Vegetable fiber tableware and preparation method thereof

A technology of plant fiber and plant fiber shell, which is applied in the direction of manufacturing tools and wood processing appliances, etc., and can solve the problems of easy softening of the surface, easy fading, and adsorption of pigment powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

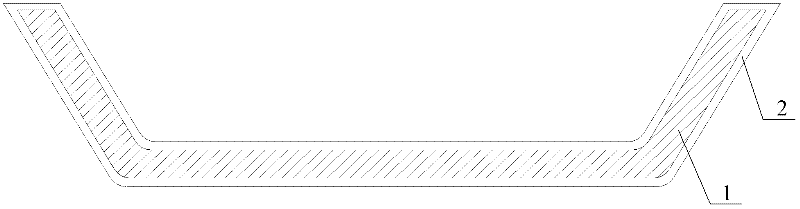

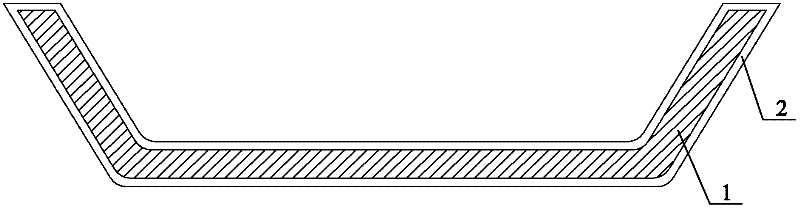

Image

Examples

preparation example Construction

[0029] The embodiment of the present invention discloses a preparation method of plant fiber tableware, comprising the following steps:

[0030] a) After mixing the raw materials evenly, they are hot-pressed to obtain the plant fiber shell; the raw materials include bamboo fiber powder, corn and Starch, urea-formaldehyde resin powder and bran;

[0031] b), grinding the surface of the plant fiber shell;

[0032] c) spraying or dip-coating water-based paint on the surface of the polished plant fiber shell and then drying to obtain plant fiber tableware.

[0033] The above method uses bamboo fiber powder, cornstarch, rice bran and urea-formaldehyde resin as raw materials, first heat-presses to form a shell, and then covers a layer of water-based paint protective film on the surface of the shell to make tableware. The surface of the plant fiber tableware prepared by the method is covered with a water-based paint film, and under the protection of the water-based paint film, exter...

Embodiment 1

[0058] 1. Take 50kg of bamboo fiber powder (50-60 mesh), 10kg of cornstarch, 30kg of urea-formaldehyde resin powder and 10kg of rice bran, mix the above raw materials evenly and pour them into a molding machine for heating and molding. The heating temperature is set to 150 and the pressure is set to is 15MPa. After the molding is completed, the mold is separated, and the plant fiber shell is taken out.

[0059] 2. Use a trimming machine to trim the corners of the plant fiber shell prepared in step 1.

[0060] 3. The surface of the plant fiber shell obtained in step 2 is polarized polished, and then the dust on the surface of the shell is cleaned.

[0061] 4. Add the resin component, curing agent component and water of the water-based paint to the mixer, the amount of water added is 15% of the water-based paint, and then carry out low-speed stirring and high-speed stirring in turn, the speed of low-speed stirring is 175rpm, and the speed of high-speed stirring is 550rpm, the ...

Embodiment 2

[0065] 1. Take 60kg of bamboo fiber powder (40-50 mesh), 5kg of cornstarch, 25kg of urea-formaldehyde resin powder, and 10kg of rice bran, mix the above-mentioned raw materials evenly, pour them into a molding machine for heating and molding, and set the heating temperature to 140°C. Set to 10MPa. After the molding is completed, the mold is separated, and the plant fiber shell is taken out.

[0066] 2. Use a trimming machine to trim the corners of the plant fiber shell prepared in step 1.

[0067] 3. The surface of the plant fiber shell obtained in step 2 is polarized polished, and then the dust on the surface of the shell is cleaned.

[0068] 4. Add the resin component, curing agent component and water of the water-based paint to the mixer, the amount of water added is 12% of the water-based paint, and then carry out low-speed stirring and high-speed stirring in turn, the speed of low-speed stirring is 150rpm, and the speed of high-speed stirring is 500rpm, the water-based ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com