Modified Co-based catalyst and preparation method and application thereof, and method for preparing propylene through anaerobic dehydrogenation of propane

A catalyst and modification technology, applied in the field of propane oxygen-free dehydrogenation to propylene, modified Co-based catalyst and its preparation, can solve the problems of poor catalytic activity, poor catalyst stability, poor propane conversion rate and propylene selectivity, etc. Achieve the effects of improving reaction performance, improving dispersion, and improving regeneration stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The present invention also provides a method for preparing the modified Co-based catalyst described in the above technical solution, comprising the following steps:

[0064] a) After mixing the precursor of the auxiliary agent, the carrier Silicalite-1 and the solvent, roasting is carried out to obtain the intermediate M / S-1;

[0065] b) The intermediate M / S-1 is mixed with the precursor of the active component, and then calcined to obtain a modified Co-based catalyst.

[0066] Regarding step a): After mixing the precursor of the auxiliary agent, the carrier Silicalite-1 and the solvent, roasting is carried out to obtain the intermediate M / S-1.

[0067] In the present invention, the type of the auxiliary agent in the precursor of the auxiliary agent is consistent with that described in the previous technical scheme, that is, the metal M and / or the oxide of the metal M, wherein the metal M is selected from Mg, Zr, Nd, W , one or more of La, Ce and Zn. In the present in...

