Efficient and continuous medicine drying device

A drying device and medicine technology, applied in the direction of static material dryer, dry solid material, dry cargo handling, etc., can solve the problems of low dehydration efficiency, high risk, poor dehydration effect, etc., to improve dehydration efficiency and effective adsorption sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

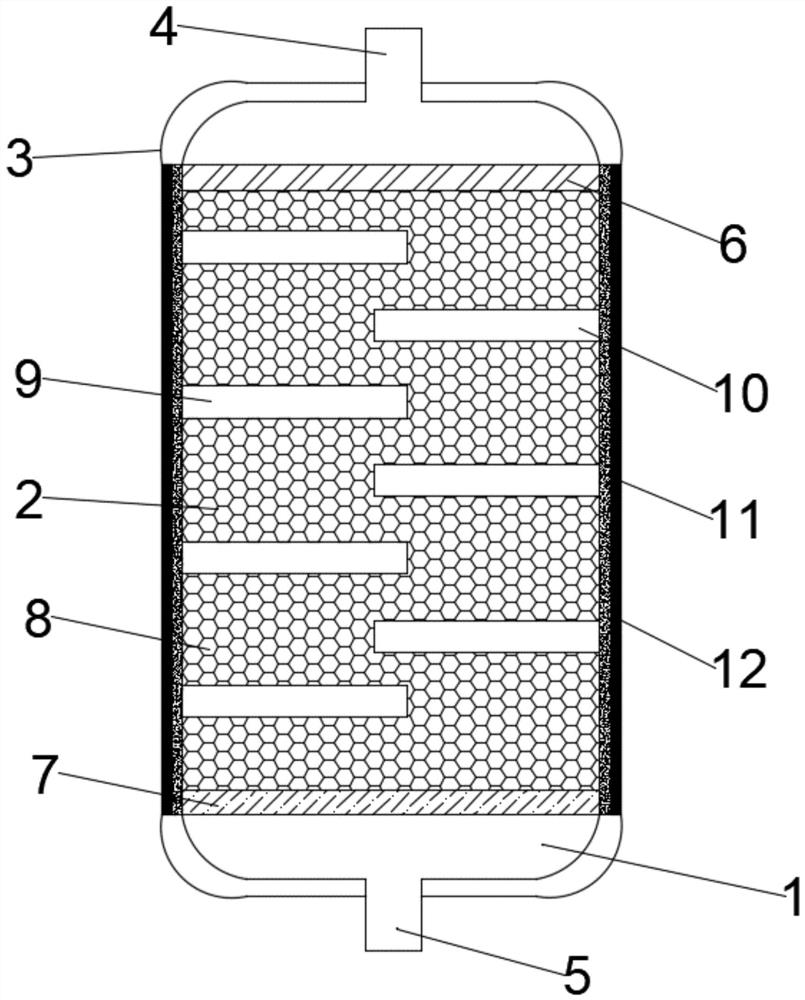

[0032] A high-efficiency continuous medicine drying device, such as figure 1 As shown, it includes a drying device body 1, the drying device body 1 includes a device cavity 2 and a device housing 3 arranged on the surface of the device cavity 2, the upper port position of the device cavity 2 is provided with a discharge port 4, and the device cavity The lower port of 2 is provided with a feed port 5, the inside of the device cavity 2 is provided with a deflector 6 on the side close to the discharge port 4, and the side of the device cavity 2 close to the feed port 5 is provided with a diffuser 7. A desiccant 8 is filled between the deflector plate 6 and the diffuser plate 7 .

[0033] Several groups of first baffles 9 and second baffles 10 are arranged between the deflector 6 and the diffuser 7, the first baffle 9 is arranged on the left side of the inner wall of the device cavity 2, and the second baffle 10 is arranged on the left side of the inner wall of the device cavity 2...

Embodiment 2

[0046] A high-efficiency continuous medicine drying device, such as figure 1 As shown, it includes a drying device body 1, the drying device body 1 includes a device cavity 2 and a device housing 3 arranged on the surface of the device cavity 2, the upper port position of the device cavity 2 is provided with a discharge port 4, and the device cavity The lower port of 2 is provided with a feed port 5, the inside of the device cavity 2 is provided with a deflector 6 on the side close to the discharge port 4, and the side of the device cavity 2 close to the feed port 5 is provided with a diffuser 7. A desiccant 8 is filled between the deflector plate 6 and the diffuser plate 7 .

[0047] Several groups of first baffles 9 and second baffles 10 are arranged between the deflector 6 and the diffuser 7, the first baffle 9 is arranged on the left side of the inner wall of the device cavity 2, and the second baffle 10 is arranged on the left side of the inner wall of the device cavity 2...

Embodiment 3

[0059] A high-efficiency continuous medicine drying device, such as figure 1 As shown, it includes a drying device body 1, the drying device body 1 includes a device cavity 2 and a device housing 3 arranged on the surface of the device cavity 2, the upper port position of the device cavity 2 is provided with a discharge port 4, and the device cavity The lower port of 2 is provided with a feed port 5, the inside of the device cavity 2 is provided with a deflector 6 on the side close to the discharge port 4, and the side of the device cavity 2 close to the feed port 5 is provided with a diffuser 7. A desiccant 8 is filled between the deflector plate 6 and the diffuser plate 7 .

[0060] Several groups of first baffles 9 and second baffles 10 are arranged between the deflector 6 and the diffuser 7, the first baffle 9 is arranged on the left side of the inner wall of the device cavity 2, and the second baffle 10 is arranged on the left side of the inner wall of the device cavity 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com