Evaporation treatment method for radioactive waste liquids of nuclear power plant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

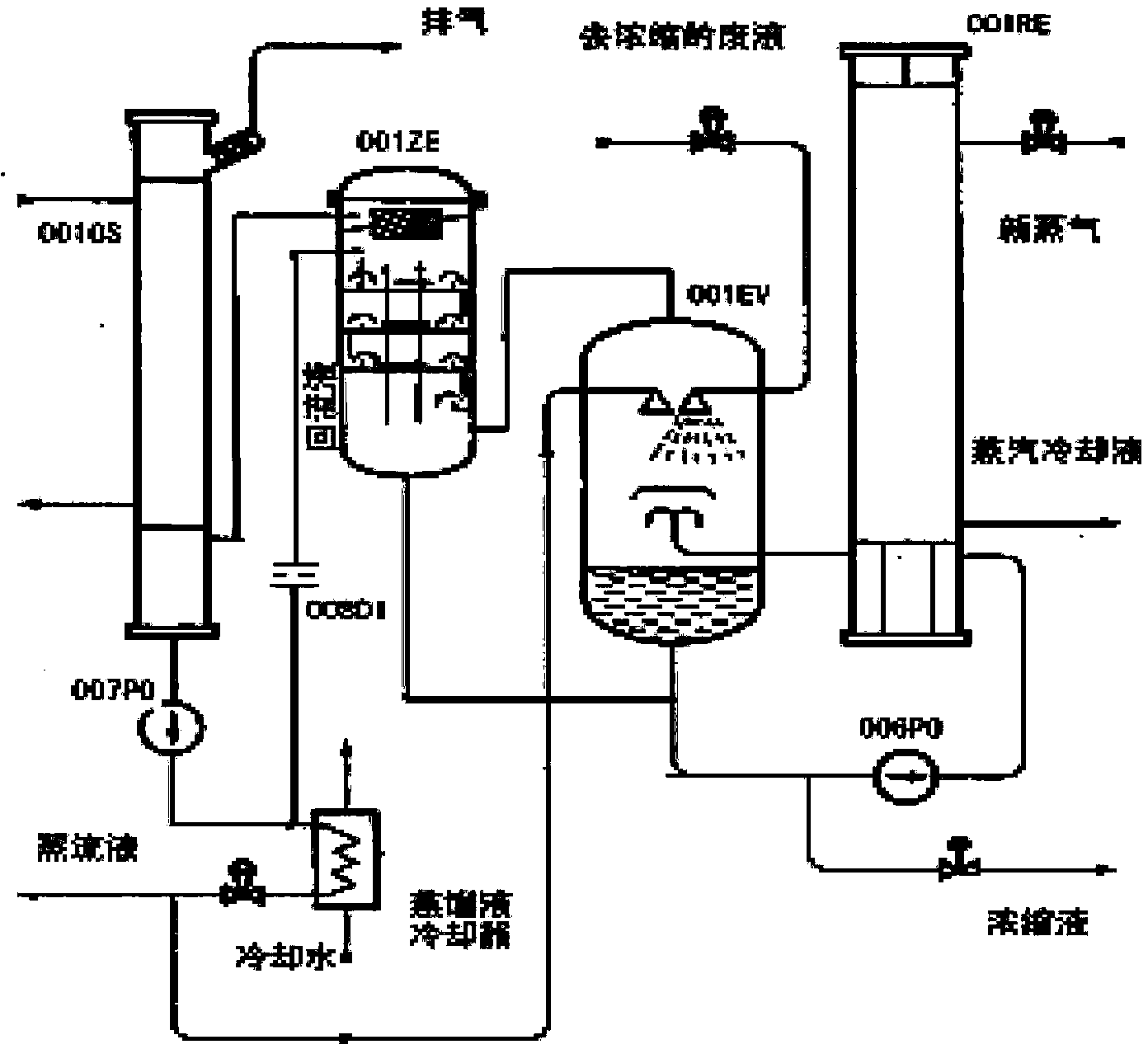

Method used

Image

Examples

Embodiment 1

[0059] Embodiment 1. A method for evaporating radioactive waste liquid from a nuclear power plant, preferably comprising the following steps:

