Coal-fired power plant fly ash rapid quantitative loading station and method

A technology of coal-fired power plants and fly ash, which is applied in the field of automatic mechanical devices and bulk cargo loading to achieve the effects of promoting flow, improving wear resistance, and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

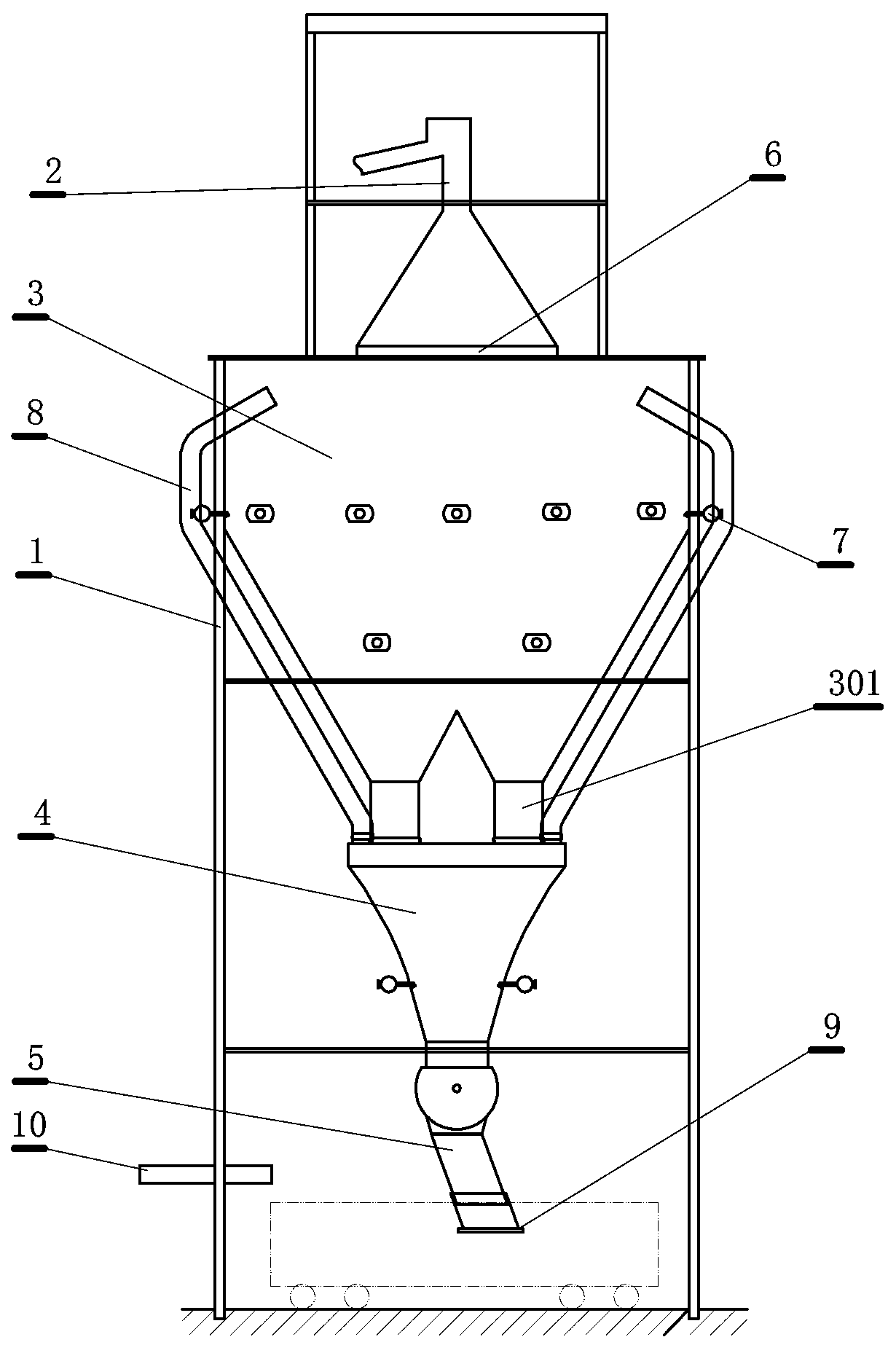

[0024] This embodiment is a fast quantitative loading station for fly ash of a coal-fired power plant, such as figure 1 shown. The present embodiment comprises: frame 1, described frame is provided with conveyer belt head 2, buffer bin 3, quantitative bin 4, swing chute 5 sequentially from top to bottom, described conveyor belt head, buffer bin, quantitative bin and A sealing facility 6 is provided between the swinging chutes, and the buffer bin is provided with at least four outlets 301, and the weighing bin body of the weighing bin is inwardly curved, and is lined with a polyurethane liner. At least one layer of air cannons 7 are evenly distributed around the surrounding walls of the buffer storehouse and the quantitative storehouse, and the nozzles of each air cannon are arranged downward along the storehouse wall. The quantitative storehouse is provided with at least two ventilation pipes 8, so One end of the ventilation pipe is arranged on the top of the quantitative war...

