Method for low-temperature catalytic ozone treatment of high-humidity organic waste gas

A technology for organic waste gas and ozone treatment, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve the problems of excessive ozone emission, low catalytic efficiency, easy deactivation of catalysts, etc., to save energy consumption and avoid excessive emissions. , the effect of improving the catalytic degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

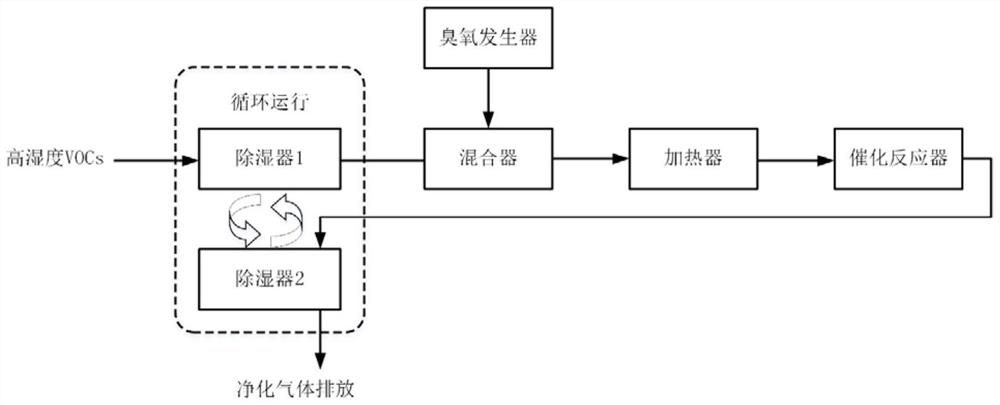

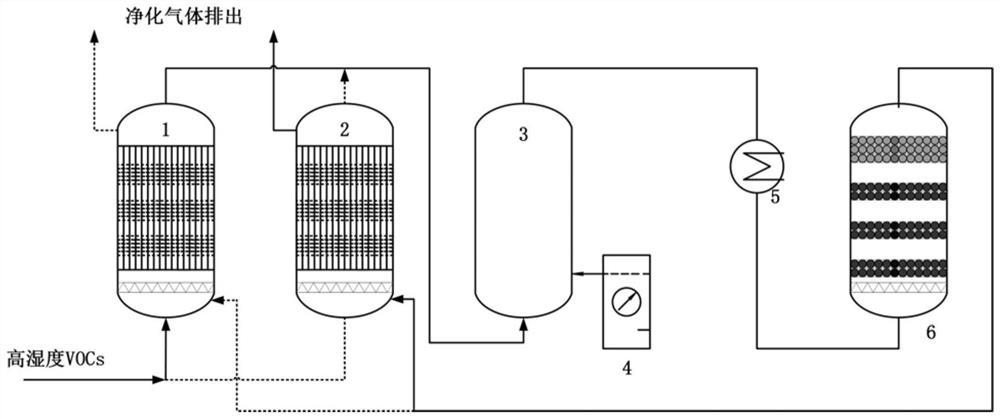

[0029] like Figure 1~2 , a purification system for ozone catalytic treatment of organic waste gas for treating chlorobenzene-containing waste gas in sewage plants, the system includes a first dehumidification adsorption tower 1 and a second dehumidification adsorption tower 2; the first dehumidification adsorption tower 1 and the second dehumidification adsorption tower The bottom of the second dehumidification adsorption tower 2 is provided with an air inlet, and the output ends at the top of the first dehumidification adsorption tower 1 and the second dehumidification adsorption tower 2 are connected with the bottom of the gas mixer 3, the heater 5 and the fixed bed catalytic reactor 6 successively. The output end on the top of the fixed bed catalytic reactor 6 is connected to the bottom input end of the first dehumidification adsorption tower 1 and the second dehumidification adsorption tower 2, and the output end on the top of the first dehumidification adsorption tower 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com