Fluorine-containing polysiloxane rubber state composite gas separation membrane, preparation method and application thereof

A polysiloxane and composite gas technology, applied in separation methods, semi-permeable membrane separation, dispersed particle separation, etc., can solve problems such as the destruction of the support layer, the inability to directly apply gas separation membranes, etc., to achieve good swelling resistance, preparation mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Select porous polyetherimide and polycarbonate with a porosity of 60-80% and a pore diameter of 0.3-0.6 μm as the support membrane; use fluorine-containing polysiloxane (molecular weight Mw=300000-600000) and solvent ethyl acetate , prepare a coating solution with a concentration of 15%, add a cross-linking agent hydrogen-containing silicone oil and a catalyst platinum complex, the concentrations are 2wt.% and 0.15wt.%, stir well and let it stand until there are no bubbles by visual inspection That's it.

[0025] The film liquid is respectively coated on the porous polyetherimide and the polycarbonate support film by a one-step roller coating method; the crosslinking temperature of the oven is controlled at 70-80°C, and it is cured by heating until dry without residual solvent.

[0026] Use it for oxygen nitrogen separation and carbon dioxide nitrogen separation:

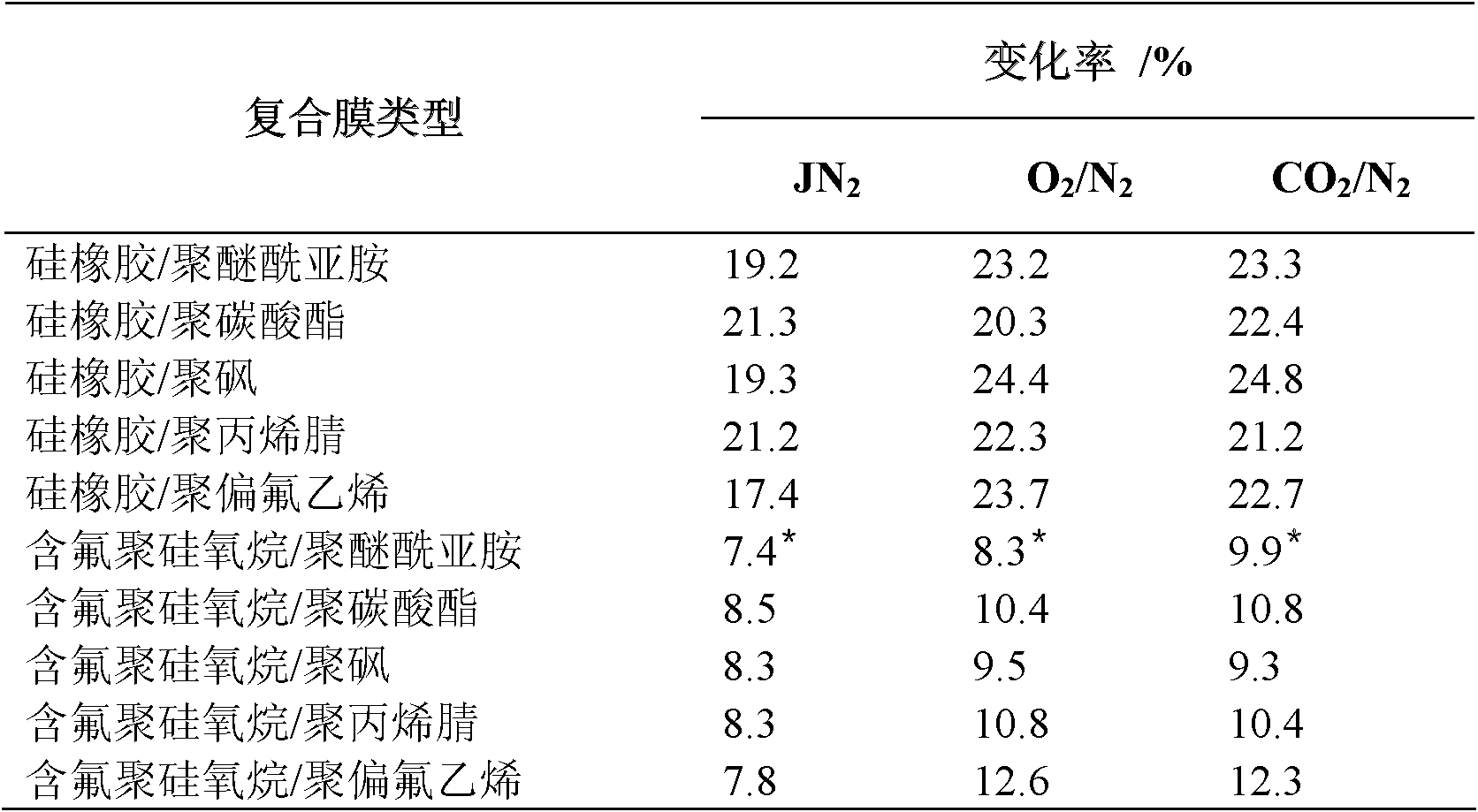

[0027] The gas permeation flux and selectivity of fluoropolysiloxane / polyetherimide composite membranes a...

Embodiment 2

[0029] Select porous polyetherimide and polysulfone with a porosity of 60-80% and a pore diameter of 0.3-0.6 μm as the supporting membrane; use fluorine-containing polysiloxane (molecular weight Mw=700000-900000) and solvent ethyl acetate, Prepare the coating solution at a concentration of 12wt.%, add a cross-linking agent hydrogen-containing silicone oil and a catalyst platinum complex, the concentrations of which are 3wt.% and 0.2wt.%, stir well and let it stand until there are no bubbles by visual inspection That's it.

[0030] The film liquid is respectively coated on the porous polyetherimide and polysulfone support membranes by a one-step roller coating method, and the crosslinking temperature of the oven is controlled at 75-85°C, and it is cured by heating until it is dry and there is no residual solvent.

[0031] Use it for oxygen nitrogen separation and carbon dioxide nitrogen separation:

[0032] The gas permeation flux and selectivity of fluoropolysiloxane / polyethe...

Embodiment 3

[0034] Select porous polyetherimide with a porosity of 60-80% and a pore diameter of 0.3-0.6 μm and porous polyacrylonitrile and polyvinylidene fluoride with a porosity of 60-80% and a pore diameter of 0.5-0.7 μm as the support membrane ;Use fluorine-containing polysiloxane (molecular weight Mw=100000~1100000) and solvent ethyl acetate, configuration concentration is the coating liquid of 5wt.%, adds crosslinking agent hydrogen-containing silicone oil and catalyst platinum complex thereinto, its Concentrations are 2wt.% and 0.1wt.%, respectively, after stirring evenly, let it stand until there are no bubbles by visual inspection.

[0035] The membrane solution is coated on the porous polyetherimide support membrane by one-step roller coating method, and the membrane solution is coated on porous polyacrylonitrile and polyvinylidene fluoride by multi-step roller coating method (2-4 times of roller coating). On ethylene, control the crosslinking temperature of the oven at 80-90°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com