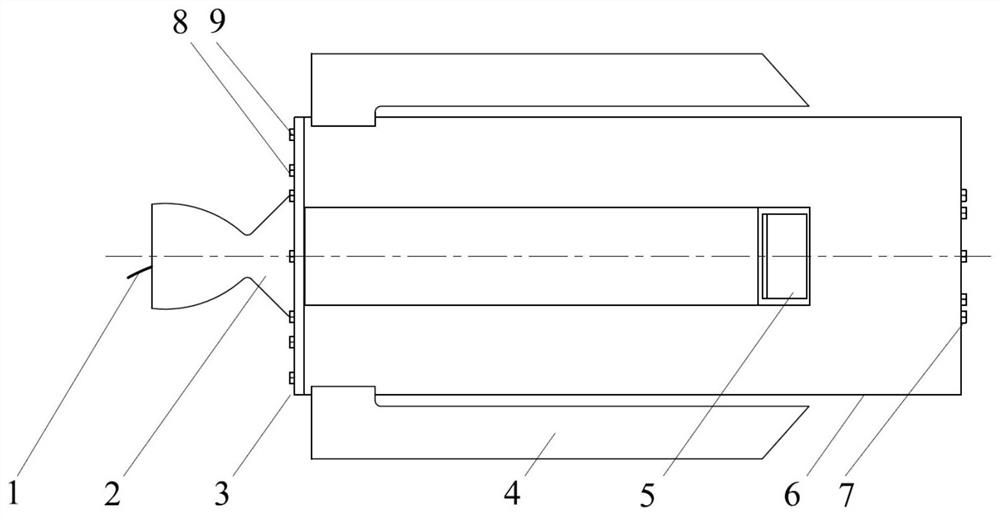

Phase change type paraffin-containing fuel ramjet engine

A ramjet, paraffin fuel technology, applied in ramjet engines, engine components, machines/engines, etc., can solve the problems of short residence time of high-speed incoming air, low combustion efficiency, and long engine size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

