Intelligent alarm bag type dust removing device

A technology of alarm bag and dust collector, which is applied in the field of intelligent alarm dust collector and bag filter, which can solve the problems of failure to find damaged cloth bags in time, excessive dust discharge, and penetration of dust particles, so as to avoid excessive dust discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

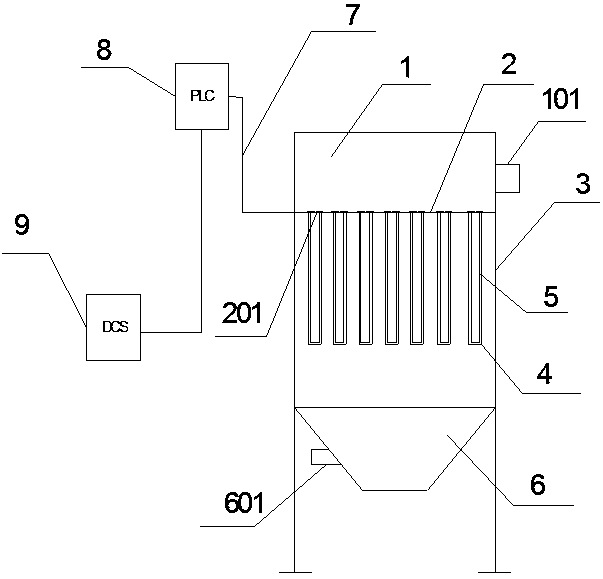

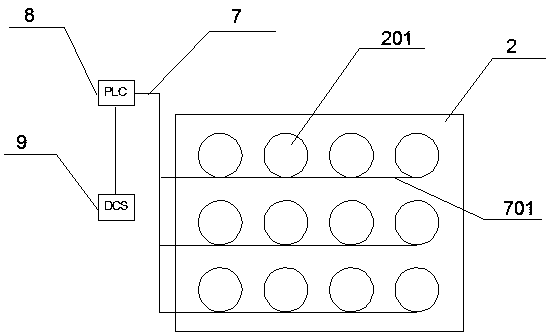

[0020] Such as Figure 1-4 As shown, an intelligent alarm bag filter includes an upper box 1, a flower plate 2, a middle box 3, a cloth bag 4, a bag cage 5, a lower box 6, a signal line 7, a PLC control cabinet 8 and a DCS system 9. There is a clean gas outlet 101 on one side of the upper box. The flower plate 2 is located between the upper box 1 and the middle box 3. There is a flower plate hole 201 on the flower plate 2. The cross section of the cloth bag 4 is circular. shape, hanging on the flower plate hole 201, the inside of the cloth bag 4 is supported by the bag cage 5, the lower box 6 is located at the lower part of the middle box 3, and has an air inlet 601;

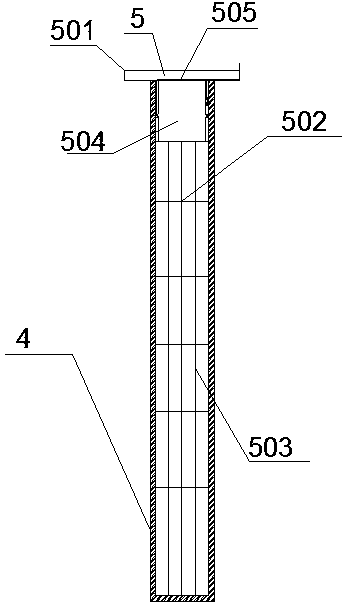

[0021] The top of the bag cage 5 is provided with a bag cage cap 501, longitudinally provided with longitudinal ribs 502, transversely provided with a reinforcing ring 503, the upper part is provided with a spray protection device 504 and a cloth bag performance monitoring system 505, and the spray protection de...

Embodiment 2

[0027] Such as Figure 1-4 As shown, an intelligent alarm bag filter includes an upper box 1, a flower plate 2, a middle box 3, a cloth bag 4, a bag cage 5, a lower box 6, a signal line 7, a PLC control cabinet 8 and a DCS system 9. There is a clean gas outlet 101 on one side of the upper box. The flower plate 2 is located between the upper box 1 and the middle box 3. There is a flower plate hole 201 on the flower plate 2. The cross section of the cloth bag 4 is circular. shape, hanging on the flower plate hole 201, the inside of the cloth bag 4 is supported by the bag cage 5, the lower box 6 is located at the lower part of the middle box 3, and has an air inlet 601;

[0028] The top of the bag cage 5 is provided with a bag cage cap 501, longitudinally provided with longitudinal ribs 502, transversely provided with a reinforcing ring 503, the upper part is provided with a spray protection device 504 and a cloth bag performance monitoring system 505, and the spray protection de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com