Catalyst for synthesizing aniline through nitrobenzene liquid phase hydrogenation and preparation method thereof

A technology of nitrobenzene liquid and catalyst, which is applied to the preparation of amino compounds, catalyst carriers, chemical instruments and methods, etc. It can solve the problems of catalysts such as poor resistance to high-temperature tar poisoning, difficulty in industrial production, and insufficient spreading performance. Industrialization promotion, step simplification, good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

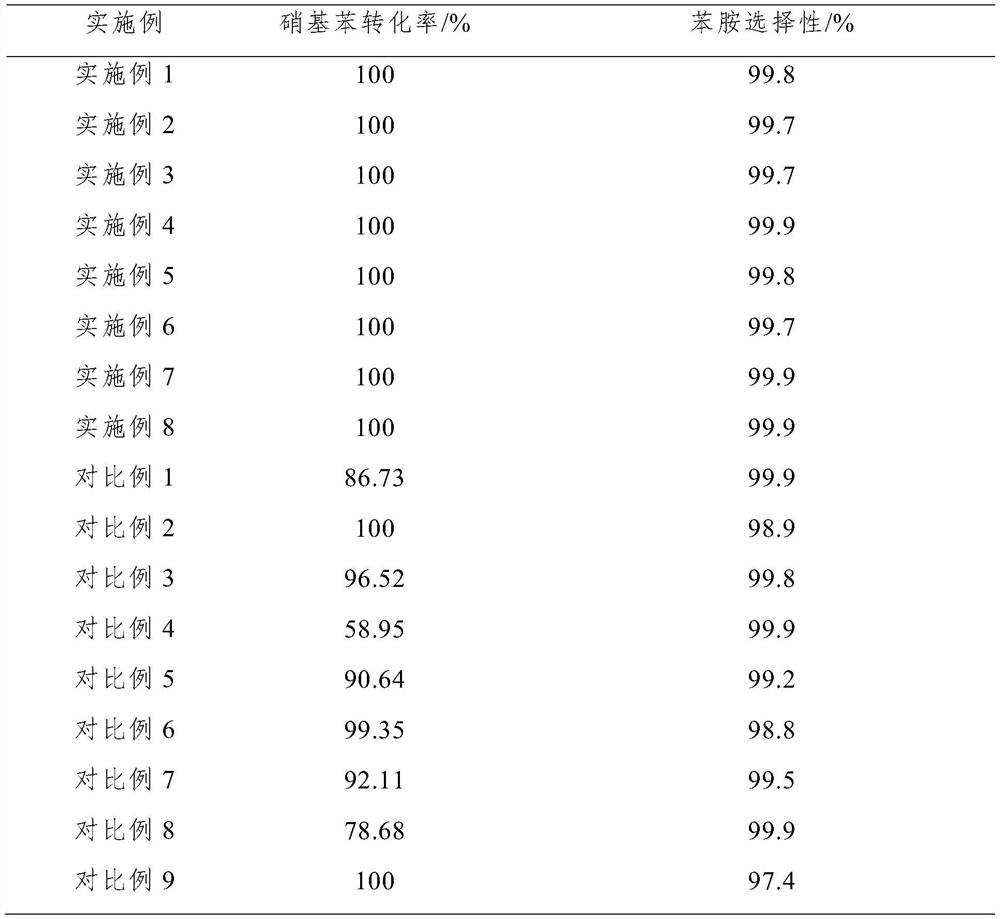

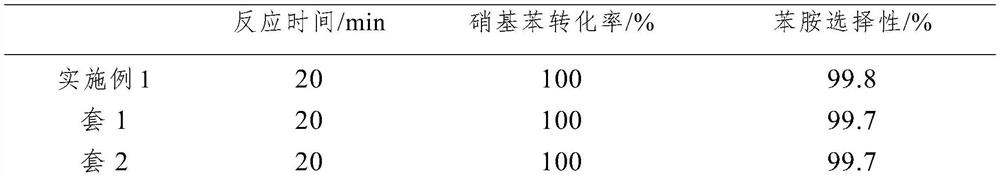

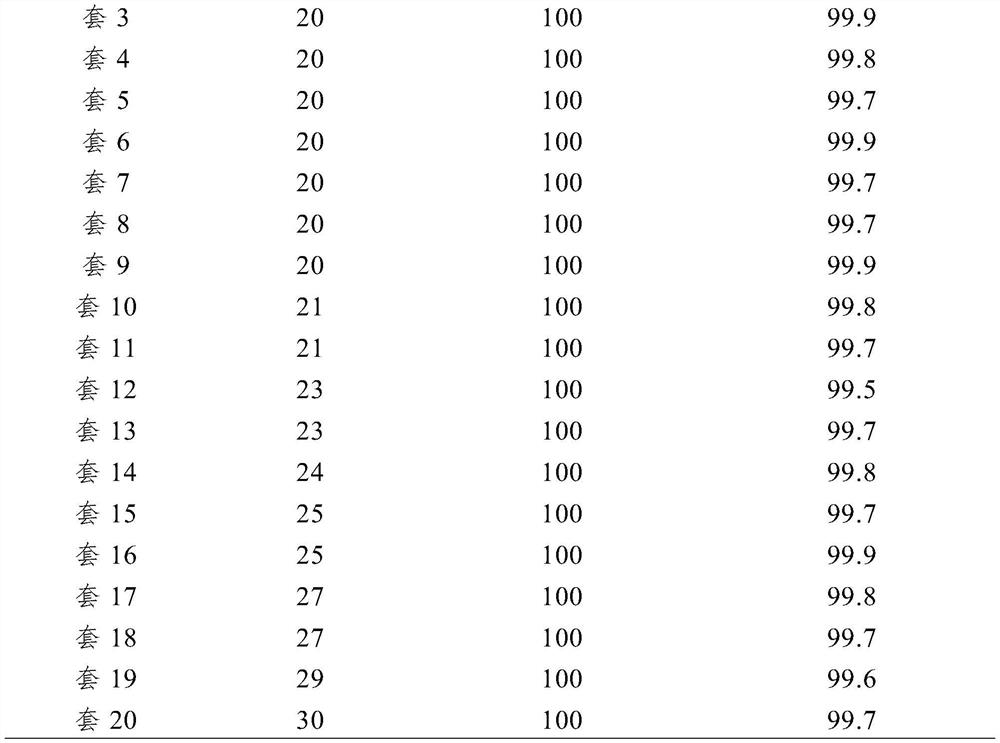

Examples

Embodiment 1

[0029] This embodiment provides a catalyst for the synthesis of aniline by liquid-phase hydrogenation of nitrobenzene. The catalyst raw material includes carbon nanotubes after surface modification and precursor atomized particles containing active components and additives. The mass of the active components is 3% of the mass of the catalyst, the quality of the catalyst is 1.5% of the mass of the catalyst, the active component is Pt, the promoters are Ru and Cr, and the quality of Ru is 1.0% of the mass of the catalyst , the quality of Cr is 0.5% of the catalyst quality;

[0030] This example provides a method for preparing the catalyst for the synthesis of aniline by liquid-phase hydrogenation of nitrobenzene using carbon nanotubes after surface modification and precursor atomized particles containing active components and additives as raw materials, specifically :

[0031] Step 1, 50g of the average particle size is 12μm, the specific surface area is 1000cm 2 / g, carbon nan...

Embodiment 2

