Method for selecting model of electrostatic dust collector for deeply cooling flue gas

An electrostatic precipitator and electrostatic precipitator technology, applied in electrostatic separation and other directions, can solve the problems of inability to accurately select an electrostatic precipitator, waste, and small design, and achieve the effect of avoiding excessive dust discharge at the outlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The embodiments of the present invention are described in detail below, and are intended to be used to explain the present invention, but should not be construed as a limitation of the present invention.

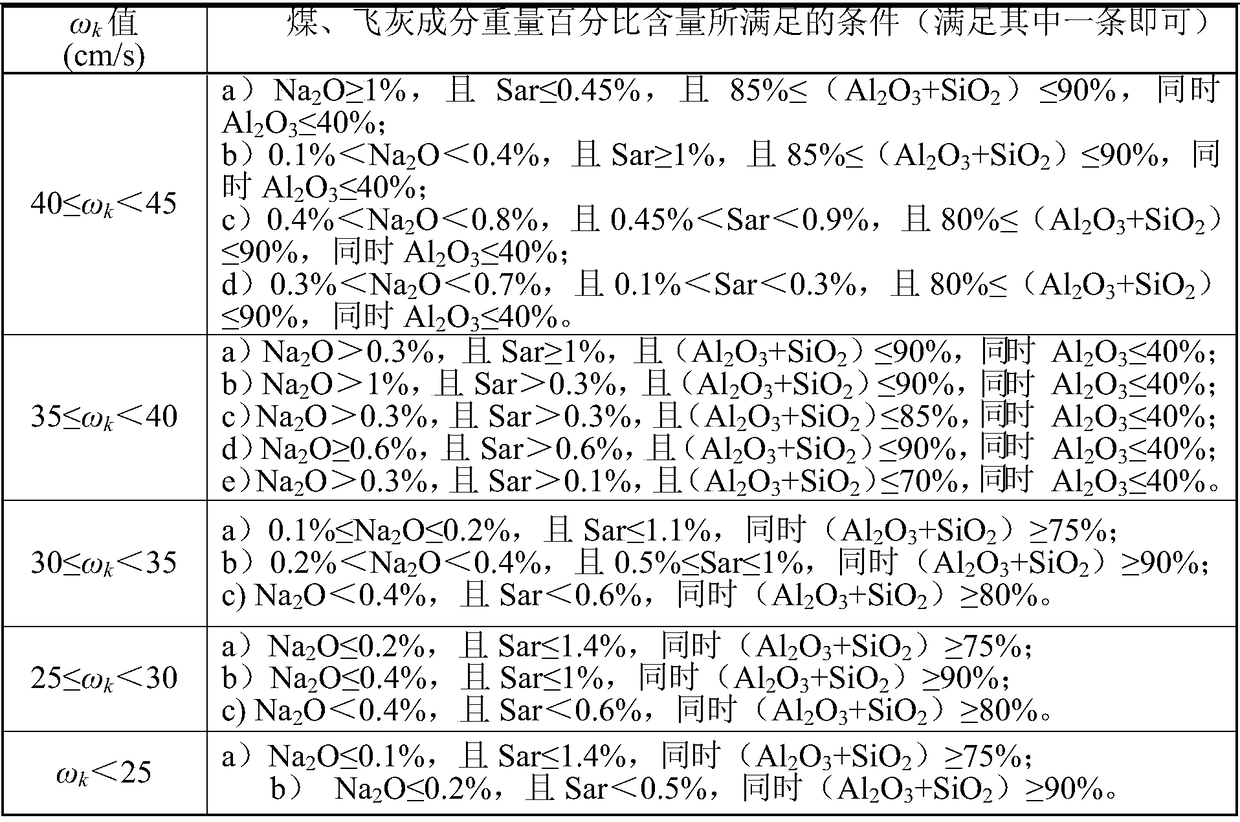

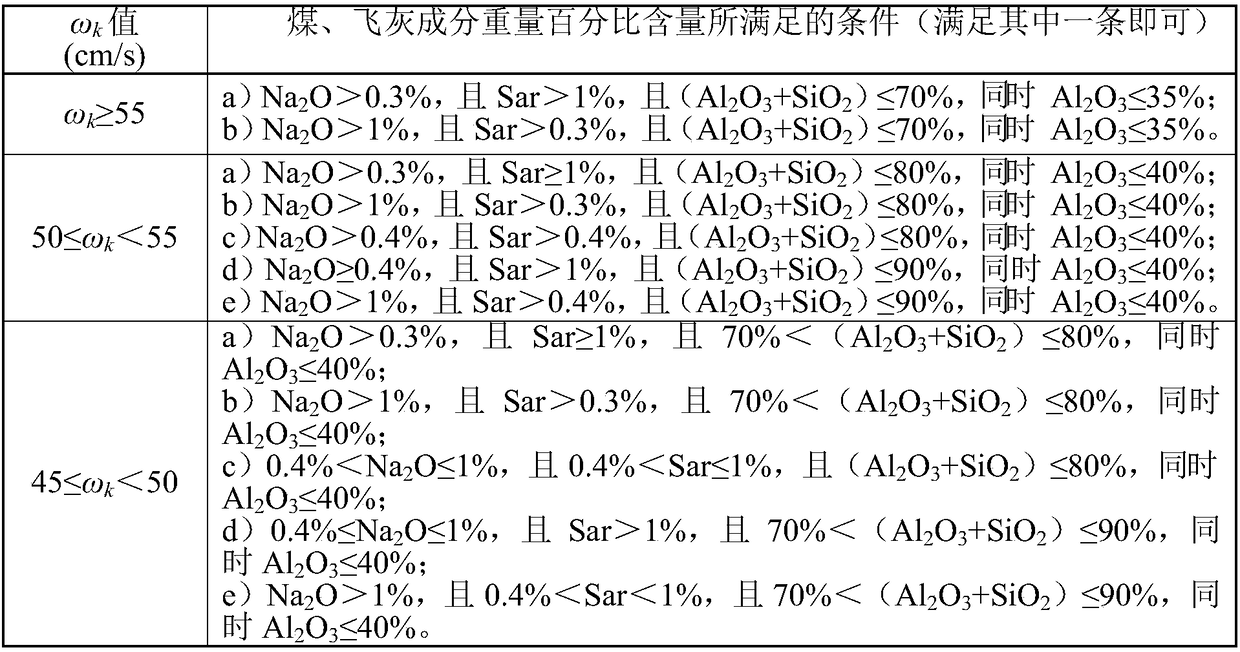

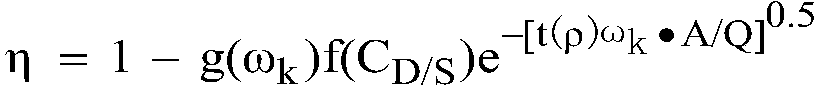

[0061] The following is a new unit of 2*1000MW in a power plant. According to the requirements of local environmental protection policies and the overall setting of the pollutant removal system after the power plant, the smoke and dust at the chimney outlet must be controlled at 5mg / Nm 3 and below, the smoke and dust at the outlet of the electrostatic precipitator shall be controlled at 15mg / Nm 3 and below (guaranteed if a power supply partition stops working). The main design coal and ash components of this project are shown in the table, and the flue gas parameters and performance requirements at the inlet of the electrostatic precipitator for deep cooling of flue gas are shown in the table below.

[0062]

[0063]

[0064] Main coal and ash composition table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com