Embodiment 2

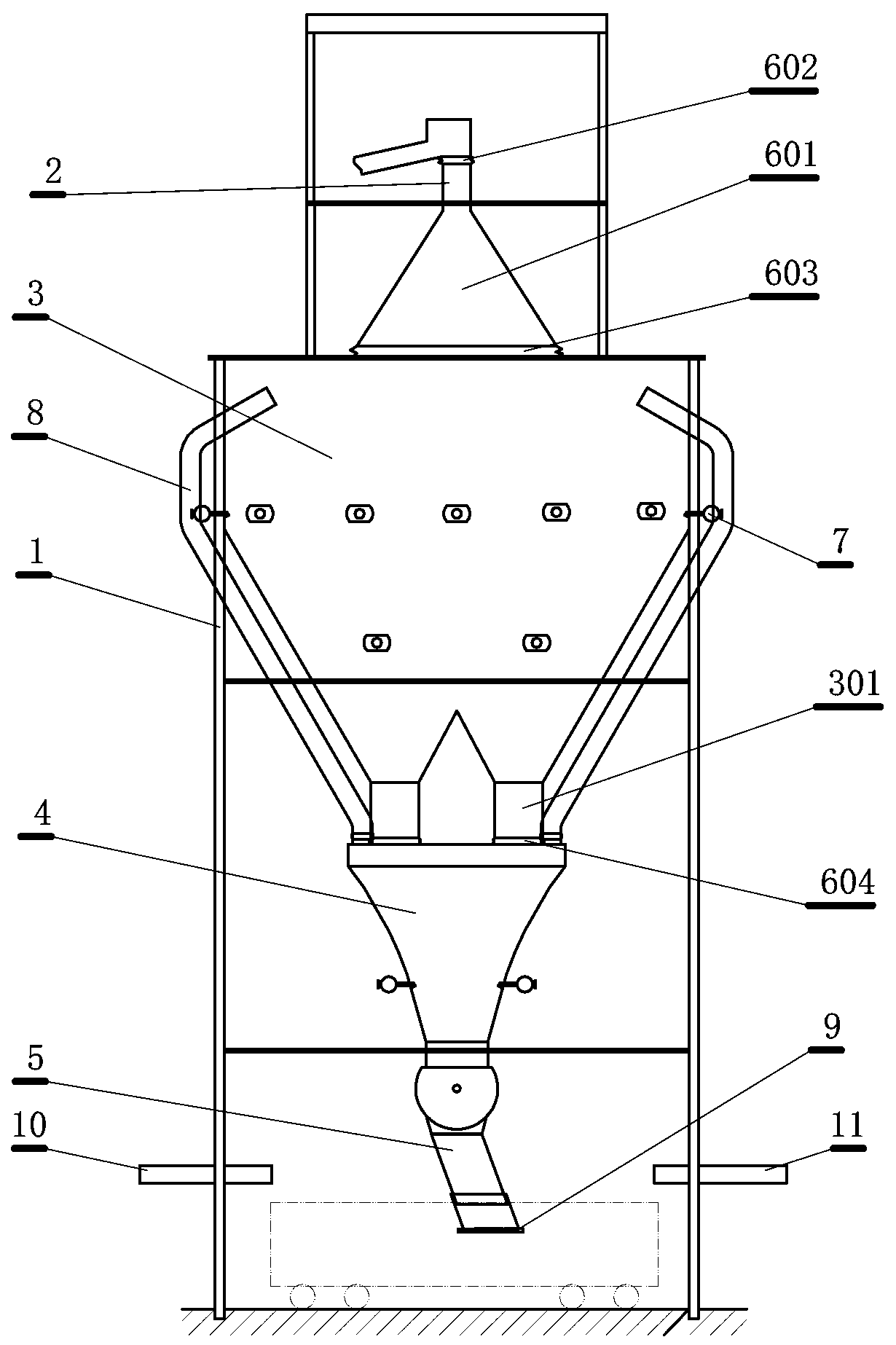

[0042] This embodiment is an improvement of the first embodiment, and is a refinement of the first embodiment on the sealing facilities. The sealing facility described in this embodiment is that a flexible connection sealing cover is provided between the conveyor belt machine head and the buffer bin, between the buffer bin and the quantitative bin, between the quantitative bin and the swing chute, and the buffer bin and the quantitative bin Use a gasket seal on the setting gate.

[0043] The sealing facility is a system, distributed in multiple parts of the loading station, mainly composed of various baffles, maintenance structures, seals, etc.

[0044] Between the head of the conveyor belt and the buffer warehouse, the head guard plate 601 (such as figure 2 As shown) seal the conveyor belt head and the feed inlet of the buffer bin in a narrow space that only allows the material to go from the conveyor belt to the buffer bin inlet, so as to avoid the scattering and diffusion...

Embodiment 3

[0049] This embodiment is an improvement of the first embodiment, and is a refinement of the first embodiment on the buffer gate. Each discharge port of the buffer bin described in this embodiment is respectively provided with a double-wing gate with a stainless steel and rubber seal dust-proof design. Lubricate wear-resistant slides.

[0050] The split double-wing gate is easy to seal and has a fast opening and closing speed, especially suitable for bulk materials with fine particles. The gate is dust-proof with stainless steel and rubber seal. The upper surface of the gate is covered with a thick 10mm wear-resistant plate to prolong the service life. The lower part is equipped with a high-strength non-lubricating wear-resistant slider, which does not need to install an automatic lubrication device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com