Regenerating method of catalytic conversion catalyst

A catalytic conversion and catalyst technology, applied in the direction of catalyst regeneration/reactivation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of poor performance of catalyst flow rate modulation, high frequency of catalyst regeneration, etc. problem, achieve the effect of reducing the frequency of charcoal regeneration and avoiding the loss of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

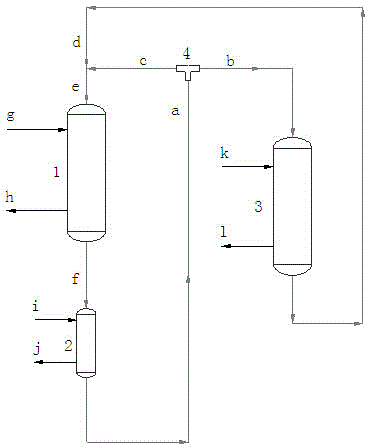

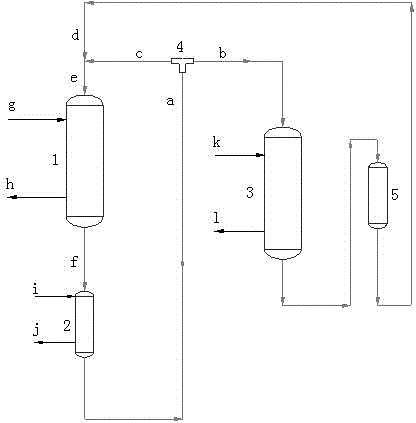

[0028] The catalyst f removed from the reactor 1 first enters the first regenerator 2 and is purged and regenerated by the first regeneration gas i at 170 °C. The residence time of the catalyst in the first regenerator 2 is τ 2 is catalyst residence time τ in reactor 1 1 10 times. The primary regenerant a at the outlet of the first regenerator 2 is sent to the catalyst flow distributor 4 and then divided into two streams of b and c, which enter the second regenerator 3 and reactor 1 respectively, and the primary regenerant flow entering the reactor 1 The flow of stream c accounts for 1% of the total flow of the first-stage regenerant in stream a, and the first-stage regenerant in stream b enters the second regenerator 3 for secondary regeneration through the second regeneration gas k. The regenerant d and the primary regenerant stream c are combined and enter the reactor 1 together.

[0029] The reactor 1, the first regenerator 2 and the second regenerator 3 are in the form ...

Embodiment 2

[0036] The catalyst f removed from the reactor 1 first enters the first regenerator 2 and is purged and regenerated by the first regeneration gas i at 650 °C. The residence time of the catalyst in the first regenerator 2 is τ 2 is catalyst residence time τ in reactor 1 1 5 times. The primary regenerant a at the outlet of the first regenerator 2 is sent to the catalyst flow distributor 4 and then divided into two streams of b and c, which enter the second regenerator 3 and reactor 1 respectively, and the primary regenerant flow entering the reactor 1 The flow of stream c accounts for 60% of the total flow of the first-stage regenerant in stream a, and the first-stage regenerant in stream b enters the second regenerator 3 for secondary regeneration through the second regeneration gas k. The regenerant d and the primary regenerant stream c are combined and enter the reactor 1 together.

[0037] The reactor 1, the first regenerator 2 and the second regenerator 3 are in the form ...

Embodiment 3

[0044] The catalyst f removed from the reactor 1 first enters the first regenerator 2 and is purged and regenerated by the first regeneration gas i at 300 °C. The residence time of the catalyst in the first regenerator 2 is τ 2 is catalyst residence time τ in reactor 1 1 0.1 times. The primary regenerant a at the outlet of the first regenerator 2 is sent to the catalyst flow distributor 4 and then divided into two streams b and c, which enter the second regenerator 3 and reactor 1 respectively, and the primary regenerant flow entering the reactor 1 The flow of stream c accounts for 100% of the total flow of the first-stage regenerant in stream a, and the first-stage regenerant in stream b enters the second regenerator 3 for secondary regeneration through the second regeneration gas k. The regenerant d and the primary regenerant stream c are combined and enter the reactor 1 together.

[0045] The reactor 1, the first regenerator 2 and the second regenerator 3 are in the form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com