Sulfur tail gas hydrogenation catalyst and preparation method

A hydrogenation catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of incomplete catalyst vulcanization, unstable catalyst activity, and easy overheating, etc., and achieve significant Economic and social benefits, avoiding excessive discharge of SO2, and high initial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

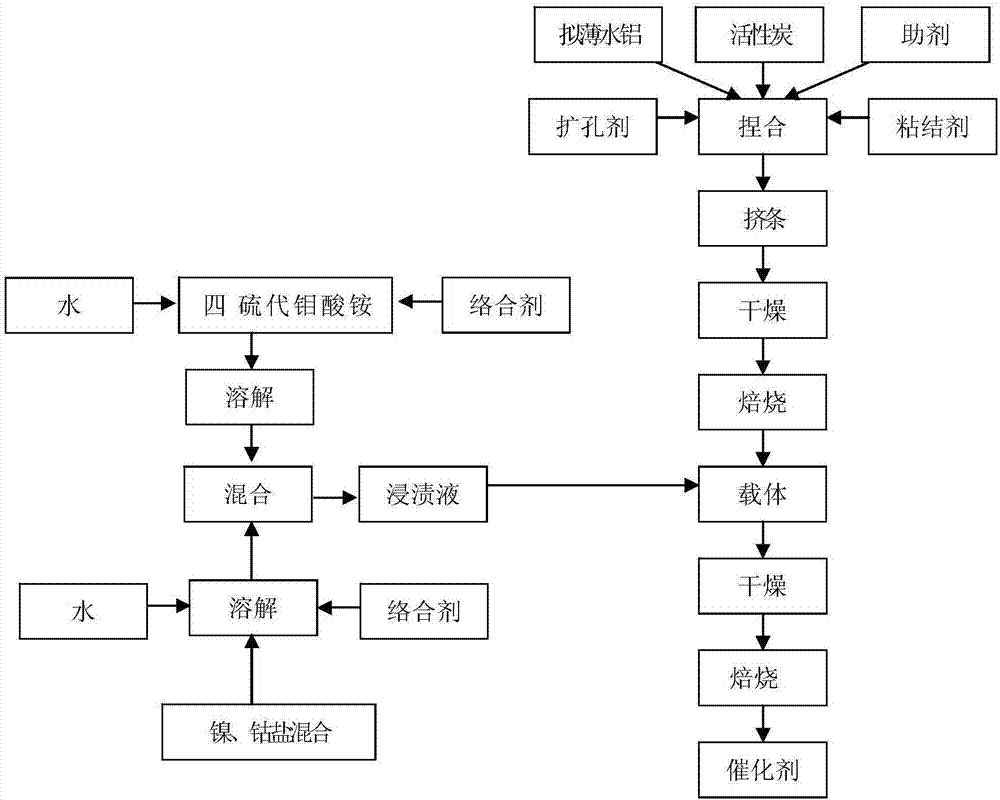

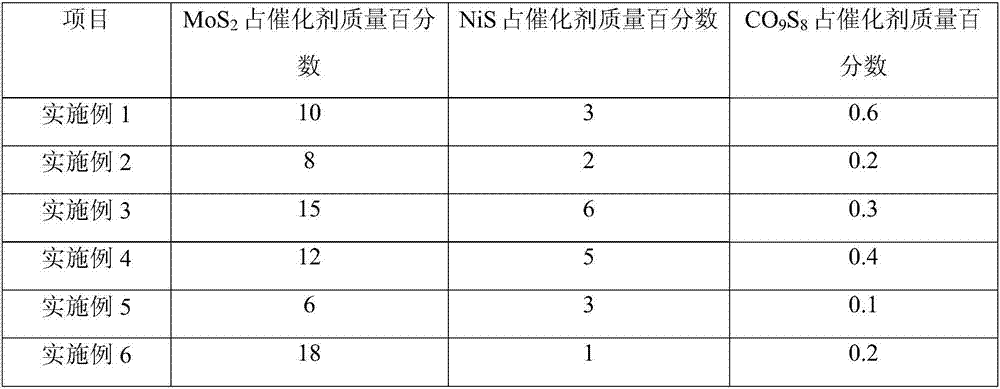

[0041] With 200 grams of pseudo-boehmite (specific surface area is 300m 2 / g), 25 grams of basic activated carbon, 3 grams of calcium oxide, 4 grams of scallop powder, 28 grams of nitric acid, and 270 grams of deionized water are mixed uniformly, extruded on the extruder, dried at 120°C for 4 hours, and dried at 500 ℃ for 4 hours to prepare the catalyst carrier.

[0042] Get 80ml of deionized water, add 20ml of diethylenetriamine and stir to form a diethylenetriamine solution, add 26g of ammonium tetrathiomolybdate in the diethylenetriamine solution, and make it form a stable solution under heating and stirring; Add 5ml of phosphoric acid to 80ml of deionized water, mix 5.52g of basic nickel carbonate and 2.66g of cobalt nitrate hexahydrate evenly, add to the aqueous solution containing phosphoric acid, and stir until completely dissolved. The above two solutions are mixed, stirred evenly, and constant volume to obtain the active component impregnation solution. The carrier ...

Embodiment 2

[0046] With 180 grams of pseudo-boehmite (specific surface area is 300m2 / g), 10 grams of basic activated carbon, 2 grams of calcium oxide, 4 grams of scallop powder, 35 grams of nitric acid, and 250 grams of deionized water are mixed uniformly, extruded on the extruder, dried at 120°C for 4 hours, and dried at 500 ℃ for 4 hours to prepare the catalyst carrier.

[0047] Take 80ml of deionized water, add 15ml of methanol and stir to form a methanol solution, add 32.5g of ammonium tetrathiomolybdate into the methanol solution, heat and stir to form a stable solution; take 6g of citric acid and add 70ml of deionized water , mix 8.28g basic nickel carbonate and 0.73g basic cobalt carbonate, add to the aqueous solution containing citric acid, and stir until completely dissolved. The above two solutions are mixed, stirred evenly, and constant volume to obtain the active component impregnation solution. The carrier impregnated with the co-impregnation solution was dried at 110°C for...

Embodiment 3

[0051] With 190 grams of pseudo-boehmite (specific surface area is 300m 2 / g), 30 gram alkaline activated carbon, 4 gram sodium carbonate, 4 gram safflower powder, 30 gram nitric acid, 280 gram deionized water mix uniformly, extrude molding on extruder, dry 4 hours at 120 ℃, at 450 ℃ for 4 hours to prepare the catalyst carrier.

[0052] Take 100ml of deionized water, add 20ml of ethanolamine and stir to form an ethanolamine solution, add 48.75g of ammonium tetrathiomolybdate into the ethanolamine solution, and heat and stir to form a stable solution; add 5g of acetic acid to 60ml of deionized water, Mix 38.4g of nickel nitrate hexahydrate and 2.0g of cobalt nitrate hexahydrate evenly, add it into the aqueous solution containing phosphoric acid, and stir until completely dissolved. The above two solutions are mixed, stirred evenly, and constant volume to obtain the active component impregnation solution. The carrier was impregnated with the co-impregnation solution for 1 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com