[0038] This embodiment provides a catalyst for the synthesis of aniline by liquid-phase hydrogenation of nitrobenzene. The catalyst raw material includes carbon nanotubes after surface modification and precursor atomized particles containing active components and additives. The mass of the active components is 3% of the mass of the catalyst, the quality of the catalyst is 1% of the mass of the catalyst, the active component is Pt, the promoters are Ni and W, and the quality of Ni is 0.5% of the mass of the catalyst , the quality of W is 0.5% of the catalyst mass;

[0039] This example provides a method for preparing the catalyst for the synthesis of aniline by liquid-phase hydrogenation of nitrobenzene using carbon nanotubes after surface modification and precursor atomized particles containing active components and additives as raw materials, specifically :

[0040] Step 1. Take 50g of 2 / g, carbon nanotubes with an average pore diameter of 8nm, 15mL of ferric chloride solu...

Embodiment 3

[0047] This embodiment provides a catalyst for the synthesis of aniline by liquid-phase hydrogenation of nitrobenzene. The catalyst raw material includes carbon nanotubes after surface modification and precursor atomized particles containing active components and additives. The mass of the active components is 3% of the mass of the catalyst, the quality of the catalyst is 0.6% of the mass of the catalyst, the active component is Pt, the promoters are Ru and La, and the quality of Ru is 0.5% of the mass of the catalyst , the quality of La is 0.1% of the catalyst mass;

[0048] This example provides a method for preparing the catalyst for the synthesis of aniline by liquid-phase hydrogenation of nitrobenzene using carbon nanotubes after surface modification and precursor atomized particles containing active components and additives as raw materials, specifically :

[0049] Step 1, 50g of the average particle size is 14μm, the specific surface area is 1400cm 2 / g, carbon nanotu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com