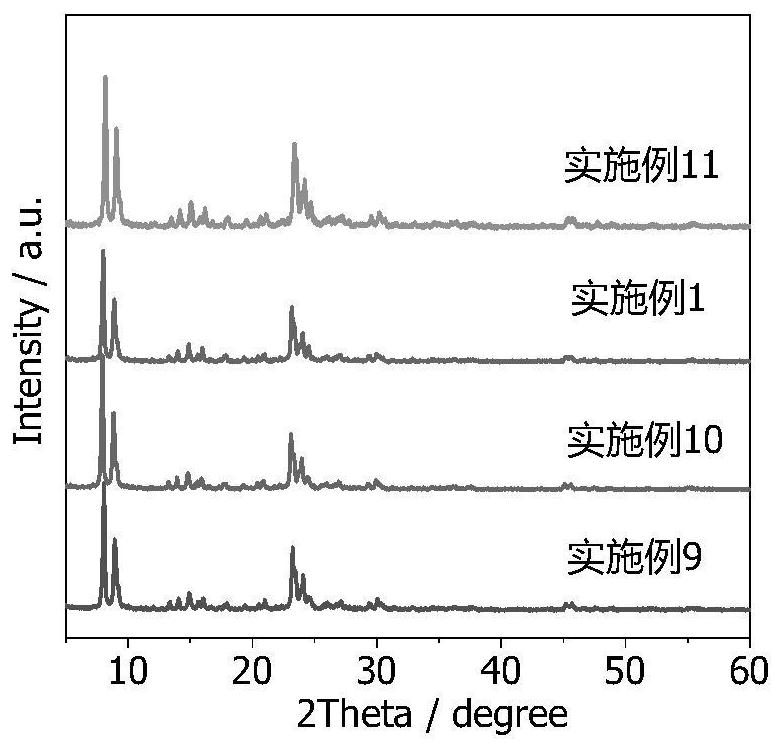

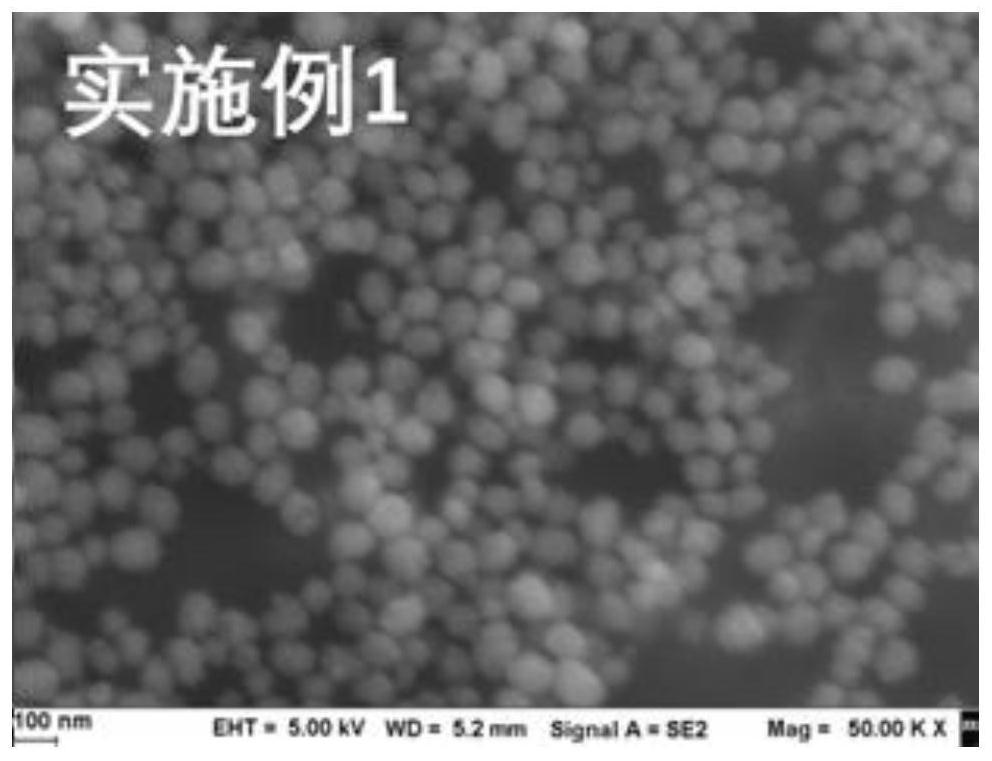

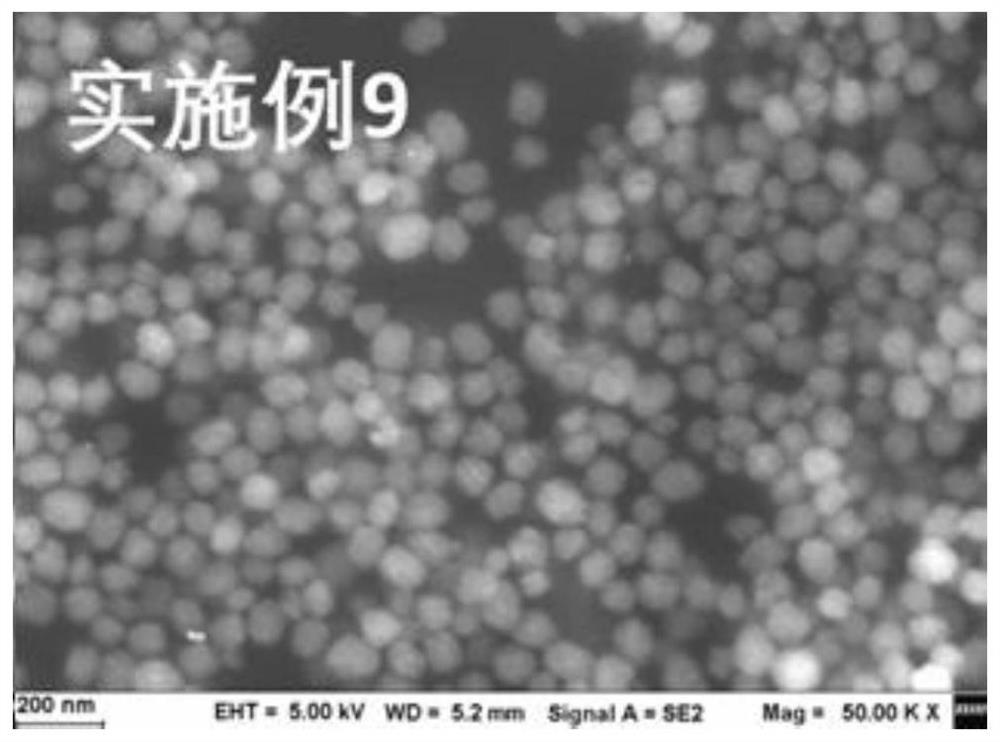

Embodiment 1

[0093] S1. Preparation of carrier Silicalite-1 (referred to as S-1)

[0094] Weigh tetrapropylammonium hydroxide, mix and stir with deionized water at room temperature for 10 minutes, then add tetraethyl orthosilicate dropwise, and age at room temperature for 6 hours. Transfer the obtained mixed solution to a crystallization kettle, crystallize at 100°C for 48h, then cool, centrifuge, wash, dry at 100°C for 10h, and then roast at 550°C for 6h to obtain Silicalite-1 molecular sieve. Wherein, the molar ratio of tetrapropylammonium hydroxide to tetraethyl orthosilicate=1:0.25, the amount ratio of tetraethyl orthosilicate to deionized water=0.25mol:1.5mol.

[0095] S2. Preparation of auxiliary agent-carrier S-1 complex

[0096] Disperse 2 g of the carrier Silicalite-1 in 5 mL of deionized water, add 0.186 g of magnesium nitrate, mix and stir for 6 h, then evaporate the resulting suspension to dryness at 80°C for 1 h, dry at 100°C for 12 h, and roast at 550°C for 6 h. Then the ob...

Embodiment 2

[0102] The preparation process of Example 1 was followed, except that 0.123 g of magnesium nitrate was replaced by 0.051 g of zirconyl nitrate to obtain catalyst 1Zr-Co / S-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com