Method for stably catalyzing methane cracking hydrogen production by using carbon black enhanced activated carbon and application

A technology of activated carbon and carbon black, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problem of rapid catalyst deactivation and achieve low production cost and high economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

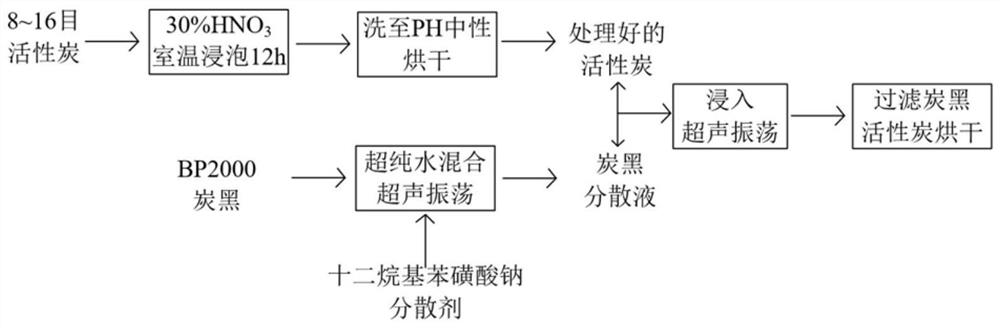

[0054] A method for using carbon black to enhance activated carbon to stably catalyze methane cracking to produce hydrogen, that is, the preparation process of the catalyst is as follows figure 1 shown.

[0055] Wash the activated carbon catalyst, dry it, and put it into 30% HNO 3 After soaking in the solution for 12 hours, wash the activated carbon with ultrapure water until the filtrate is neutral, and then dry it;

[0056] Add 30ml of ultra-pure water for every 1g of carbon black to disperse evenly,

[0057] Put 0.5g of dispersant into 150ml ultrapure water and mix well;

[0058] Mix according to the volume ratio of carbon black solution and sodium dodecylpropanesulfonate dispersant to be 10:1, through 0.5h ultrasonic vibration, mechanical stirring simultaneously, make carbon black dispersion liquid;

[0059] Mix according to the mass ratio of activated carbon and carbon black BP2000 of 20:5, ultrasonically oscillate and mechanically stir for 1 hour, then sieve out the a...

Embodiment 2

[0063] A method for using carbon black to enhance activated carbon to stably catalyze methane cracking to produce hydrogen, that is, the preparation process of the catalyst is as follows figure 1 shown.

[0064] Wash the activated carbon catalyst, dry it, and put it into 30% HNO 3 After soaking in the solution for 12 hours, wash the activated carbon with ultrapure water until the filtrate is neutral, and then dry it;

[0065] Add 50ml of ultra-pure water for every 1g of carbon black to disperse evenly,

[0066] Put 0.5g of dispersant into 150ml ultrapure water and mix well;

[0067] Mix according to the volume ratio of carbon black solution and sodium dodecylpropanesulfonate dispersant as 6:1, through 0.5h ultrasonic vibration, mechanical stirring at the same time, make carbon black dispersion liquid;

[0068] Mix according to the mass ratio of activated carbon and carbon black BP2000 of 20:3, ultrasonically oscillate and mechanically stir for 1 hour, then sieve out the act...

Embodiment 3

[0072] Except that the mass ratio of activated carbon and carbon black is 20:4, the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com