Vinyl polymerization catalyst and preparing method thereof

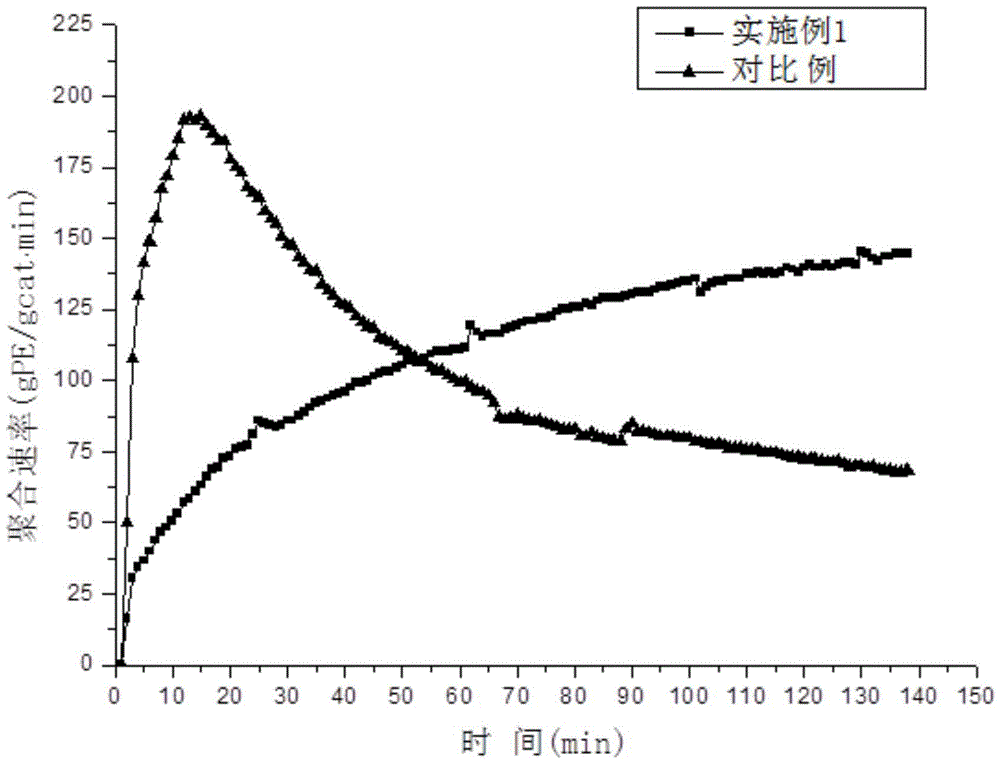

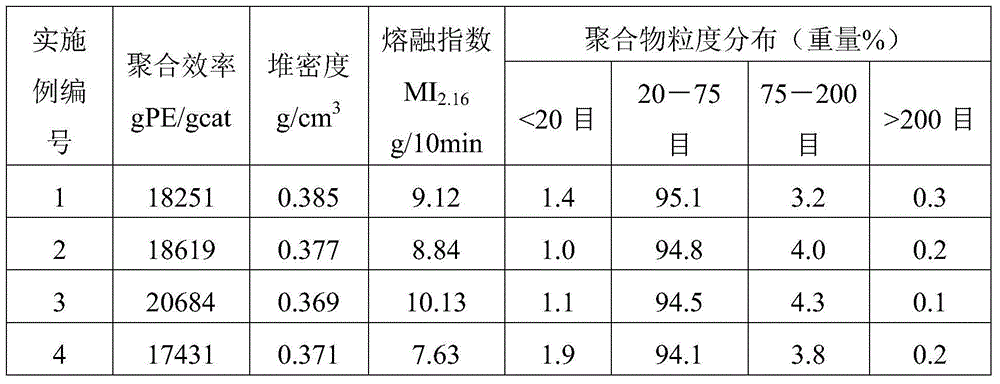

A technology of ethylene polymerization and catalyst, which is applied in the field of ethylene polymerization catalyst and its preparation, which can solve the problems of affecting the shape of final polymer particles, poor reaction stability, and high initial polymerization activity, and achieve increased strength, concentrated particle size distribution, and stable polymerization reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Catalyst preparation:

[0053] (1) At room temperature and under the protection of nitrogen, add 80ml of hexane solution of 0.8186mol / L dibutylmagnesium compound, 80ml of hexane and 2.428g of triethylaluminum to a 0.5 liter reactor with electromagnetic stirring , and stirred for 0.5 hours. Then, a solution consisting of 19.468 g of diethylhexanol and 40 ml of hexane was slowly added with a metering pump at a constant speed for 35 minutes, and the reaction was maintained for 1 hour after the addition. Finally, 6.1 g of epichlorohydrin was added, the temperature was raised to 50° C., and the reaction was kept for 2 hours to obtain magnesium complex solution A;

[0054] (2) Cool the reactor to -25°C, slowly add the solution formed by 11.42g of titanium tetrachloride and 40ml of hexane with a metering pump at a constant speed, the addition time is 45 minutes, and keep it at this temperature for 2 hours after the addition is completed. Obtain solution B;

[0055] (3) Afte...

Embodiment 2

[0063] Catalyst preparation:

[0064] (1) At room temperature and under the protection of nitrogen, add 70ml of heptane solution of butyloctylmagnesium compound with a concentration of 1.0336mol / L to a 0.5 liter reactor with electromagnetic stirring, 80ml of n-heptane and triisobutyl Aluminum 8.14g, stirred and reacted for 0.5 hours. Then, a solution consisting of 26.66 g of diethylhexanol and 40 ml of heptane was slowly added with a metering pump at a constant speed for 1.0 hr, and the reaction was maintained for 2 hours after the addition was completed. Finally, 6.8g of tetrahydrofuran was added, the temperature was raised to 50°C, and the reaction was kept for 2 hours to obtain magnesium complex solution A;

[0065] (2) Cool the reaction kettle to -15°C, slowly add the solution formed by 7.16g of titanium tetrachloride and 30ml of heptane with a metering pump at a constant speed, the addition time is 0.5 hours, and keep it at this temperature for 3 hours after the addition...

Embodiment 3

[0072] Catalyst preparation:

[0073] (1) At room temperature and under the protection of nitrogen, add 80ml of hexane solution of dibutylmagnesium compound with a concentration of 0.8186mol / L, 80ml of hexane and 3.86 g, stirring the reaction for 1 hour. Then, a solution consisting of 9.77 g of isobutanol and 40 ml of hexane was slowly added with a metering pump at a constant speed for 35 minutes, and the reaction was maintained for 1 hour after the addition was completed. Finally, 13.4g of epichlorohydrin was added, the temperature was raised to 50°C, and the reaction was kept for 2 hours to obtain magnesium complex solution A;

[0074] (2) Cool the reactor to -30°C, slowly add the solution formed by 23.1g of titanium tetrachloride and 60ml of hexane with a metering pump at a constant speed, the addition time is 1.5 hours, keep the reaction at this temperature for 2 hours after the addition is complete, Obtain solution B;

[0075] (3) After replacing the nitrogen in the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com