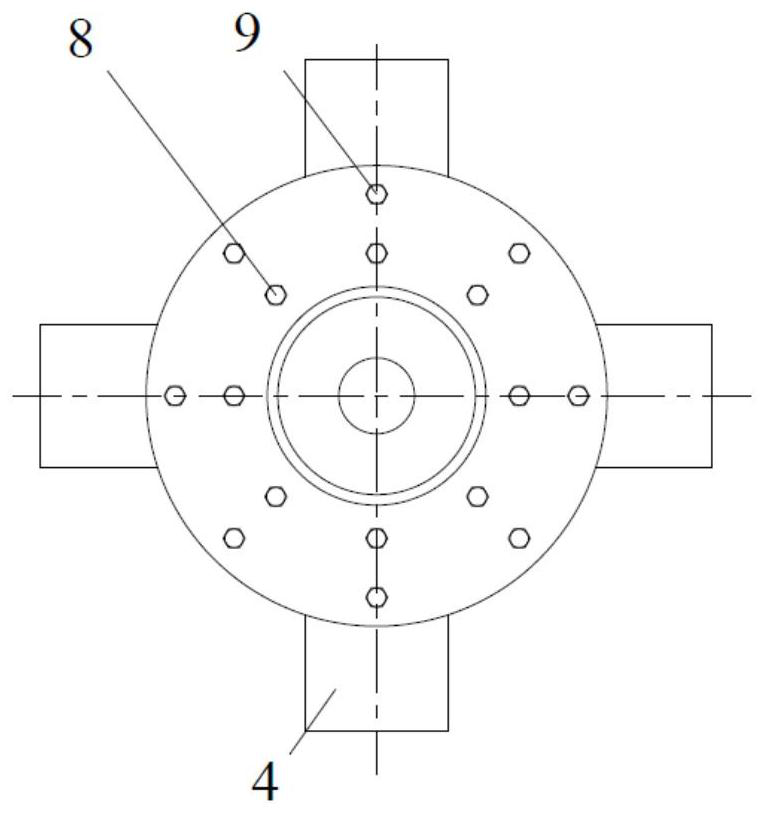

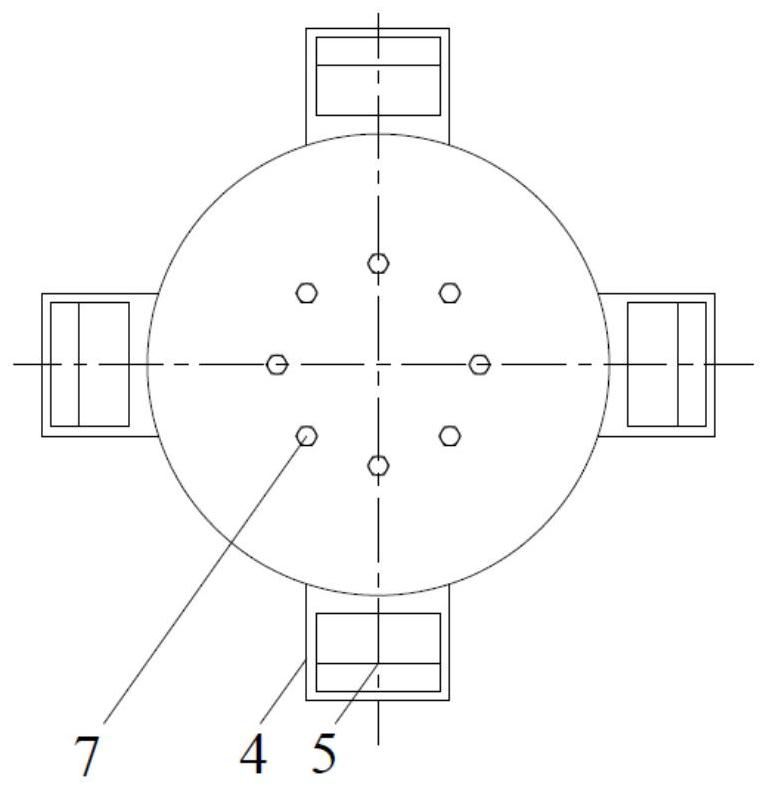

Method used

Image

Examples

example 1

[0047] Take 80% of paraffin wax, 10% of polyazide glycidyl ether, 5% of aluminum powder, 3% of toluene diisocyanate, and 2% of magnesium powder as raw materials by mass percentage to prepare tubular paraffin-containing fuel powder column, which is loaded in the form of free filling Gasification chamber: 70% of ammonium perchlorate, 10% of hydroxyl-terminated polybutadiene, 15% of aluminum powder, 3% of toluene diisocyanate, and 2% of magnesium powder are taken as raw materials by mass percentage to prepare tubular solid propellant grains , into the combustion chamber in the form of free filling.

[0048] After the engine and a certain type of product body are assembled, the igniter is energized, and the gas generated by deflagration ignites the solid propellant, and the solid propellant burns in the combustion chamber. After the gas is expanded and accelerated by the nozzle, the heat energy is converted into kinetic energy. Accelerate the missile. After accelerating to a cert...

example 2

[0050] According to mass percentage, 75% of paraffin wax, 15% of 3,3-diazidomethyloxybutane, 5% of aluminum powder, 3% of isophorone diisocyanate and 2% of magnesium powder are used as raw materials to prepare paraffin-containing fuel. Tube-shaped drug type is used, and it is loaded into the gasification chamber in the form of free filling; according to the mass percentage, 65% of ammonium perchlorate, 10% of hydroxyl-terminated polybutadiene, 20% of aluminum powder, 3% of isophorone diisocyanate, 2% magnesium powder is used as raw material to prepare solid propellant. It adopts cone-column powder type and is loaded into the combustion chamber in the form of free filling.

[0051] After the engine and a certain type of product body are assembled, the igniter is energized, and the gas generated by deflagration ignites the solid propellant, and the solid propellant burns in the combustion chamber. After the gas is expanded and accelerated by the nozzle, the heat energy is conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com