Thermogravimetric apparatus for measuring volatile and easily condensed products in reaction process

A reaction process and product technology, applied in the field of analytical instruments, can solve the problems of inability to monitor volatile and easily condensed products, and achieve the effects of convenient operation and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

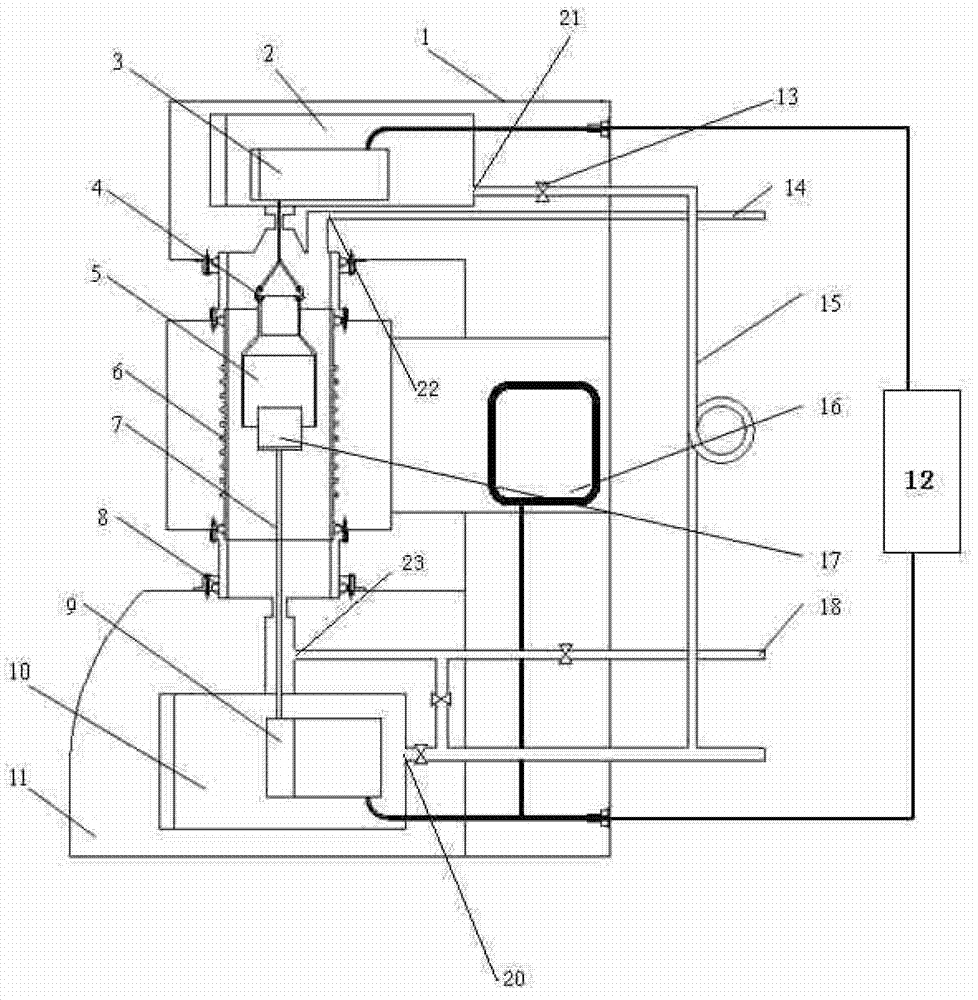

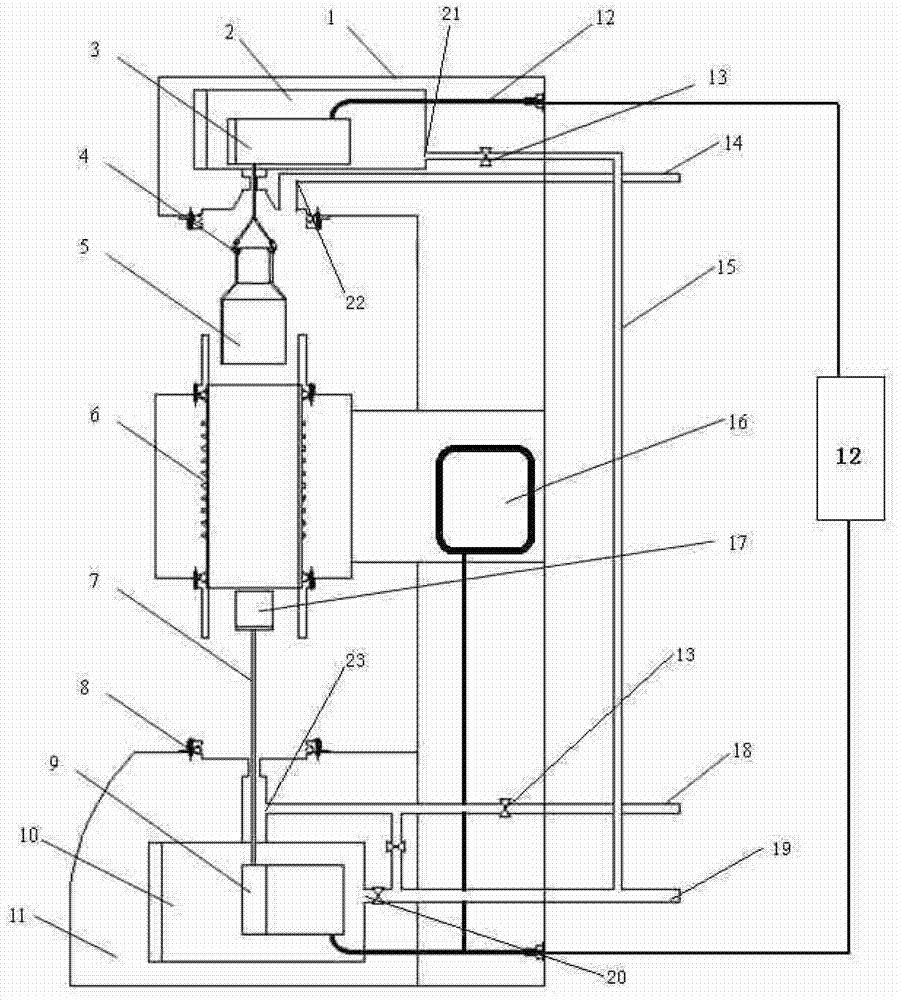

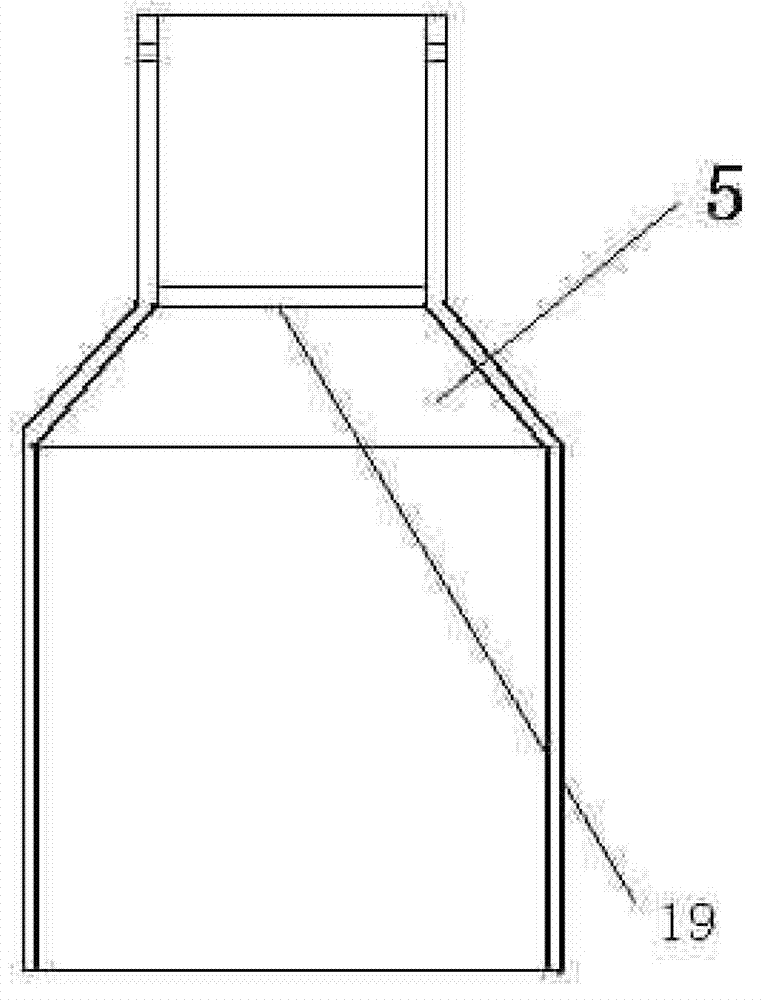

[0031] Turn on the power of the thermogravimetric device capable of measuring volatile substances, and control the opening of the lifting device 6 through the data acquisition console 12, so that the device rises to figure 2 In the position shown, the crucible 17 with the reactant sample is placed on the reactant support rod 7, the collection cup 5 is hung on the lower part of the upper microbalance 3 through the hook 4, and then the device is lowered to figure 1 The shown position makes the upper and lower ends of the heating furnace 6 enter the corresponding sealing ring 8 to seal the furnace. Upward measurement chamber 2 and lower measurement chamber 11 through protective gas inlet pipe 15, respectively feed 20ml / min high-purity argon gas; 40ml / min high-purity argon gas is passed into heating furnace 6 through reaction gas inlet pipe 18; data acquisition The console 12 sets the heating program, and the program is opened with 20 oC / min to raise the temperature to the set t...

Embodiment 2

[0033] In this embodiment, the device of the present invention is used. The inner diameter of heating furnace 6 is 30mm, and the working temperature range is 0~1600 o c. According to the above-mentioned working process, put the crucible 17 that fills the silicon nitride powder on the support rod in the thermogravimetric furnace, and feed 40ml / min high-purity argon into the upper measurement chamber 2 and the lower measurement chamber 10 through the protective gas pipe 15, Wait for the furnace sample temperature to rise to 1300 o After C, switch the argon gas to air and water vapor, the specific flow rate is: air 100ml / min, deionized water 0.007ml / min. Keep warm for 100 minutes. After the reaction is over, the reaction gas path is switched to 40ml / min high-purity argon. After cooling down to room temperature, the protective gas and reaction gas pipelines are first closed, and then the lifting device 6 is opened to take out the sample. Silicon nitride will undergo two reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com