Reinforced wear-resistant PE gas pipe and preparation method thereof

A technology of gas pipes and raw materials, which is applied in chemical instruments and methods, tubular objects, and other household appliances, and can solve problems such as unsatisfactory wear resistance and compression resistance, lack of mixing, waste of granulation equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

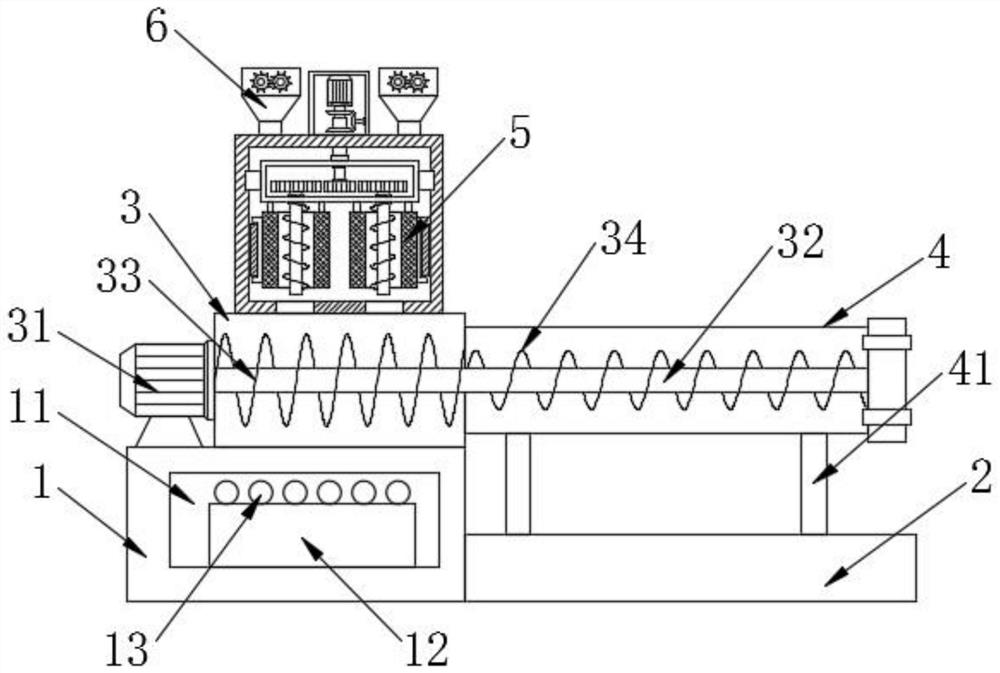

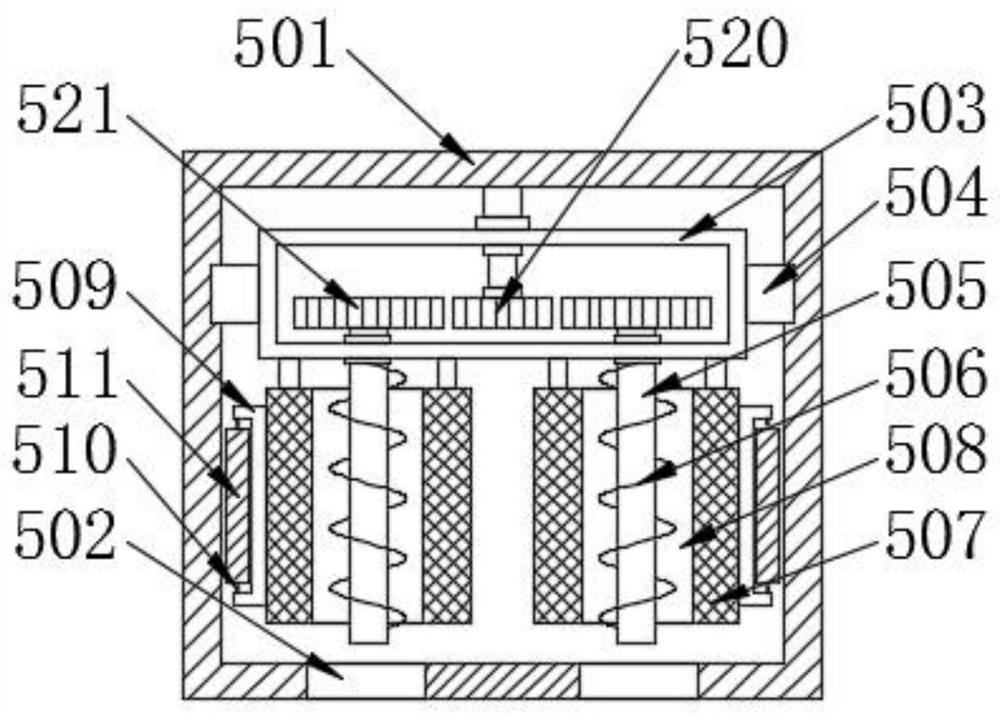

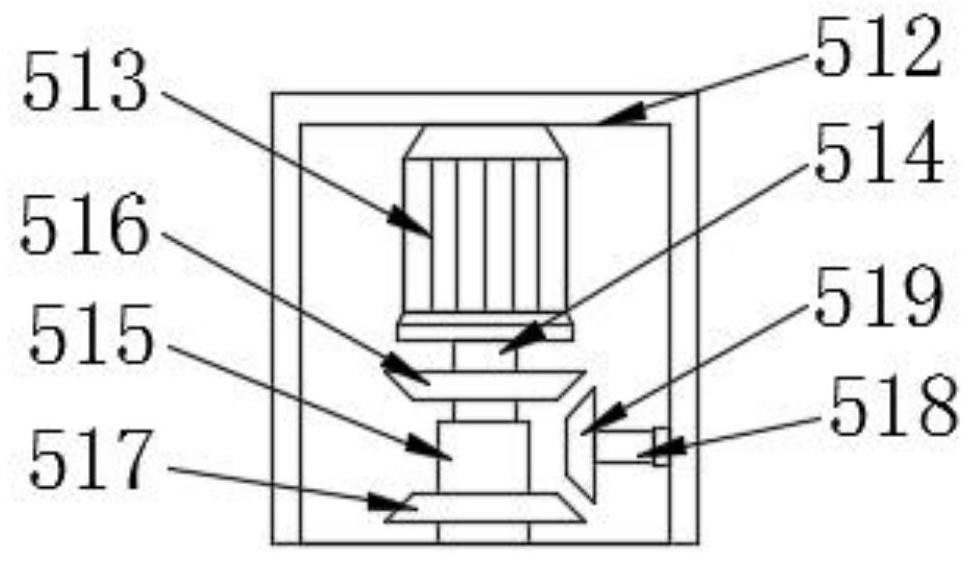

Method used

Image

Examples

Embodiment 1

[0065] A reinforced wear-resistant PE gas pipe, including an inner layer, a core layer, and an outer layer. The inner layer is prepared from the following raw materials in parts by weight: 90 parts of polyethylene resin, 4 parts of graphene functional masterbatch, and the core layer is made of the following weight parts: Parts of raw materials are prepared: 100 parts of polyethylene graft resin, and the outer layer is prepared by the following parts by weight of raw materials: 90 parts of block copolymerized polypropylene, 3 parts of graphene functional masterbatch;

[0066] The enhanced wear-resistant PE gas pipe is prepared by the following steps:

[0067] Add the raw materials of the inner layer, core layer and outer layer into a three-layer co-extrusion mold, carry out co-extrusion outer layer treatment, and compound extrusion molding at a temperature of 190°C to obtain a reinforced wear-resistant P gas pipe;

[0068] The enhanced wear-resistant graphene functional masterb...

Embodiment 2

