Frequent regeneration diagnosis method for diesel particle filter

A particle filter and diesel technology, which is applied in the diagnostic device of the exhaust treatment device, the machine/engine, the electronic control of the exhaust treatment device, etc. Problems such as insignificant changes in pressure difference, to achieve the effect of avoiding excessive discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the various figures of the application, structurally identical or functionally similar features are indicated by the same reference numerals.

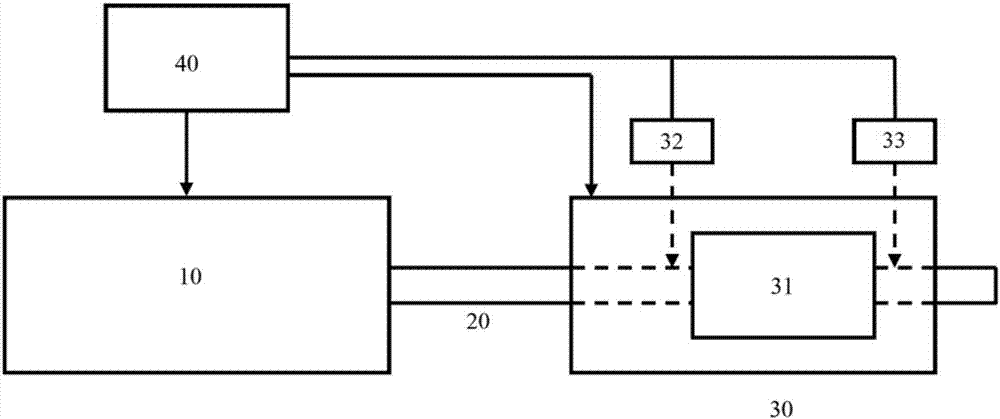

[0025] figure 1 A schematic block diagram of an engine and exhaust emission treatment system is briefly shown. After the diesel engine 10 of the diesel vehicle is started, the exhaust gas passes through the exhaust pipe 20 to the exhaust emission treatment system 30 . The exhaust emission treatment system 30 includes a diesel particulate filter 31 for filtering particulate matter in the exhaust gas. The filtered exhaust gas is discharged to the outside of the diesel vehicle through the exhaust pipe 20 passing through the exhaust emission treatment system 30 . Pressure sensors 32 and 33 are respectively arranged at both ends of the inlet and outlet of the diesel particulate filter 31 for detecting the exhaust pressure at the inlet and the outlet. The control unit 40 (such as the ECU of the diesel vehicle) obtains the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com