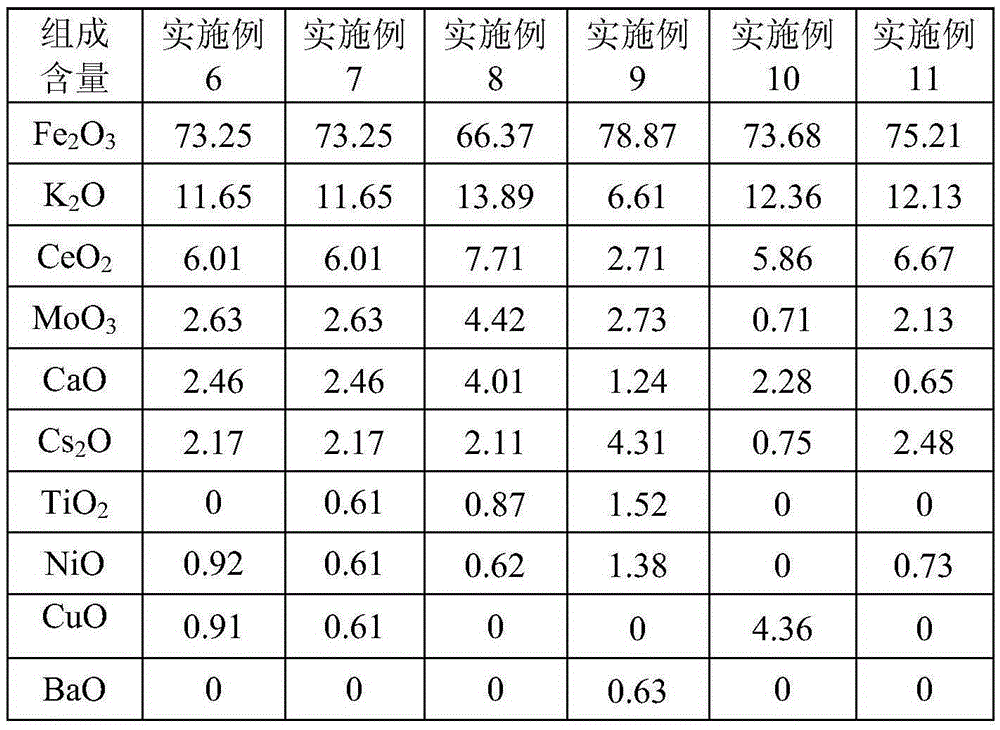

Embodiment 1

[0031] Will be equivalent to 52.32 parts Fe 2 O 3 Iron oxide red, equivalent to 20.93 parts of Fe 2 O 3 Of iron oxide yellow, equivalent to 11.65 parts of K 2 Potassium carbonate of O, equivalent to 6.01 parts of CeO 2 Of cerium oxalate, equivalent to 2.63 parts of MoO 3 Ammonium molybdate, calcium carbonate equivalent to 2.46 parts CaO, 1.83 parts TiO 2 Stir 3.9 parts of sodium carboxymethyl cellulose in a kneader for 1.8 hours, add deionized water accounting for 25.8% of the total weight of the catalyst raw material, mix for 0.7 hours, take out the extruded bar, and squeeze it into particles with a diameter of 3 mm and a length of 5 mm. Put it in an oven, bake at 60°C for 3 hours, and bake at 100°C for 10 hours, and then place it in a muffle furnace and calcinate at 800°C for 4 hours to obtain a semi-finished catalyst. Will be equivalent to 2.17 Cs 2 O cesium nitrate is dissolved in a suitable amount of water, the semi-finished catalyst is immersed in this solution for 10 hours...

Embodiment 2

[0046] In addition to replacing TiO with NiO 2 In addition, the catalyst preparation method and catalyst evaluation conditions are the same as in Example 1, specifically:

[0047] Will be equivalent to 52.32 parts Fe 2 O 3 Iron oxide red, equivalent to 20.93 parts of Fe 2 O 3 Of iron oxide yellow, equivalent to 11.65 parts of K 2 Potassium carbonate of O, equivalent to 6.01 parts of CeO 2 Of cerium oxalate, equivalent to 2.63 parts of MoO 3 Ammonium molybdate, calcium carbonate equivalent to 2.46 parts CaO, 1.83 parts NiO and 3.9 parts sodium carboxymethyl cellulose were stirred in a kneader for 1.8 hours, and 25.8% of the total weight of the catalyst raw material was added to deionized water and mixed for 0.7 hours , Take out the extruded bar, squeeze into pellets with a diameter of 3 mm and a length of 5 mm, put them in an oven, bake at 60°C for 3 hours, 100°C for 10 hours, and then place in a muffle furnace and calcinate at 800°C for 4 hours to obtain a semi-finished catalyst. ...

Embodiment 3

[0050] In addition to replacing TiO with CuO 2 In addition, the catalyst preparation method and catalyst evaluation conditions are the same as in Example 1, specifically:

[0051] Will be equivalent to 52.32 parts Fe 2 O 3 Iron oxide red, equivalent to 20.93 parts of Fe 2 O 3 Of iron oxide yellow, equivalent to 11.65 parts of K 2 Potassium carbonate of O, equivalent to 6.01 parts of CeO 2 Of cerium oxalate, equivalent to 2.63 parts of MoO 3 Ammonium molybdate, calcium carbonate equivalent to 2.46 parts CaO, 1.83 parts CuO and 3.9 parts sodium carboxymethyl cellulose were stirred in a kneader for 1.8 hours, and 25.8% of the total weight of the catalyst raw material was added to deionized water and mixed for 0.7 hours , Take out the extruded bar, squeeze into pellets with a diameter of 3 mm and a length of 5 mm, put them in an oven, bake at 60°C for 3 hours, 100°C for 10 hours, and then place in a muffle furnace and calcinate at 800°C for 4 hours to obtain a semi-finished catalyst. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com