Activation method of butene oxidative dehydrogenation catalyst

A technology of oxidative dehydrogenation and activation methods, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of shortened service life, low initial activity, long induction period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

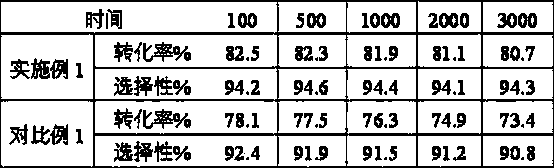

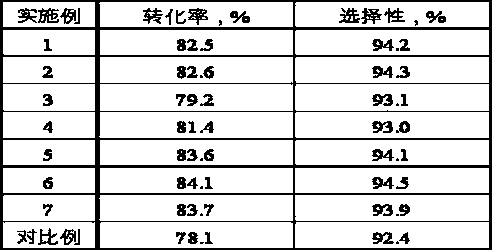

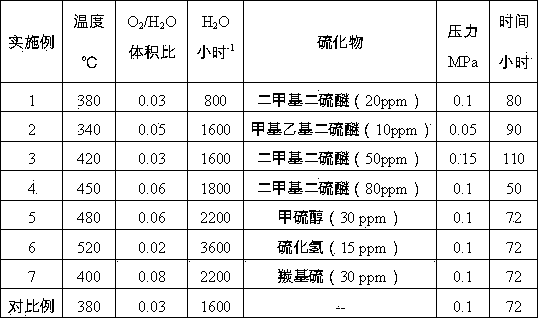

[0021] In a 1.5-liter adiabatic two-stage reactor, an iron-based spinel oxidative dehydrogenation catalyst is used, at an activation temperature of 380°C, an oxygen / water vapor volume ratio of 0.03, and a water vapor volume space velocity of 800 hours -1 , the concentration of dimethyl disulfide is 20ppm, and the system pressure is 0.1MPa and treated for 80 hours. The specific treatment conditions are shown in Table 1.

[0022] Stop the feeding of dimethyl disulfide, wait until the system reaches the reaction conditions, the butene feed starts to react, at 380°C, the volume space velocity of butene is 400 hours -1 , O 2 / C 4 h 8 The performance evaluation was carried out under the conditions of 0.7 and water-ene ratio of 12, and the reaction results are shown in Table 2.

[0023]

Embodiment 2

[0025] The activation temperature is controlled at 340°C, the oxygen / water vapor volume ratio is 0.05, and the water vapor volume space velocity is 1600h -1 , Methyl ethyl disulfide concentration 10ppm, system pressure 0.05MPa after 90 hours of treatment under the conditions, the rest are the same as [Example 1].

[0026]

Embodiment 3

[0028] The activation temperature is controlled at 420°C, the oxygen / water vapor volume ratio is 0.03, and the water vapor volume space velocity is 1600h -1 , dimethyl disulfide concentration 50ppm, system pressure 0.15MPa under the conditions of 110 hours, the rest are the same as [embodiment 1].

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com