Foaming material applied to musical instrument box and preparation method thereof

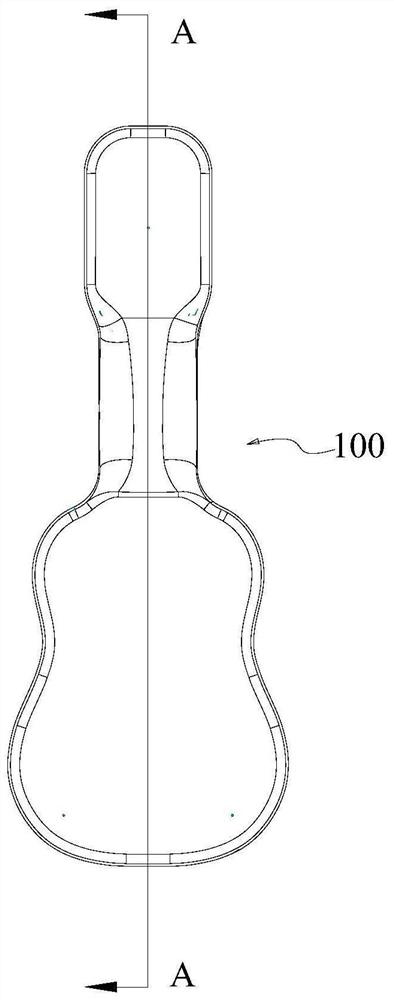

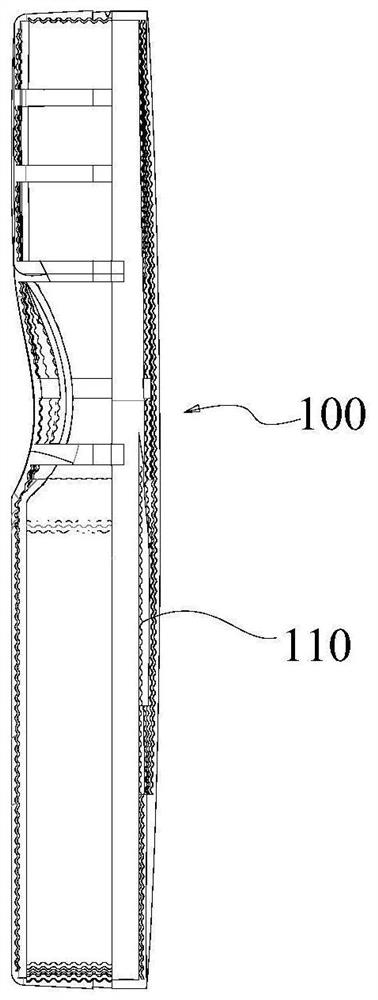

A foamed material and musical instrument box technology, applied in the field of musical instrument box manufacturing materials, can solve problems such as poor anti-collision performance of musical instrument boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The embodiment of the present invention also provides the above-mentioned preparation method of the foam material applied to the musical instrument case, comprising the following steps:

[0030] 1) Mix the proportioned amount of talc powder and silane coupling agent KH560 evenly, and place the mixed talc powder in an oven at 70-80°C for 2-4 hours for dehumidification treatment; finally sieve with a 100-120 mesh screen , to prepare modified talcum powder;

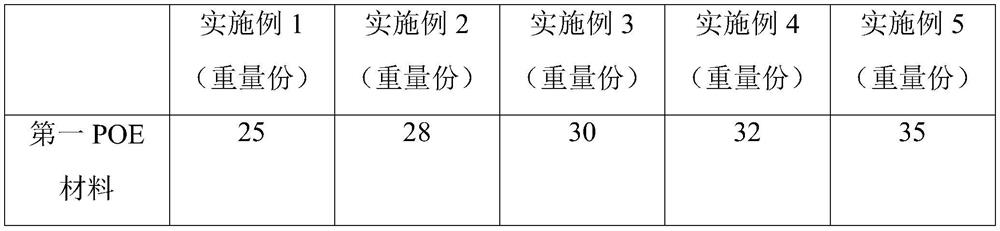

[0031] 2) Weigh the following raw materials according to the proportion: the first POE material, the second POE material, the third POE material, talcum powder, zinc oxide, lubricant, zinc stearate, wear-resistant agent, bridging agent and foaming agent, Mix the above raw materials and put them into a banbury mixer for banburying. The banburying time is 5-15 minutes, and the banburying temperature is 102-108°C to obtain the POE mixture;

[0032] 3) Add the POE mixture into the mill, the milling temperature is 90-95°C...

Embodiment 1-2

[0039] The preparation method of the foam material applied to the musical instrument case provided by embodiment 1-2 comprises the following steps:

[0040] 1) Mix the proportioning amount of talc powder and silane coupling agent KH560 evenly, and place the mixed talc powder in an oven at 70°C for dehumidification treatment for 4 hours; finally sieve it with a 100-mesh sieve to obtain the modified talcum powder;

[0041] 2) Weigh the following raw materials according to the proportion: the first POE material, the second POE material, the third POE material, talcum powder, zinc oxide, lubricant, zinc stearate, wear-resistant agent, bridging agent and foaming agent, Mix the above raw materials and put them into a banbury mixer for banburying. The banburying time is 5 minutes and the banburying temperature is 108°C to obtain the POE mixture;

[0042] 3) Add the POE mixture into the mill, the milling temperature is 90°C, the molding temperature is 170°C, and the pressure is 13Mpa...

Embodiment 3

[0044] The preparation method of the foam material applied to the musical instrument case provided by embodiment 3 comprises the following steps:

[0045] 1) Mix the proportioning amount of talc powder and silane coupling agent KH560 evenly, and place the mixed talc powder in an oven at 75°C for dehumidification treatment for 3 hours; finally sieve it with a 100-mesh sieve to obtain the modified talcum powder;

[0046] 2) Weigh the following raw materials according to the proportion: the first POE material, the second POE material, the third POE material, talcum powder, zinc oxide, lubricant, zinc stearate, wear-resistant agent, bridging agent and foaming agent, Mix the above raw materials and put them into a banbury mixer for banburying. The banburying time is 10 minutes, and the banburying temperature is 105°C to obtain the POE mixture;

[0047] 3) Add the POE mixture into the mill, the milling temperature is 93°C, the molding temperature is 175°C, and the pressure is 13.5M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com