Device and method for replacing non-excavation underground pressure-bearing pipeline

A non-excavation and pipeline technology, applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as low efficiency, restricted application, and large environmental pollution of circulating mud

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

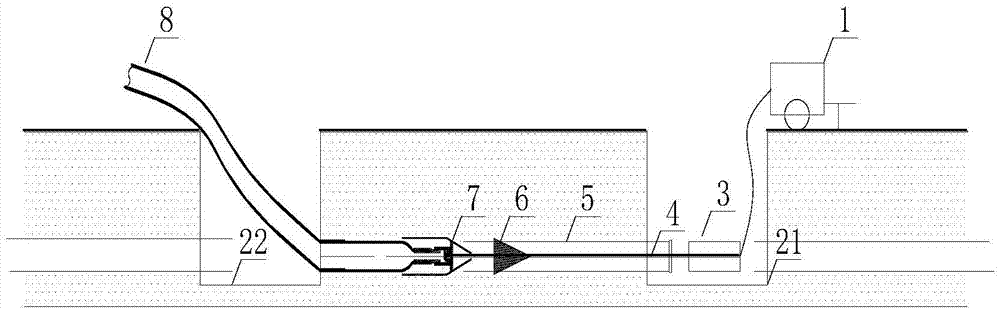

[0027] In order to better understand the purpose, structure and function of the present invention, a replacement device and method for trenchless underground pressure-bearing pipelines of the present invention will be described in further detail below in conjunction with the accompanying drawings.

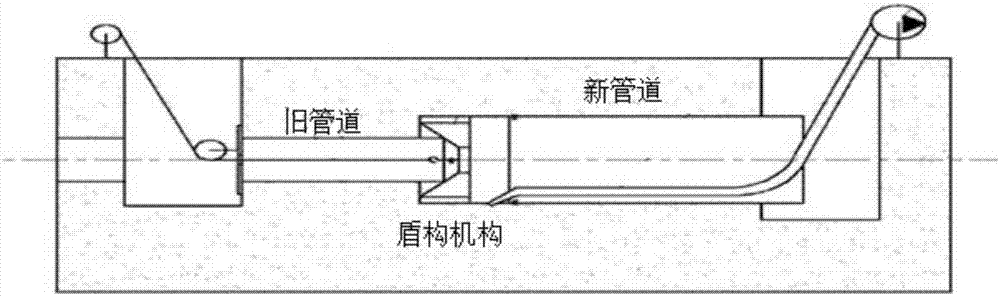

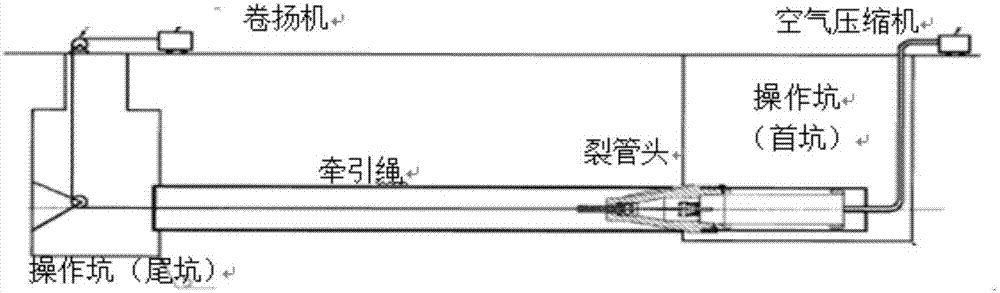

[0028] Such as Figure 3 to Figure 8 As shown, it is a replacement device for a non-excavation underground pressure-bearing pipeline of the present invention, including a drill pipe retractable device 3, an anti-slip drill pipe 4, an old pipe cutter 6, a pipe expansion head 7 and a flexible composite pipe 8. The drill pipe retractable device 3 is located at one end of the old pipe 5; one end of the anti-slip drill pipe 4 is connected to the drill pipe retractable device 3, and the drill pipe retractable device 3 pushes the anti-slip drill pipe 4 through the inside of the old pipe 5 to reach At the other end of the old pipeline 5; the old pipeline cutter 6 is used to cut the old pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com