Method for simply and quickly preparing carbon-doped zinc oxide nanosheet

A zinc oxide nanometer and rapid technology, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of harsh preparation conditions, unfavorable industrialization, and many processes, and achieve controllable reaction conditions, convenient operation, and repeatability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A simple and fast method for preparing carbon-doped zinc oxide nanosheets, comprising the following preparation steps:

[0025] (1) Weigh a certain mass of basic zinc carbonate and small molecular organic matter, and grind them so that they are fully mixed and even.

[0026] (2) Place the basic zinc carbonate and small molecular organic matter mixed uniformly in step (1) in an air-free vacuum environment for calcination, and then naturally cool to room temperature.

[0027] (3) Grinding the powder calcined in step (2), the powder obtained by grinding is carbon-doped zinc oxide nanosheets.

Embodiment 2

[0029] A simple and fast method for preparing carbon-doped zinc oxide nanosheets, comprising the following preparation steps:

[0030] (1) Weigh a certain mass of basic zinc carbonate and small molecular organic matter, the mass ratio of basic zinc carbonate and small molecular organic matter is 4:1-8:1, and the basic zinc carbonate and small molecular organic matter are placed in the agate laboratory. Grind in a bowl for 10-60 min to fully mix the two; the small molecular organic matter is sucrose, oxalic acid, glucose, fructose or citric acid.

[0031] (2) Spread the basic zinc carbonate and small molecular organic matter evenly mixed in step (1) on the quartz boat, and put the quartz boat into the quartz tube of the tube furnace.

[0032] (3) Vacuumize the tube furnace so that the quartz tube in step (2) is placed in an air-free vacuum environment and calcined at 300-800°C with a heating rate of 1°C / min-10°C / min , keep warm for 1h-5h and then cool down to room temperature ...

Embodiment 3

[0035] A simple and fast method for preparing carbon-doped zinc oxide nanosheets, comprising the following preparation steps:

[0036] (1) Weigh 2g of basic zinc carbonate and 0.5g of sucrose respectively, place them in an agate mortar and grind for 10-60 minutes, so that the two are fully mixed and even.

[0037] (2) Spread the basic zinc carbonate and sucrose evenly mixed in step (1) on the quartz boat, and put the quartz boat into the quartz tube of the tube furnace.

[0038] (3) Vacuumize the tube furnace so that the quartz tube in step (2) is placed in an air-free vacuum environment and calcined at 300-800°C with a heating rate of 10°C / min. After 2 hours of heat preservation, it will naturally Cool to room temperature.

[0039] (4) Grind the powder calcined in step (3) with an agate mortar, and the powder obtained by grinding is carbon-doped zinc oxide nanosheets.

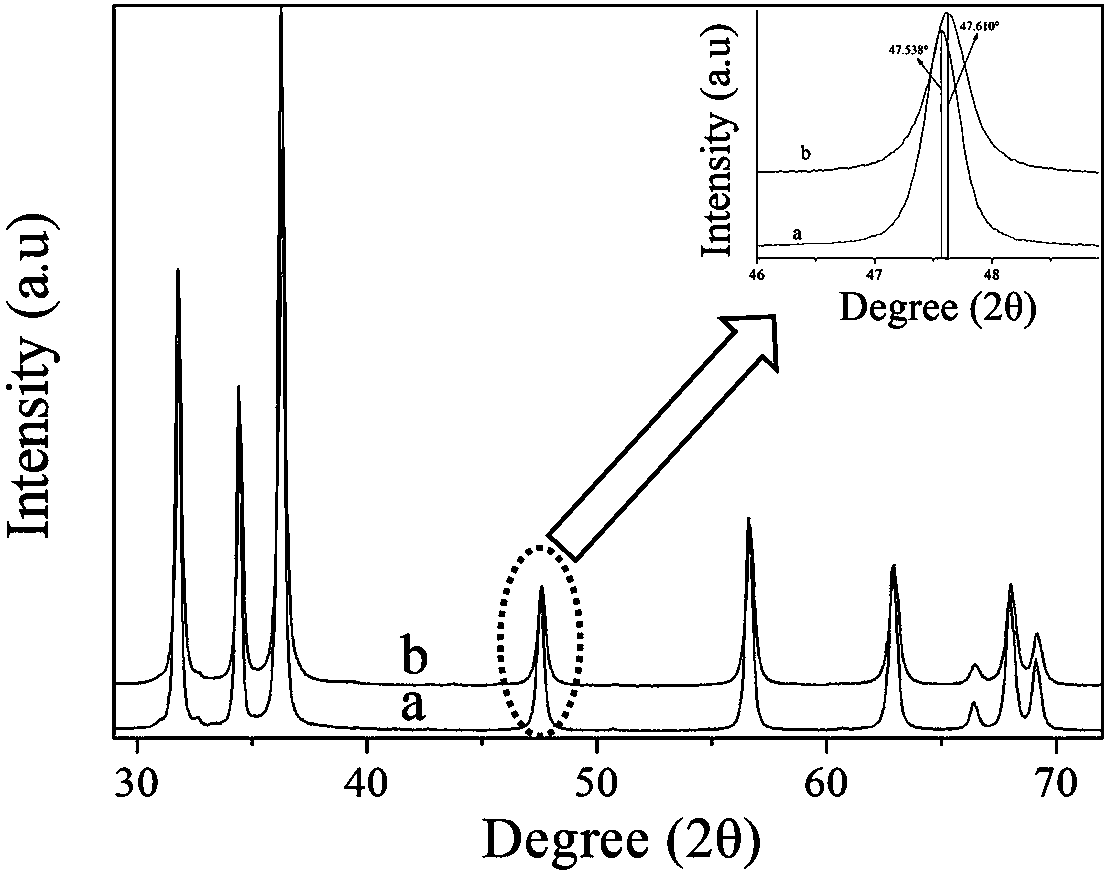

[0040] Detect the carbon-doped zinc oxide nanosheets prepared in Example 3

[0041] 1. Scanning electron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com