Preparation method and application of heat-resistant ferritin

A technology for ferritin and protein, which is applied in the field of biomimetic mineralization and synthesis of heat-resistant magnetic ferritin materials, can solve the problems of insignificant improvement in thermal stability of ferritin, high cost of chemical modifiers, complicated modification process, etc., and achieves high thermal stability. good dispersibility and large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] 1. Construction of expression vector for PcFn-encoding gene

[0059] Find the gene sequence of Pyrococcusyayanosii CH1 encoding ferritin PcFn in GenBank, the accession number is 10837266, and NdeI and EcoRI restriction sites are added at the beginning and end, as shown in SEQ ID NO:1. The sequence of SEQ ID NO: 1 was modified with codon bias, as shown in SEQ ID NO: 3, in order to allow the gene to be expressed more efficiently in the E. coli expression system. The cDNA strand of the sequence shown in SEQ ID NO:3 was synthesized by Beijing Liuhe Huada Gene Company, and the synthetic product was pUC57-PcFn plasmid, which was stored in the puncture bacteria. Amplify and purely culture the puncture bacteria and use the kit to extract the pUC57-PcFn plasmid, pUC57-PcFn plasmid and pET22b plasmid are simultaneously digested with restriction endonucleases NdeI and EcoRI, and after agarose electrophoresis detection, use DNA gel to recover Kit for recovery and purification. Th...

