Saggar for roasting electronic elements and electronic materials

A technology for electronic materials and electronic components, applied in the field of refractory material containers, can solve the problems of affecting product performance, uneven heating of saggars, cracking of saggars, etc., to achieve smooth bottom airflow, uniform heating and cooling atmosphere, and reduce cracking.

Inactive Publication Date: 2012-06-27

江苏三恒高技术窑具有限公司

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The kiln furniture saggers currently used in China are all flat-bottomed structures, such as Chinese patent application 2011200956816. The kiln furniture saggers are placed on the setter or push plate, and the saggers will be heated unevenly in the high-temperature firing environment, which will affect product performance. At the same time, the sagger will crack due to uneven heating and cooling

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

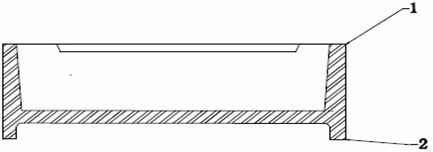

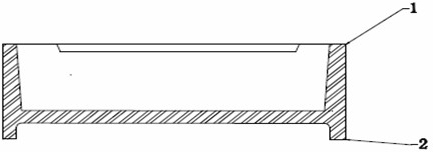

[0007] A sagger for firing electronic components and electronic materials, comprising a sagger body 1, the bottom of the sagger body can be provided with support feet 2 at the four corners or on the four sides or other parts of the bottom, and the support feet 2 and the sagger body 1 One-piece structure, the height of the legs is designed between 1-50 mm.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A saggar for roasting electronic elements and electronic materials belongs to a container made of refractory materials and comprises a saggar body. Supporting lugs are disposed at the bottom of the saggar body, so that when used in a kiln, the saggar is heated and cooled uniformly, airflow at the bottom of the saggar is smooth, influence of contact stress concentration between the saggar and a push plate is low, possibility of crack of the bottom of the saggar is reduced, the service life of the saggar is prolonged, and service cost is lowered.

Description

technical field [0001] The invention belongs to a refractory material container, in particular to a sagger used for roasting electronic components and electronic materials. Background technique [0002] Electronic components and electronic materials are the foundation of the electronic information industry. Domestically produced kilns are mainly high-temperature kilns. The firing of electronic components and electronic materials requires high technical requirements for the use of kiln furniture. The uneven firing atmosphere at high temperature will affect the quality of electronic components and affect the performance of electronic materials. The kiln furniture saggers currently used in China are all flat-bottomed structures, such as Chinese patent application 2011200956816. The kiln furniture saggers are placed on the setter or push plate, and the saggers will be heated unevenly in the high-temperature firing environment, which will affect product performance. , At the sam...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F27D5/00

Inventor 王立平

Owner 江苏三恒高技术窑具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com