Online broken bag blocking device for pulse jet bag type dust collector

A bag-type dust collector and plugging device technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of difficult replacement of filter bags, excessive discharge of dust collectors, and failure of filter bags. , to shorten the time of online maintenance, prevent excessive discharge, and maintain normal work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

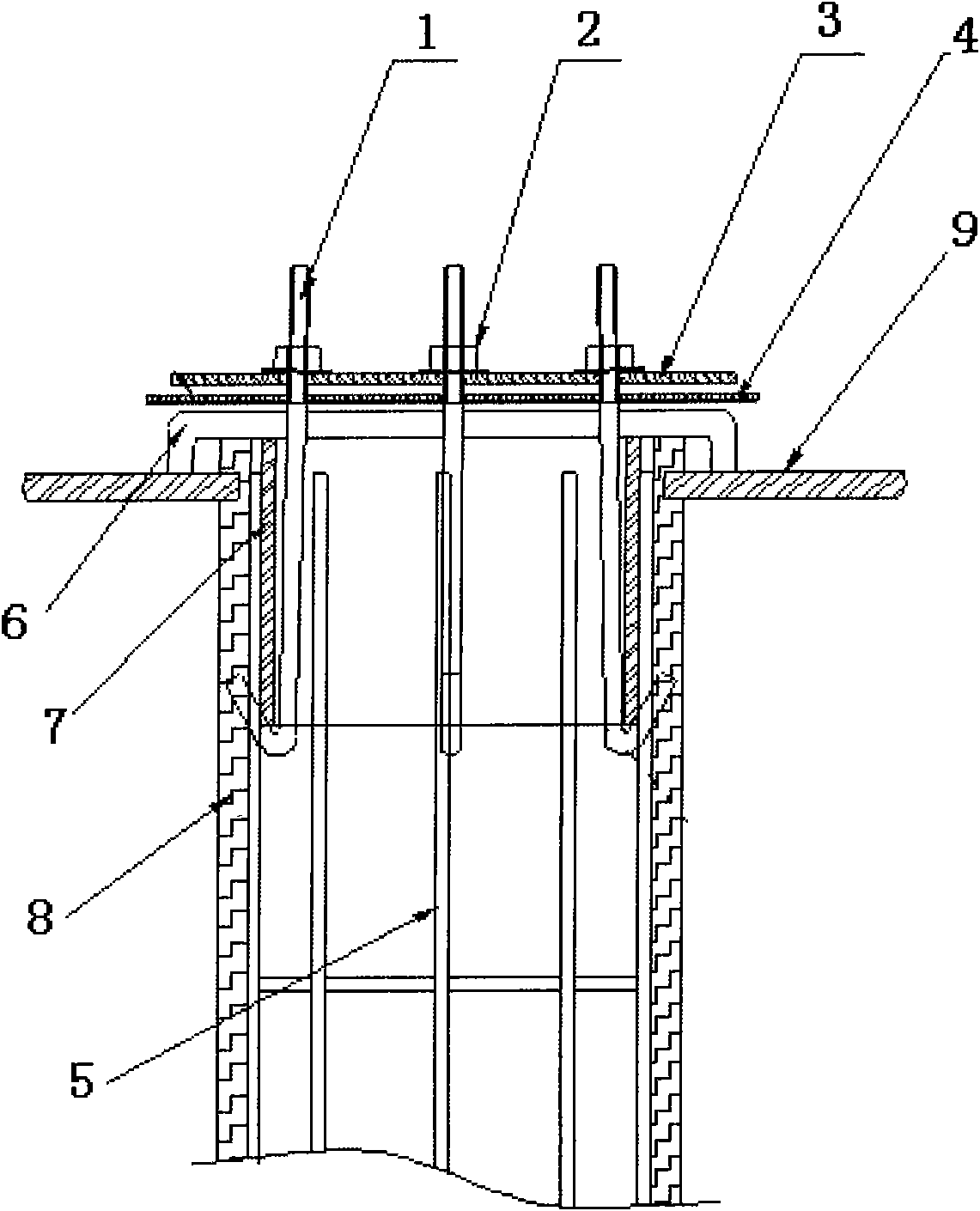

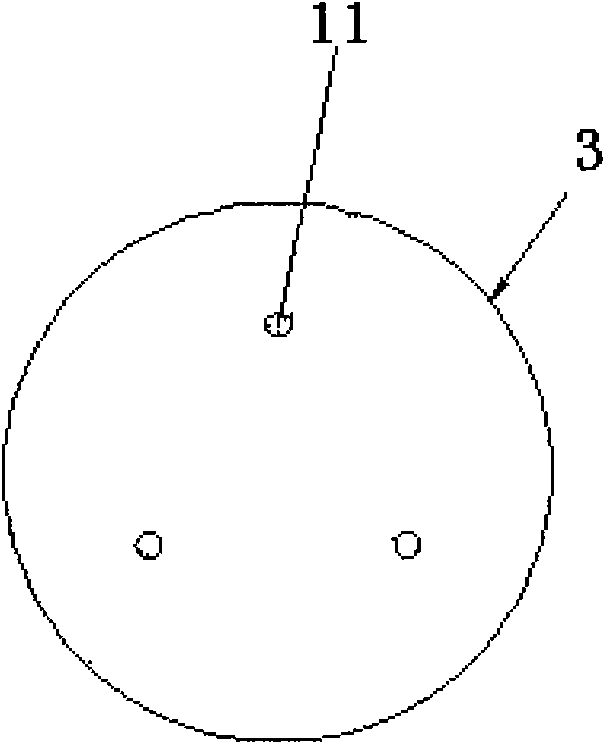

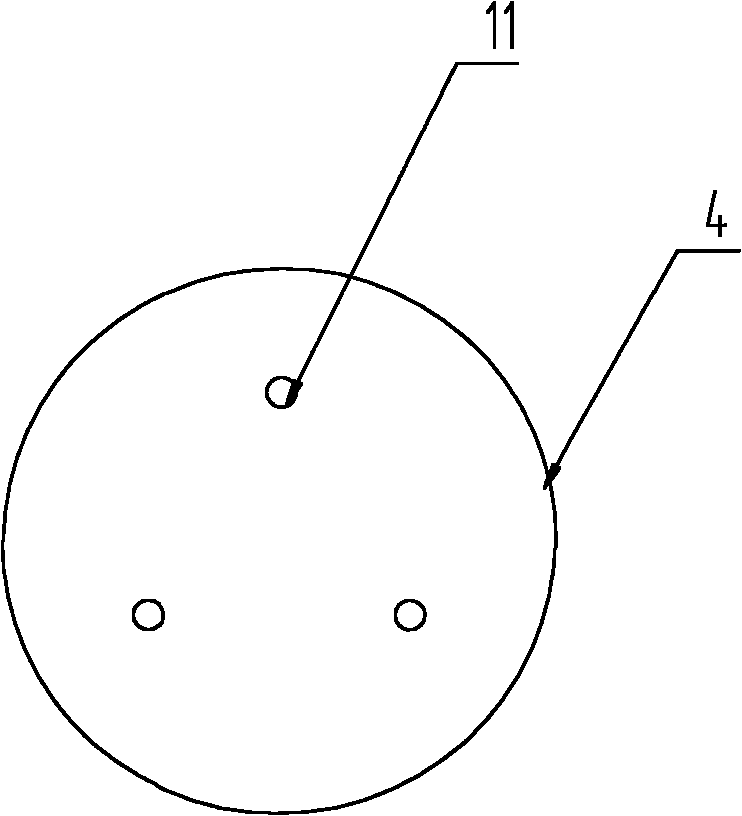

[0021] An online bag-breaking device for a pulse-jet bag-type dust collector, comprising a sealing plate 3 and a gasket 4 superimposed on each other, the gasket 4 is provided with a central hole 10, and the sealing plate 3 is provided with a hole There are three ring-shaped installation holes 11 distributed around; it includes three screw rods 1 with hooks at the lower ends, and each screw rod 1 passes through the central hole 10 on the gasket 4 from the lower side of the gasket 4 and corresponds to the sealing plate 3. Stretch out the sealing plate 3 behind the mounting hole 11 of each screw rod 1, and the stretching end of each screw rod 1 is all screwed with a nut 2.

[0022] The pulse-jet bag-type dust collector includes a flower plate 9 and a bag cage 5. The flower plate 9 is provided with a plurality of flower plate holes, and a filter bag 8 is installed on the flower plate 9 corresponding to each flower plate hole. The bag cage includes a bag cage skeleton 5, the annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com