A light-weight, high-strength, water-resistant decorative gypsum board and its processing method

A processing method and gypsum board technology, which are applied in the field of gypsum board processing, can solve the problems of poor noise reduction effect and reduced impact resistance of foamed gypsum, so as to ensure the aesthetic effect of application, improve the moisture absorption capacity, and increase the tensile resistance. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

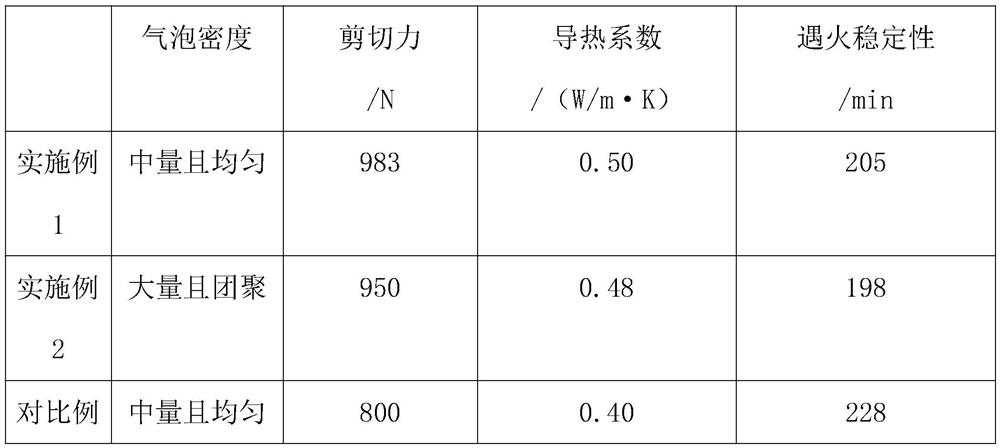

Embodiment 1

[0034] The invention provides a technical solution: a light-weight, high-strength, water-resistant decorative gypsum board, which is prepared from the following components in parts by weight: 70-80 parts of gypsum powder, 5-10 parts of diatomite, 1 ~3 parts of corn starch, 0.5~3 parts of foam stabilizer, 5~10 parts of granite particles, 3~5 parts of graphene oxide sheets, 3~5 parts of silicon acrylic emulsion, 0.3~0.9 parts of waste paper pulp fiber, 0.5~1.0 parts Cellulose nanofibrils, 0.2-0.4 parts of glass fiber, 3-6 parts of surfactant and appropriate amount of water.

[0035] The surfactant is at least one of an anionic surfactant and an alkyl glycoside sulfonate, and the surfactant can effectively increase the surface tension of the granite particles, preventing it from being dissolved in the graphene hydrogel body of the graphene oxide sheet. Agglomeration, improve the dispersion effect of yellow granite particles.

Embodiment 2

[0051] The difference from Example 1 is that this example also provides a technical solution: a light-weight, high-strength, water-resistant decorative gypsum board, prepared from the following components in parts by weight: 70-80 parts of gypsum powder , 5-10 parts of diatomite, 1-3 parts of corn starch, 0.5-3 parts of foam stabilizer, 5-10 parts of granite particles, 3-5 parts of graphene oxide sheets, 3-5 parts of silicon acrylic emulsion, 0.3- 0.9 part of waste paper pulp fiber, 0.5-1.0 part of cellulose nanofibrils, 0.2-0.4 part of glass fiber, 3-6 parts of surfactant and appropriate amount of water.

[0052] The surfactant is at least one of anionic surfactants and alkyl glycoside sulfonates.

[0053] The foam stabilizer is azodicarbonamide, and the molecular formula of azodicarbonamide is: C2H4N4O2, which is foamed after the gypsum powder is stirred.

[0054] S1. Prepare the raw material components according to the amount, crush the gypsum powder raw material, input th...

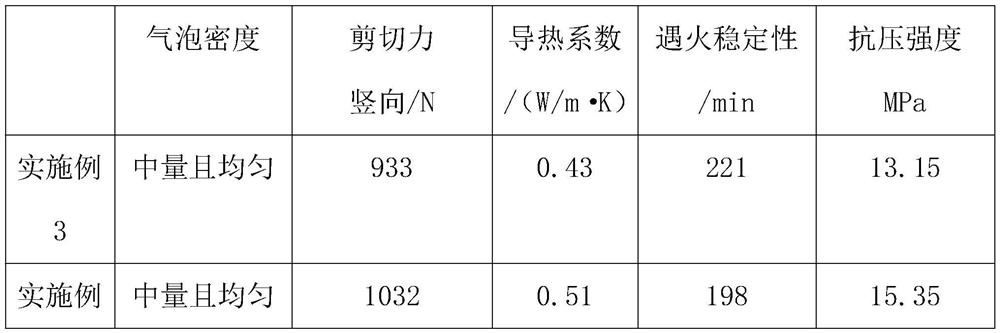

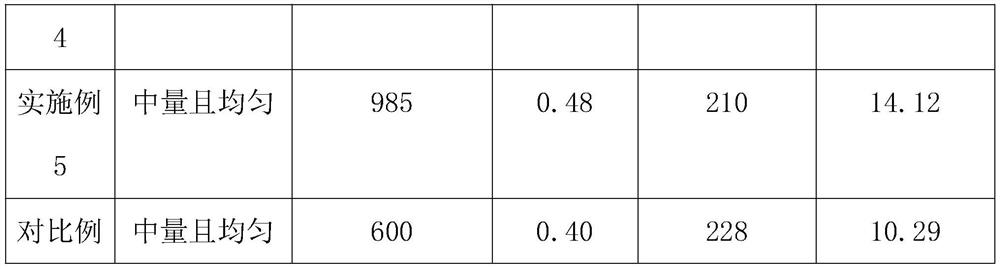

Embodiment 3

[0065] Different from the above-mentioned solution, this embodiment also provides a technical solution, a light-weight, high-strength, water-resistant decorative gypsum board, which is prepared from the following components in parts by weight: 70 parts of gypsum powder, 5 parts Parts of diatomite, 1 part of corn starch, 0.5 parts of foam stabilizer, 5 parts of granite particles, 3 parts of graphene oxide sheets, 35 parts of silicon-acrylic emulsion, 0.3-0.9 parts of waste paper pulp fibers, 0.5-1.0 parts of cellulose nanofibers Silk, 0.2-0.4 parts of glass fiber, 3-6 parts of surfactant and appropriate amount of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com