[0080] A reinforced wear-resistant PE gas pipe, including an inner layer, a core layer, and an outer layer. The inner layer is prepared from the following raw materials in parts by weight: 92 parts of polyethylene resin, 6 parts of graphene functional masterbatch, and the core layer is made of the following weight parts: Parts of raw materials are prepared: 110 parts of polyethylene graft resin, and the outer layer is prepared by the following parts by weight of raw materials: 925 parts of block copolymerized polypropylene, 5 parts of graphene functional masterbatch;

[0081] The enhanced wear-resistant PE gas pipe is prepared by the following steps:

[0082] Add the raw materials of the inner layer, core layer and outer layer into a three-layer co-extrusion mold, perform co-extrusion outer layer treatment, and compound extrusion molding at a temperature of 205°C to obtain a reinforced wear-resistant P gas pipe;

[0083] The enhanced wear-resistant graphene functional masterba...

Embodiment 3

[0095] A reinforced wear-resistant PE gas pipe, including an inner layer, a core layer, and an outer layer. The inner layer is prepared from the following raw materials in parts by weight: 94 parts of polyethylene resin, 7 parts of graphene functional masterbatch, and the core layer is made of the following weight parts: Parts of raw materials are prepared: 120 parts of polyethylene graft resin, and the outer layer is prepared by the following parts by weight of raw materials: 95 parts of block copolymerized polypropylene, 6 parts of graphene functional masterbatch;

[0096] The enhanced wear-resistant PE gas pipe is prepared by the following steps:

[0097] Put the raw materials of the inner layer, core layer and outer layer into a three-layer co-extrusion mold, carry out co-extrusion outer layer treatment, and co-extrude at a temperature of 190-220°C to obtain a reinforced wear-resistant P gas pipe;

[0098] The enhanced wear-resistant graphene functional masterbatch is prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com