Method for preparing black monodisperse polymer microspheres

A polymer, black single technology, applied in the field of materials, can solve the problems of many post-processing processes and complicated processes, and achieve the effects of uniform particle size distribution, uniform particle size, and strong crush resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] (1) Preparation of seed microspheres

[0048] The polymer seed microspheres were prepared by soap-free emulsion polymerization or dispersion polymerization. Both can produce bulbs with excellent properties. See figure 2 , 3.

[0049] The soap-free emulsion polymerization method is to react the monomer, electrolyte and initiator in the nitrogen atmosphere at constant temperature. The monomer is refined styrene, the initiator is water-soluble potassium persulfate (KPS), and the dosage is 1% of the mass of the monomer.

[0050] The dispersion polymerization method is to react the formulated amount of dispersant, initiator and monomer at constant temperature under nitrogen atmosphere. Polyvinylpyrrolidone (PVP) was selected as the dispersant, and the dosage was 13% of the mass of the monomer; azobisisobutyronitrile (AIBN) was selected as the initiator, and the dosage was 7% of the mass of the monomer.

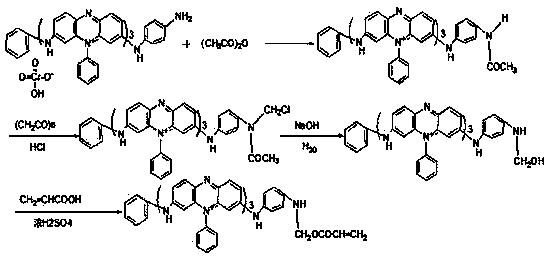

[0051] (2) Preparation of black microspheres

[0052] Black m...

Embodiment 1

[0064] Take 0.12 g of sodium chloride, add the refined styrene monomer into 100 mL of deionized water and ultrasonically disperse to a homogeneous phase, and then slowly add deoxygenated potassium persulfate aqueous solution (0.002 g / mL) dropwise, After the addition was completed, the nitrogen atmosphere was maintained for 30 min, and then the temperature was raised to 70 °C for constant temperature polymerization in a nitrogen atmosphere for 18 h. After the reaction, the obtained particles were repeatedly centrifuged and washed with deionized water for 7 times, and finally the obtained seed polymer microspheres were redispersed in deionized water, and nitrogen gas was blown in for 30 minutes to remove the residual styrene monomers to obtain Seed bulb lotion.

Embodiment 2

[0066] Weigh 0.6 g of swelling agent and add it to 30 g SDBS aqueous solution for ultrasonic dispersion. After the solution becomes homogeneous, crush it with a cell homogenizer for 5 min, then add 1 g of the seed emulsion into this homogeneous emulsion, and keep the reactor temperature at 30 It was stirred and swelled at ℃ for 12 h to obtain emulsion A.

[0067] The MAA / EGDMA (1:1) monomer emulsion 3g that is dissolved in benzoyl peroxide (mass fraction is 1%), black reactive black dye monomer containing double bond and 30 g SDBS aqueous solution are ultrasonically mixed to obtain the emulsion b. It was added to emulsion A and swelled at 30 °C for 24 h to obtain emulsion C. Add 10 g, 5% polyvinyl alcohol aqueous solution to the above-mentioned emulsion C, pass nitrogen gas for 0.5 h, then raise the temperature to 70 °C, stir and swell for 8 h.

[0068] The obtained polymer microspheres were respectively centrifuged with DMF and ethanol and washed three times with ultrasonic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com