Method for activating ethylbenzene dehydrogenation

A dehydrogenation catalyst and ethylbenzene dehydrogenation technology, which is applied in the activation field of ethylbenzene dehydrogenation catalyst, can solve the problems of long induction period, low catalyst initial activity, incomplete catalyst activation, etc., and achieve initial activity improvement and activation temperature reduction , to meet the effect of long-term operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

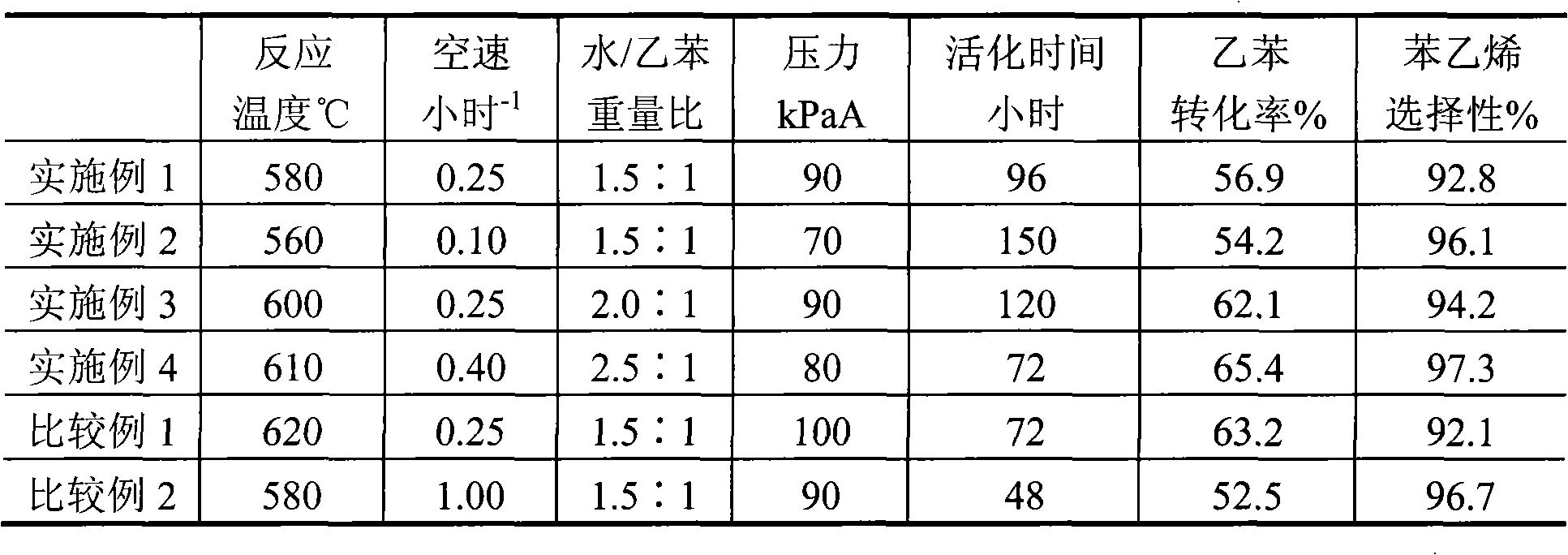

Examples

Embodiment 1

[0010] In the adiabatic negative pressure two-stage reactor, the reaction temperature is controlled at 580°C, the water / ethylbenzene weight ratio is 1.5:1, and the ethylbenzene space velocity is 0.25 hours -1 , Under the condition of negative pressure of 90kPaA, the activation time is 96 hours. Ethylbenzene and water vapor are mixed uniformly and passed into the reactor. The reaction product was condensed and sampled for chromatographic analysis to obtain ethylbenzene conversion, styrene selectivity and styrene yield. The results are shown in Table 1.

Embodiment 2

[0012] Adjust the reaction temperature to 560°C and change the ethylbenzene space velocity to 0.10 hours -1 , Negative pressure is made as 70kPaA, and activation time is 150 hours, and all the other are with embodiment 1.

Embodiment 3

[0014] The reaction temperature is 600°C, the weight ratio of water / ethylbenzene is changed to 2.0:1, and the space velocity of ethylbenzene is changed to 0.50 hours -1 , the activation time is 120 hours, and all the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com