One-step breathable film and preparation method thereof

A gas-permeable film and one-step technology, which is applied in the field of one-step gas-permeable film and its preparation, can solve the problems of low water vapor transmission rate, poor comprehensive performance of the gas-permeable film, and uneven thickness of the film, so as to save granulation configuration Artificial, high water vapor transmission efficiency, and the effect of reducing the degradation of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

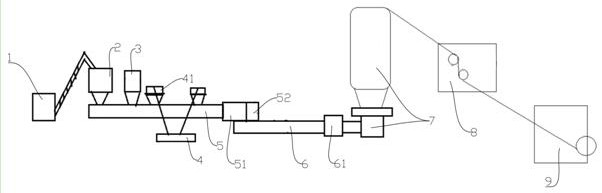

[0039]A method for preparing a one-step gas-permeable film. The one-step gas-permeable film is produced by a one-step film blowing device, which includes the following steps:

[0040]A. Inorganic powder activation treatment: Put the inorganic powder with a particle size of 1~3um into a high-speed mixer, and perform dehydration treatment at a speed of 400~1000r / min and a temperature of 100~150℃ for 5~15min; then add the compound Surface active coupling agent, mixed and coated at a speed of 400-1000r / min and a temperature of 100-150°C for 5-15min to make an active inorganic powder;

[0041]In step A, the mass ratio of the inorganic powder to the composite surface active coupling agent is 10:0.7-0.9;

[0042]B. Use the mixing device 1 to mix the air-permeable film plastic particles uniformly to form mixed air-permeable film plastic particles, and then convey them to the feeding port of the twin-screw extruder 5, and use the first feeding device 2 to discharge the active inorganic powder The bod...

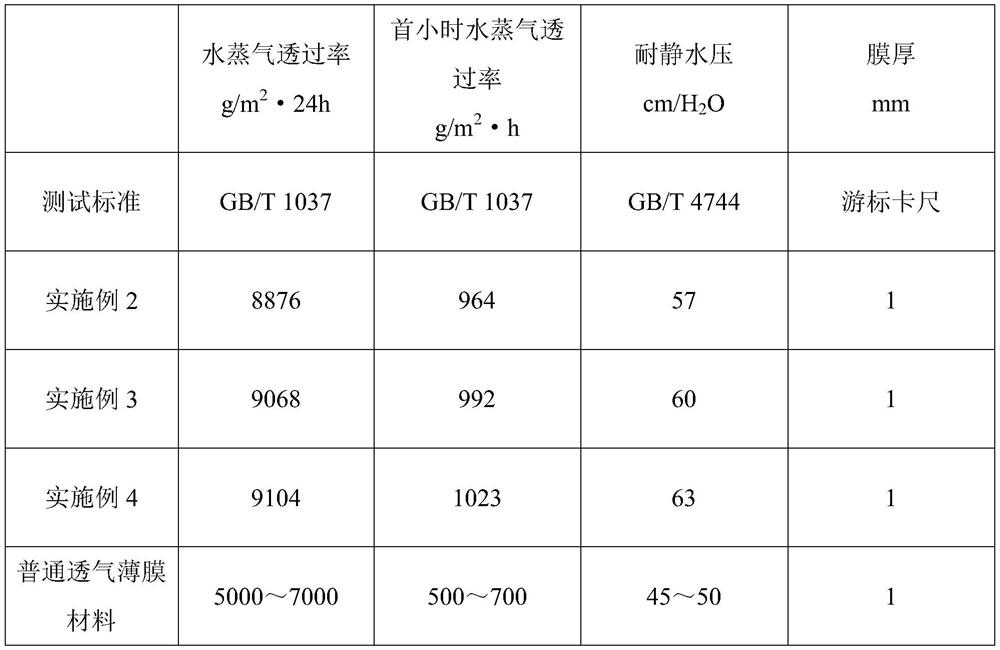

Embodiment 2

[0055]A method for preparing a one-step gas-permeable film. The one-step gas-permeable film is produced by a one-step film blowing device, which includes the following steps:

[0056]A. Inorganic powder activation treatment: Put the inorganic powder with a particle size of 1 into a high-speed mixer, and carry out dehydration treatment at a speed of 400r / min and a temperature of 100°C for 15min; then add a composite surface active coupling agent at a temperature of 400r / min. / min speed, 100 ℃ temperature for 15min mixed coating treatment, made into active inorganic powder;

[0057]In step A, the mass ratio of the inorganic powder to the composite surface active coupling agent is 10:0.7;

[0058]B. Use the mixing device 1 to mix the air-permeable film plastic particles uniformly to form mixed air-permeable film plastic particles, and then convey them to the feeding port of the twin-screw extruder 5, and use the first feeding device 2 to discharge the active inorganic powder The body is fed fro...

Embodiment 3

[0071]A method for preparing a one-step gas-permeable film. The one-step gas-permeable film is produced by a one-step film blowing device, which includes the following steps:

[0072]A. Inorganic powder activation treatment: Put the inorganic powder with a particle size of 3um into a high-speed mixer, and perform dehydration treatment at a speed of 1000r / min and a temperature of 150°C for 5min; then add a composite surface active coupling agent at a temperature of 1000r / min. / min speed, 150℃ temperature for 5min mixed coating treatment, made into active inorganic powder;

[0073]In step A, the mass ratio of the inorganic powder to the composite surface active coupling agent is 10:0.9;

[0074]B. Use the mixing device 1 to mix the air-permeable film plastic particles uniformly to form mixed air-permeable film plastic particles, and then convey them to the feeding port of the twin-screw extruder 5, and use the first feeding device 2 to discharge the active inorganic powder The body is fed from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com