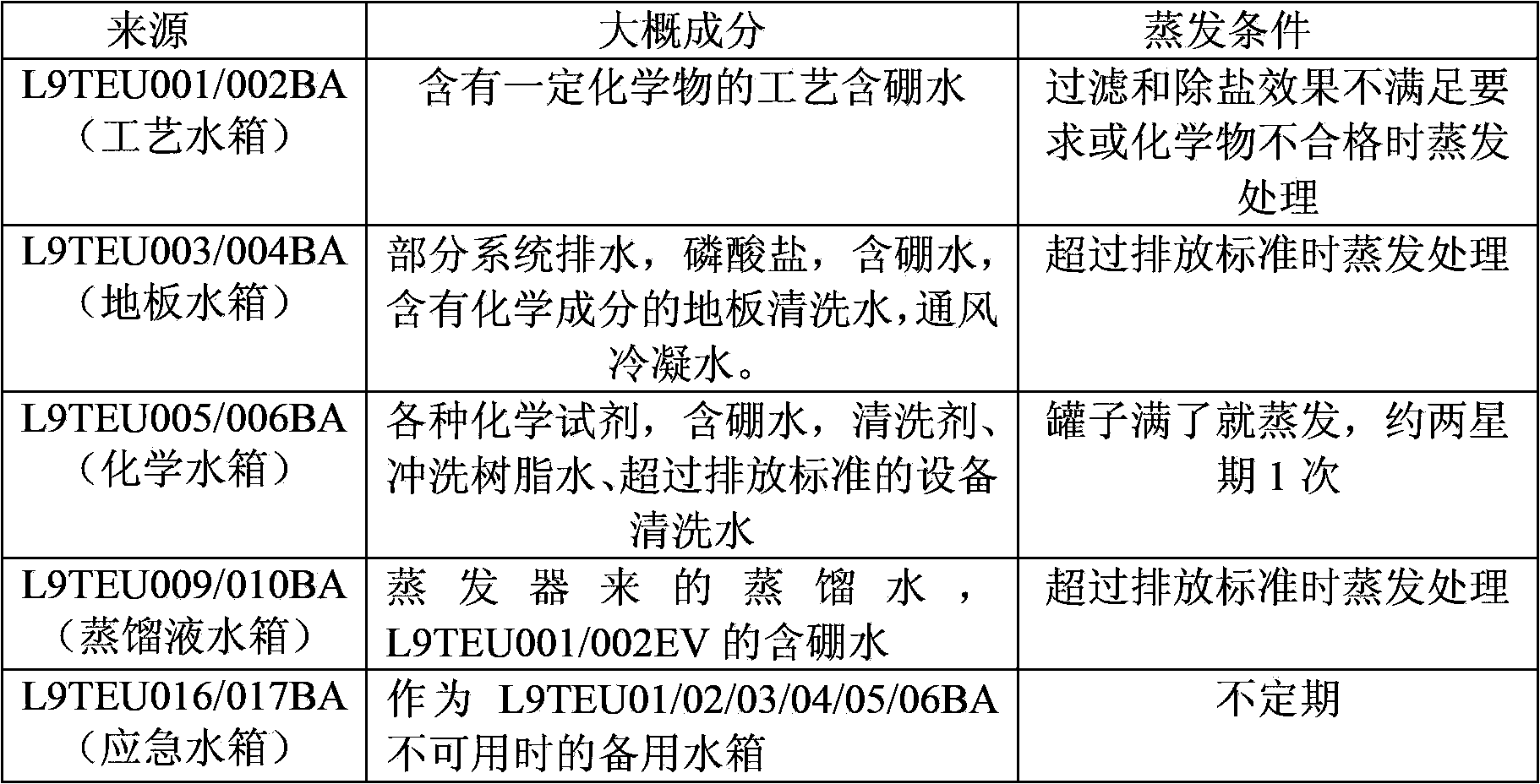

[0060] (1) First, collect all kinds of non-reusable radioactive waste liquid formed by the nuclear power plant in the corresponding front waste liquid tank;

[0061] (2) The waste liquid in the front waste liquid tank is transported to the evaporator for evaporation treatment, and the evaporated steam is sent to the condenser to condense to form a distillate, which is left in the evaporator as a concentrated liquid, and the radioactivity of the distillate is detected; In the above step (2), the radioactive detection frequency of the distillate is sampling and detection before each discharge of the distillate.

[0062] (3) Detect that the radioactivity of the distillate is lower than 0.5MBq / m 3 Discharge the distillate; detect that the radioactive activity of the distillate is equal to or higher than 0.5MBq / m 3 , and the concentration...

Embodiment 2

[0066] Embodiment 2. The following is the application of the present invention to the evaporation of waste liquid in Ling Ao Phase I nuclear power plant.

