Novel reflecting film

A reflective film, a new type of technology, applied in the field of reflective film, can solve the problems of single function of reflective film and poor reflection effect, and achieve the effect of enhancing reflectivity, reducing gaps, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

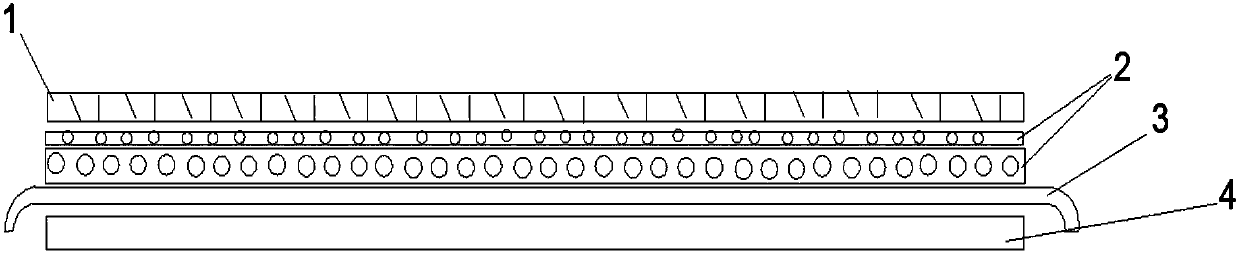

[0032] A new type of reflective film, which sequentially includes a scratch-resistant layer (1), a foam layer (2), a peripheral layer (3) and a bottom layer (4) from top to bottom, and the scratch-resistant layer (1) is arranged to be mutually The matching first trapezoidal reinforcing particles and the second trapezoidal reinforcing particles are snapped together, the foam layer (2) includes a micro-foam layer and a high foam layer, and the foam layer (2) and the peripheral layer (3) pass through The hot pressing method and the peripheral layer constitute an integral structure, and the peripheral layer (3) is shaped with a peripheral arc edge through high-temperature shaping.

Embodiment 2

[0034] On the basis of Example 1, the surface of the anti-scratch layer (1) is sprayed with inorganic ions.

Embodiment 3

[0036] On the basis of Example 1, the micro-bubble layer and the high-bubble layer are pasted with a phenolic resin adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com