Embodiment 2

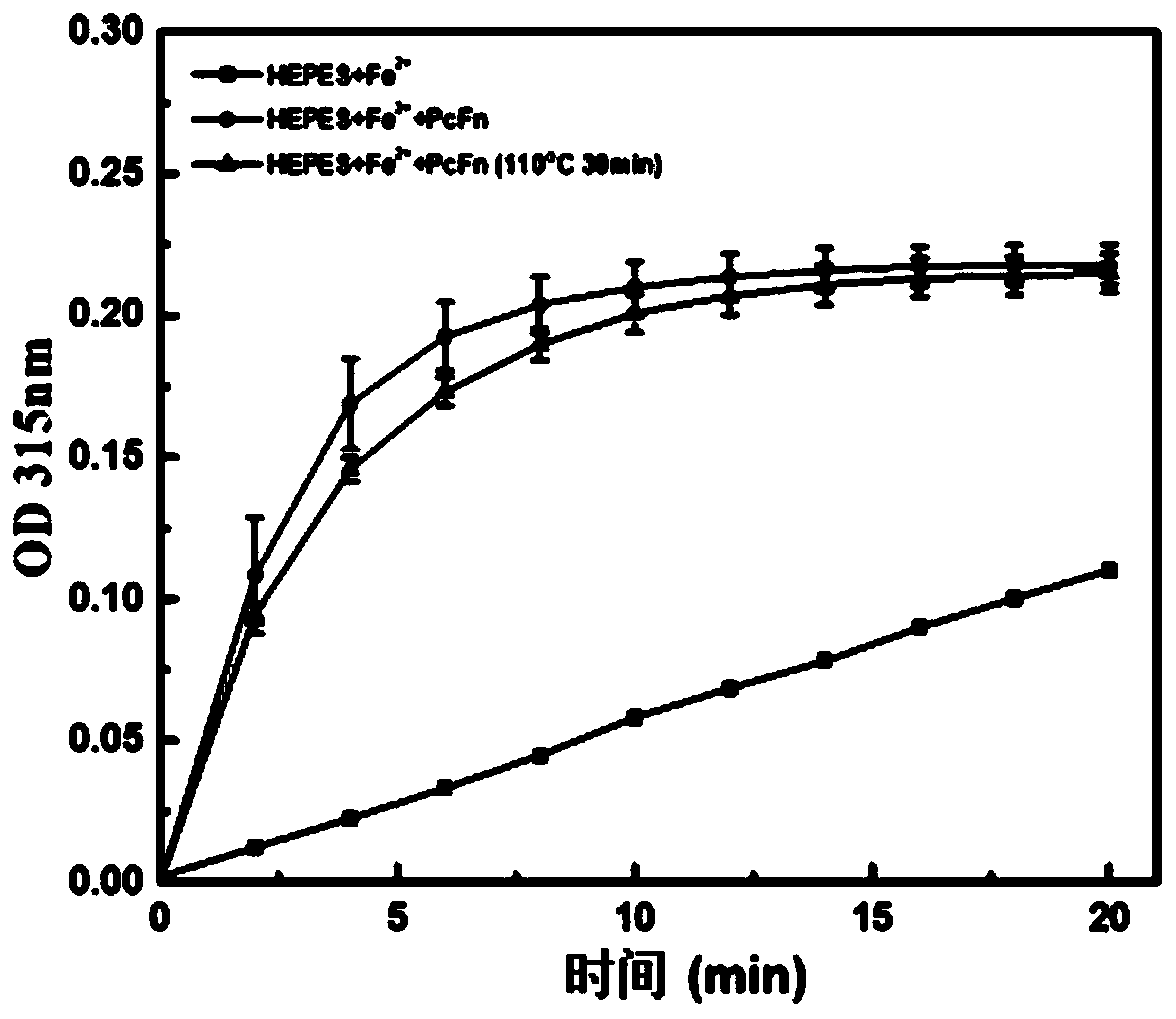

[0098] 1. Magnetic ferritin M-PcFn 5000 biomimetic synthesis of

[0099] The purified PcFn ferritin cage structure in Example 1 was desalted with 0.1 M sodium chloride solution, diluted to 0.5 mg / mL after concentration measurement, and 50 mL was taken and put into a reaction vessel for later use. The deionized water was degassed and deoxygenated with a vacuum pump for 30 minutes, and then filled with high-purity argon. Prepare 0.1M NaOH, 50mM ferrous ammonium sulfate, and 16.67mM hydrogen peroxide solution in the anaerobic box with deaerated water, connect the reaction device and start heating and stirring, set the reaction temperature to 65°C, and use sodium hydroxide to dissolve the protein solution Adjust the pH to 8.5, start the reaction program when the temperature reaches 65°C, control the reaction rate so that each ferritin shell enters 80 ferrous ions per minute, and ensure that the number of ferrous ions added to the reaction system and the molar ratio of hydrogen pe...

Embodiment 3

[0105] According to the steps of constructing the expression vector of the PcFn-encoding gene in Example 1 and transforming the pET22b-PcFn plasmid into the Escherichia coli BL21 (DE3) engineering bacteria, the engineering bacteria containing the PcFn-encoding gene were obtained, and then the screened positive clones were inoculated into the liquid LB culture Incubate at 37°C in medium until the OD value is 0.6, add IPTG inducer to activate the T7 promoter, and culture at 30°C for 8h. Collect the cells by centrifugation, resuspend the cells in PBS buffer, and add lysozyme to treat at 37°C for 2.5 hours. The resuspension was placed on ice for 8 minutes by ultrasonication, and the cell lysate was centrifuged at 20,000g for 30 minutes at 4°C to collect the protein supernatant.