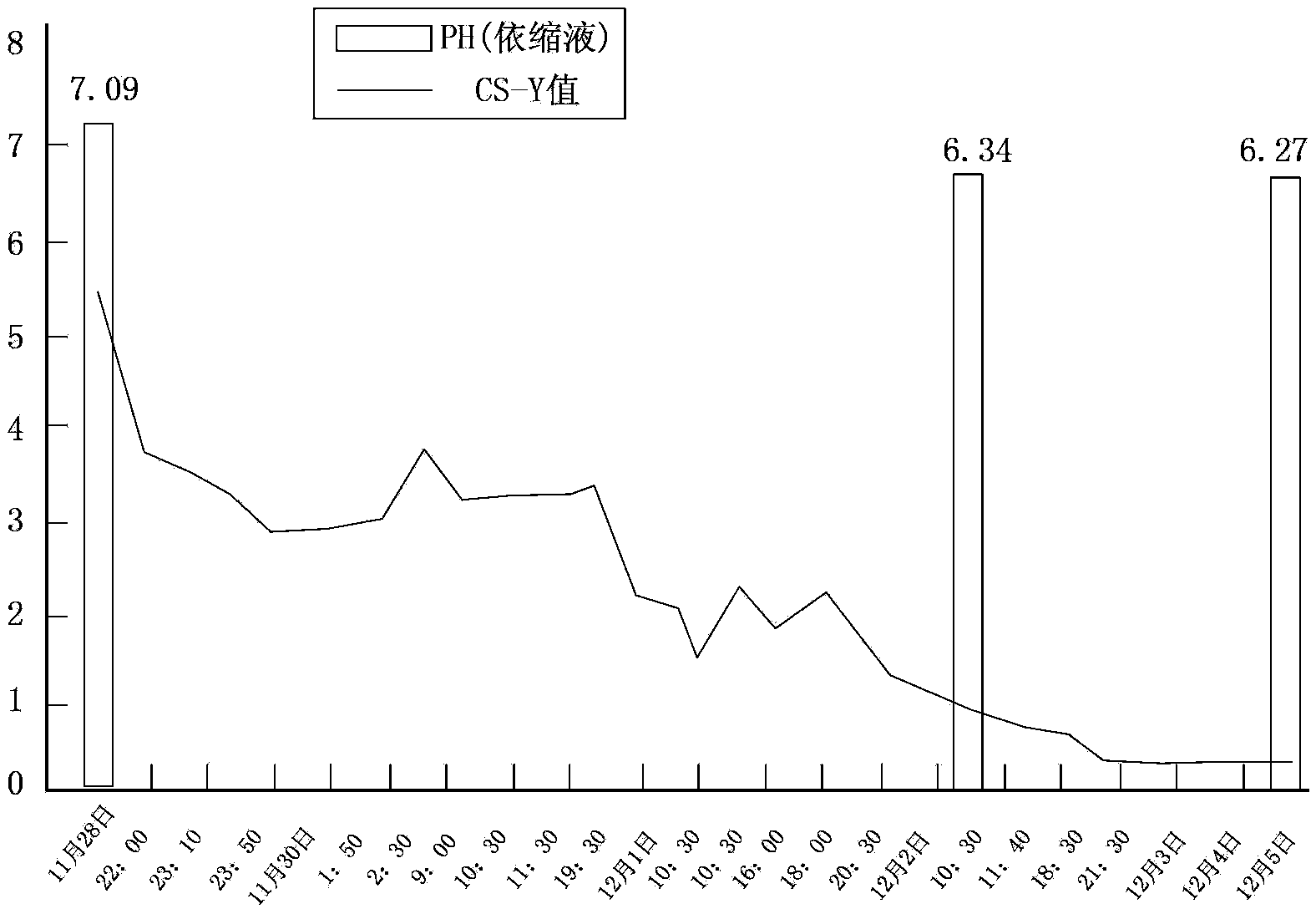

[0067] 1. On November 9, the efficiency of the waste liquid evaporation unit (L9TEU) of the Ling Ao Phase I nuclear power plant was low. During the treatment process using conventional methods, it was found that a large amount of foam was generated when the condenser CS was sampled, so it was suspected that the low efficiency was related to the excessive foam of the waste liquid in the evaporator EV. At the same time, in the investigation of the relevant evaporation activities since 2007 It was found that after adding alkali to the evaporator EV and adjusting the Na / B concentration of the evaporator EV concentrate, the efficiency of the evaporator EV would exceed the internal control standard. The pH value of the liquid is 8.5, which is higher than 6.3 in the Daya Bay Nuclear Power Plant. After testing, it was confirmed tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com