Full-dull colorful insulation polyester film and production technology thereof

A polyester film, full extinction technology, used in the polyester film industry, can solve the problems of production environment pollution, low insulation performance, poor color fastness, etc., to solve uneven smooth, good insulation performance, high electrical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

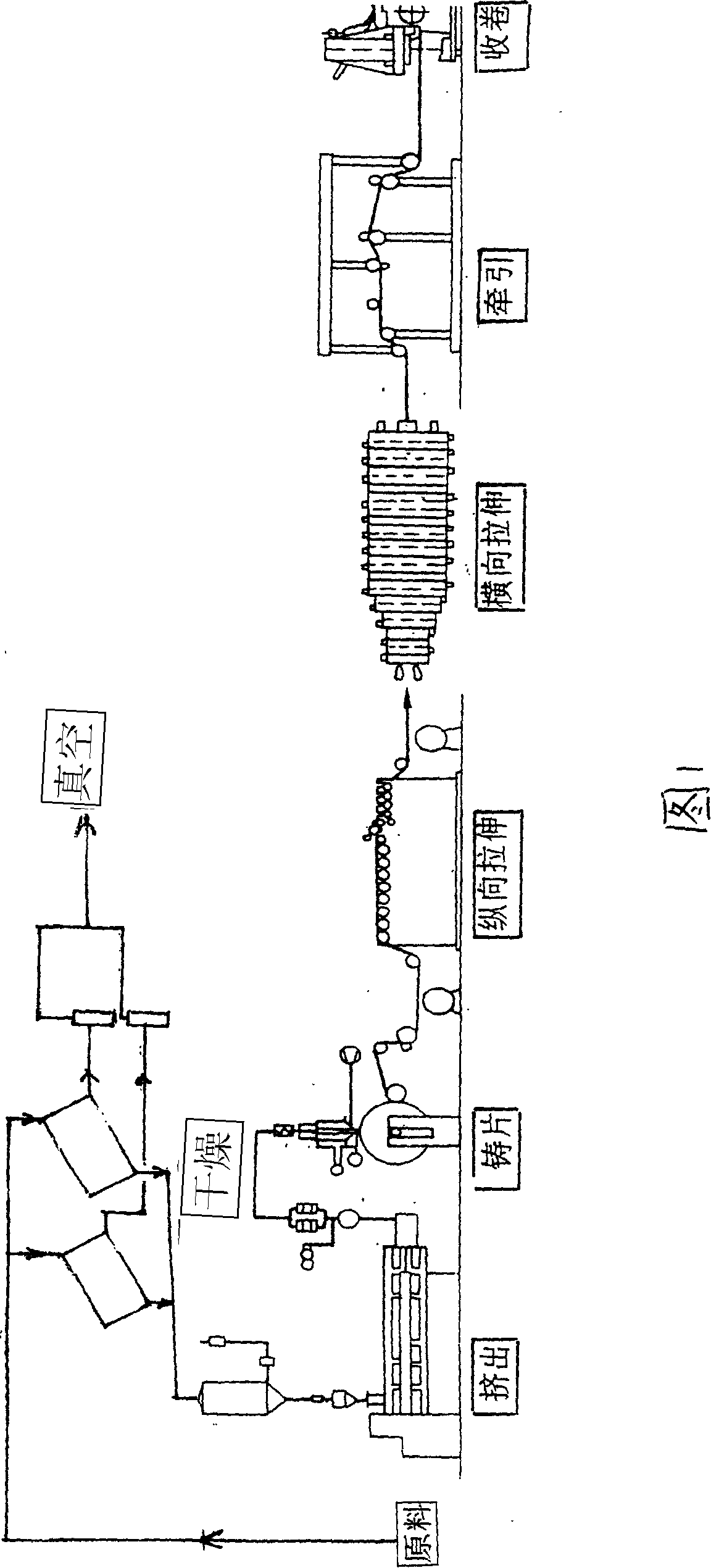

Method used

Image

Examples

Embodiment 1

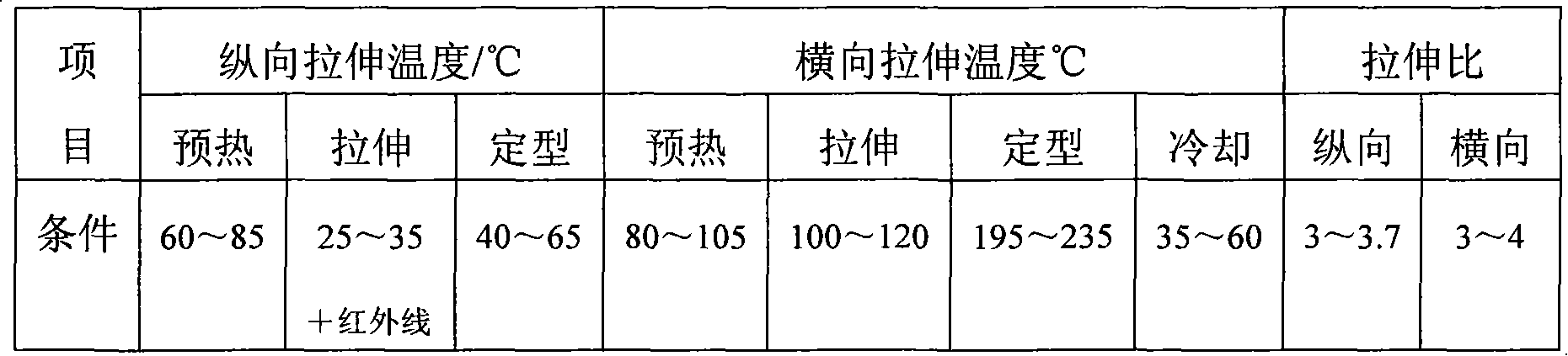

[0013] Embodiment 1: full extinction yellow electrical insulating polyester film and its production process.

[0014] Matte film grade polyester chips, yellow color masterbatch, SiO 2 The three materials of the polyester masterbatch are proportioned according to the ratio of 25:4:4. Among them, TBY115B organic yellow masterbatch is selected as the yellow masterbatch. This kind of masterbatch does not decompose at 220 to 285°C, and has good mutual solubility, no non-melting particles, good color fastness, and high film-forming property. The matting film grade polyester chip is made by adding matting agent to the blank polyester chip, and the content of matting agent is: 2.5-5%. Contains SiO 2 The particle size of the polyester masterbatch is controlled at about 0.5 μm, and an antistatic agent must be added. Under the premise of meeting the requirements of the dielectric constant index, the content of matting agent is 50-100ppm, depending on the user's requirements.

[0015]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com