Ferric phosphate wastewater treatment process and treatment device

A treatment process, iron phosphate technology, applied in water/sewage treatment, heating water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problem of incomplete and effective blocking of ammonia nitrogen, inability to meet reuse standards, ammonium ion Low interception rate and other issues, to achieve the effect of eliminating excessive ammonia nitrogen discharge, less impurities, and high recovery value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

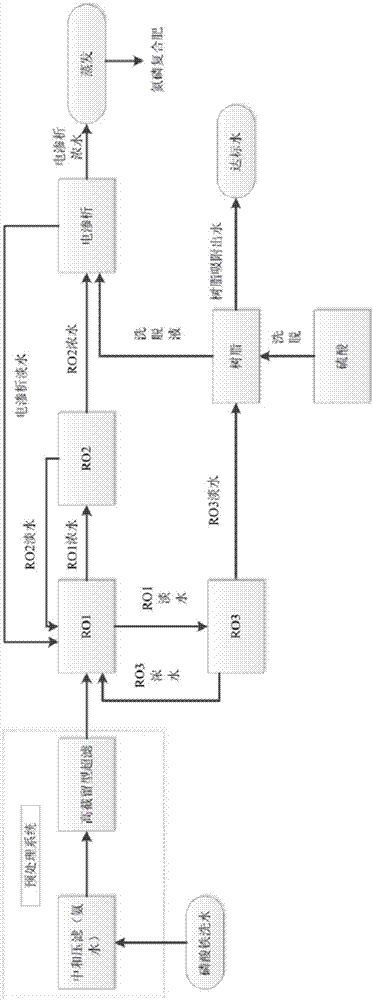

Method used

Image

Examples

Embodiment 1

[0076] Ferric phosphate wastewater comes from ferric phosphate reaction tank cleaning solution, NH 4 + : 4000mg / L, SO 4 2- : 9000mg / L, PO 4 3- : 450mg / L, TDS: 1.45%.

[0077] The treatment process is as follows:

[0078] (1) Adjust the pH of ferric phosphate wastewater to 6.5 with ammonia water, press filter to remove suspended particles, the SS of the filtrate is less than 5mg / L, adjust the temperature of the filtrate to below 40°C and pass through a high cut-off ultrafiltration membrane to obtain ultrafiltration Effluent, ultrafiltration effluent SDI4 + : 5800mg / L, SO 4 2- : 8000mg / L, PO 4 3- : 450mg / L, TDS: 1.49%.

[0079] (2-1) The ultrafiltration effluent passes through the first-stage security filter and then enters the first-stage reverse osmosis device for the first-stage reverse osmosis.

[0080] Based on the water inflow, add 2ppm each of antiscalant, bactericide and reducing agent to the influent of the first-stage reverse osmosis, the recovery rate of t...

Embodiment 2

[0094] Ferric phosphate wastewater comes from the cleaning solution of ferric phosphate reaction tank, its pH=5, where NH 4 + : 2100mg / L, SO 4 2- : 5000mg / L, PO 4 3- : 266mg / L, TDS: 0.75%.

[0095] The treatment process is as follows:

[0096] (1) Adjust the pH of iron phosphate wastewater to 6.5 with liquid ammonia, press filter to remove suspended particles, the SS of the filtrate is less than 5mg / L, adjust the temperature of the filtrate to below 40°C, and pass through a high cut-off ultrafiltration membrane to obtain an ultrafiltration membrane. Filter out the water, the SDI of the ultrafiltered water is less than 5, NH 4 + : 2900mg / L, SO 4 2- : 5000mg / L, PO 4 3- : 266mg / L, TDS: 0.75%.

[0097] After passing through the first-stage security filter, it enters the first-stage reverse osmosis device for the first-stage reverse osmosis.

[0098] Based on the water inflow, add 2ppm each of antiscalant, bactericide and reducing agent to the influent of the first-sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com