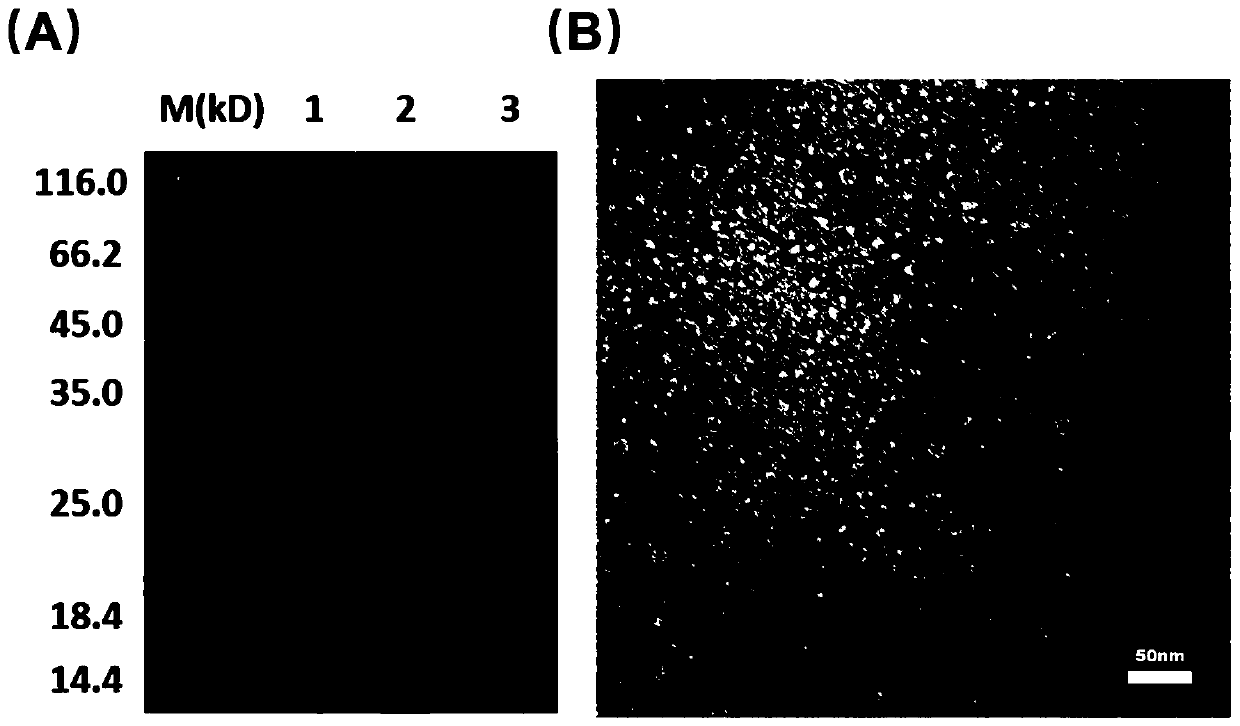

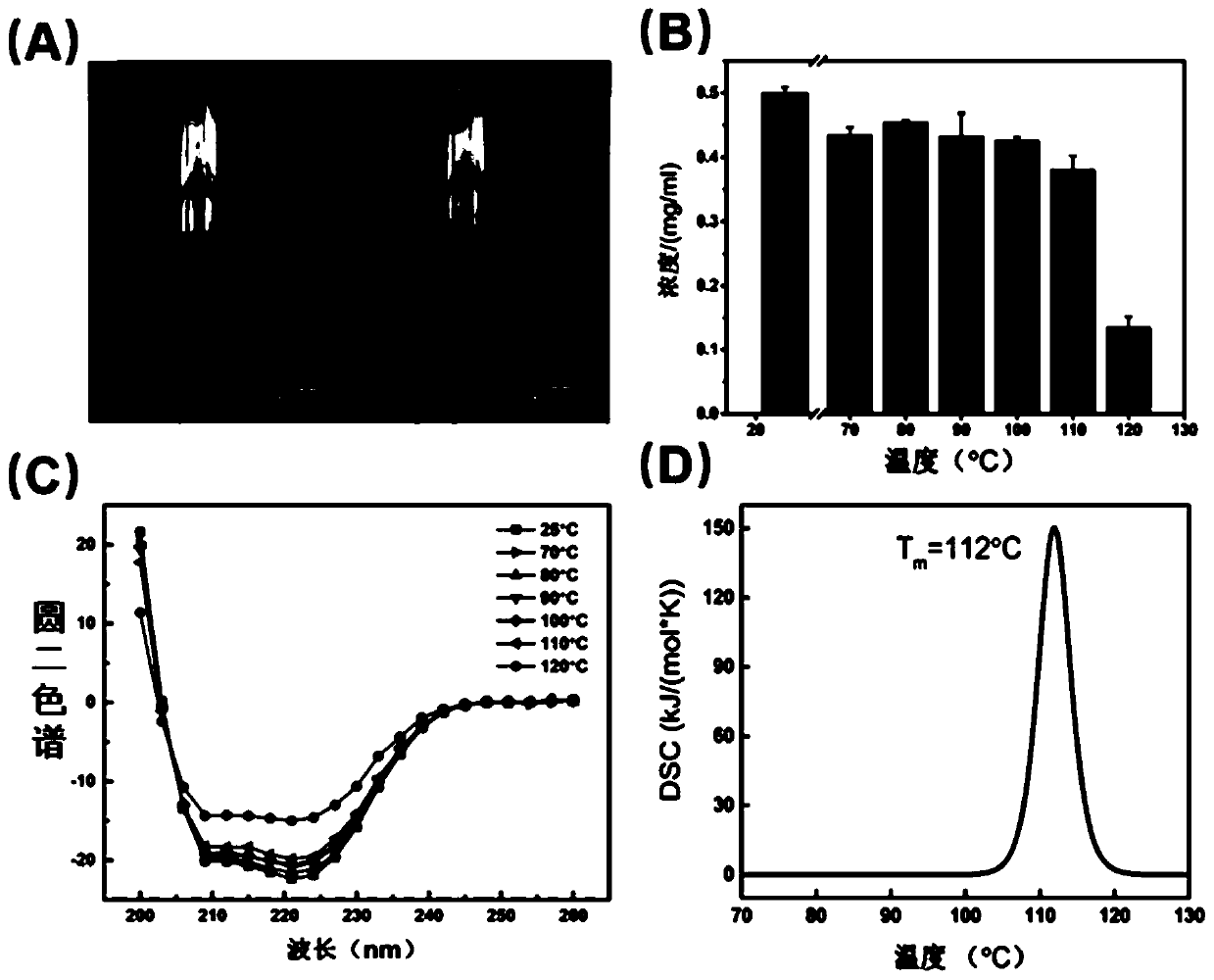

[0106] The supernatant was heated in water at 80° C. for 30 minutes, and then centrifuged at 20,000 g for 30 minutes at 4° C. to obtain the purified PcFn protein. The results showed that the PcFn protein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com