Support body for Jun porcelain firing

A technology of jun porcelain and support body, applied in the furnace, charge composition/state, charge and other directions, can solve the problems of large thermal stress, damage to the support body, cracks of the support body, etc., to reduce cracks, reduce use costs, and smooth bottom airflow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

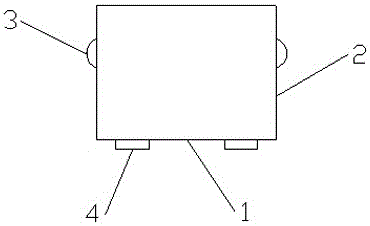

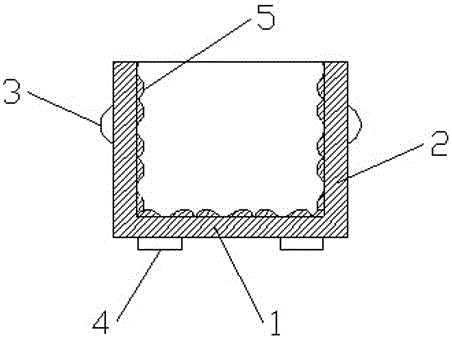

[0010] Such as figure 1 , 2 As shown, a Jun porcelain firing support body includes a support base 1, a support wall 2 is provided on the support base 1, a support foot 4 is evenly provided at the bottom of the support base 1, and a bracelet is provided on the support wall 2 3. Both the bottom 1 and the inner wall of the support wall 2 are provided with wave patterns 5 . The shape of the support base 1 is rectangle, square or circle.

[0011] When the present invention is used specifically: the support body is set as the upper opening, and the support body is made of refractory material. The Jun porcelain body is placed in the holder body, the setting of the bracelet 3 facilitates the lifting of the holder body, and the setting of the supporting feet 4 ensures that the holder body is placed stably and firmly. The invention improves the structure of the bottom of the support body and the support wall, so that when the support body is used in a kiln, the atmosphere is evenly h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com