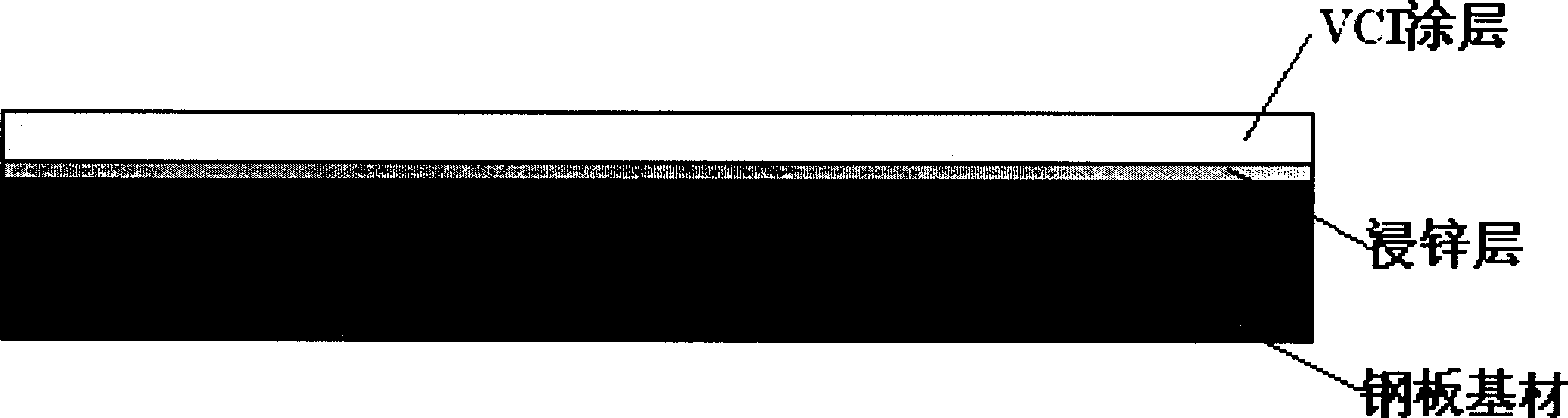

VCI-containing flake zinc and aluminum protective coating on galvanizing surface and preparation method thereof

A zinc-aluminum coating and flake technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems of corrosion and damage of steel components, limited anti-corrosion life, easy oxidation of zinc layer, etc., to achieve enhanced adhesion, long service life, and coating gloss. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1 (preparation of alcohol-soluble VCI flake zinc-aluminum composite coating)

[0071] Preparation of component A: Add 100 grams each of scale-type zinc powder and scale-type aluminum powder with a thickness ≤ 0.2 μm and a diameter ≤ 20 μm, add to 100 mL, 95% ethanol and stir for more than 0.5 hours to fully mix the two. Add 2 grams of modified polysiloxane type leveling agent, 150 grams of polyvinyl butyral and 10 grams of cyclohexylamine nitrite, and stir for more than 0.5 hours until uniform.

[0072] Preparation of component B: Dissolve 160 g of alkyl silicate in 100 mL of 95% ethanol, stir well and mix evenly, add 2 g of organic bentonite, and stir evenly.

[0073] Before coating, the two components A and B are mixed and stirred evenly to obtain a silver-gray finished alcohol-soluble zinc-aluminum composite coating.

Embodiment 2

[0074] Embodiment 2 (preparation of alcohol-soluble VCI flake zinc-aluminum composite coating)

[0075] Preparation of component A: 180 grams each of flake-type zinc powder and flake-type aluminum powder with a thickness ≤ 0.4 μm and a diameter ≤ 40 μm are added to 200 mL of 95% n-butanol and stirred for more than 0.5 hours to fully mix the two Evenly, add 5 grams of leveling agent M, 200 grams of polyvinyl butyral and 20 grams of hexamethylenetetramine, and stir for more than 0.5 hours until uniform.

[0076] Preparation of component B: Dissolve 200 grams of alkyl silicate in 100 mL of 95% n-butanol, stir and mix well, add 10 grams of fumed silica, and stir evenly.

[0077] Before coating, the two components A and B are mixed and stirred evenly to obtain a silver-gray finished alcohol-soluble zinc-aluminum composite coating.

Embodiment 3

[0078] Embodiment 3 (preparation of alcohol-soluble VCI flake zinc-aluminum composite coating)

[0079] Preparation of component A: 30 grams each of flake-type zinc powder and scale-type aluminum powder with a thickness of ≤0.1 μm and a diameter of ≤15 μm are added to 100 mL of 95% diethylene glycol and stirred for more than 0.5 hours to make the two fully Mix evenly, add 1 gram of polyacrylic acid, 200 grams of polyvinyl butyral and 5 grams of dicyclohexylamine, and stir for more than 0.5 hours until uniform.

[0080] Preparation of component B: Dissolve 100 grams of alkyl silicate in 100 mL of 95% diethylene glycol, stir and mix well, add 5 grams of organic bentonite, and stir evenly.

[0081] Before coating, the two components A and B are mixed and stirred evenly to obtain a silver-gray finished alcohol-soluble zinc-aluminum composite coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Film diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com