Modification water reduction agent for concrete

A water-reducing agent and concrete technology, applied in the field of water-reducing agents, can solve the problems of high viscosity and difficult mixing of the water-reducing agent, and achieve the effects of shortening the setting time, improving the laying, and improving the water-reducing rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

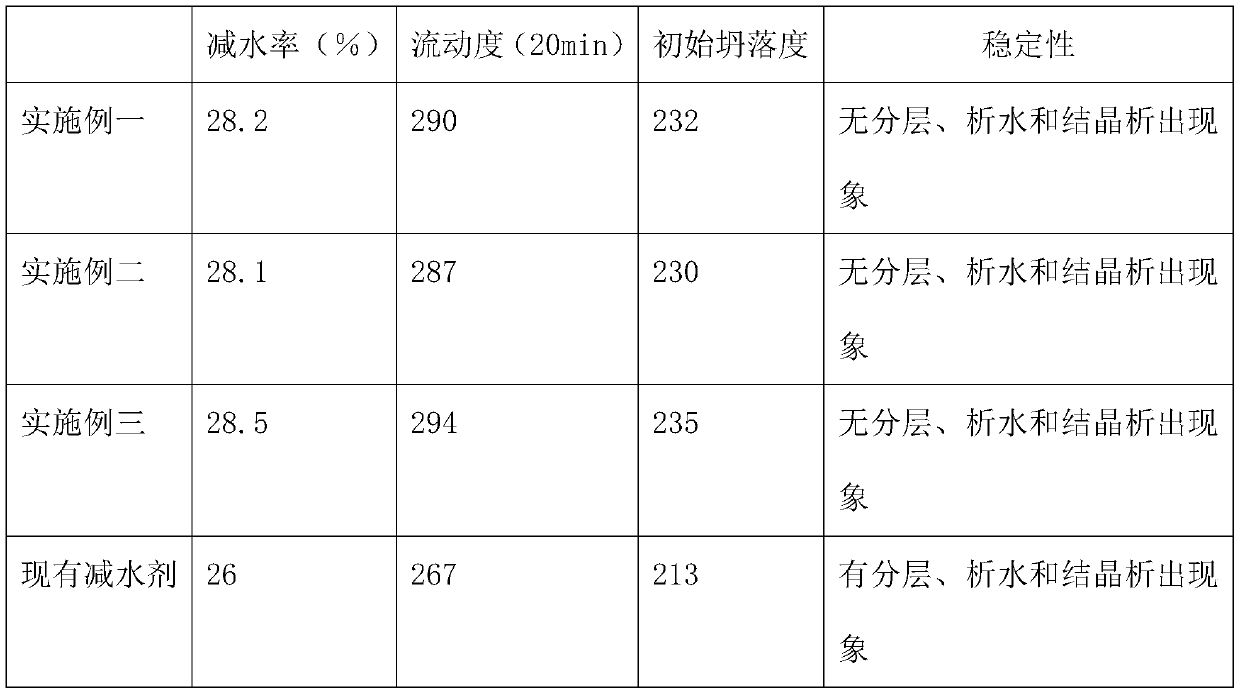

Examples

preparation example Construction

[0033] Further, the preparation method includes the following steps:

[0034] S1, adding β-naphthalene sulfonate sodium wastewater, polyvinylpyrrolidone and dodecylpyridinium bromide to the reactor for stirring;

[0035] S2: After stirring evenly, add acrylic acid, deionized water and benzoyl peroxide, heat up to 70 degrees and stir for 1 hour to obtain a sodium naphthalene sulfonate wastewater mixture;

[0036] S3, add methallyl polyoxyethylene ether, sulfite, 30% hydrogen peroxide and deionized water to the mixed solution, raise the temperature of the solution to 80 degrees, keep the solution warm and stir at a constant speed, the stirring time is 1h;

[0037] S4: Reduce the temperature of the mixture in the reactor to 50-60 degrees Celsius, and add water, modifier, viscosity modifier, early strength agent and air-entraining agent;

[0038] S5, keeping the temperature in the reaction kettle constant, stirring at a constant speed for 2 hours, and evacuating the reaction kettle to extr...

Embodiment 1

[0040] S1, adding 30 parts of methallyl polyoxyethylene ether, 10 parts of sulfite, 3 parts of 30% hydrogen peroxide and deionized water into the 25β-naphthalene sulfonate sodium wastewater mixture to raise the temperature of the solution to 80 degrees, Heat the solution and stir at a constant speed, the stirring time is 1h;

[0041] S2, reduce the temperature of the mixture in the reaction kettle to 50-60 degrees Celsius, add an appropriate amount of water, 4 parts of modifier, 5 parts of viscosity modifier, 7 parts of early strength agent and 8 parts of air-entraining agent;

[0042] S3, keeping the temperature in the reaction kettle constant, stirring at a constant speed for 2 hours, and evacuating the reaction kettle to extract excess water during the reaction process.

Embodiment 2

[0044] S1, adding 40 parts of methallyl polyoxyethylene ether, 15 parts of sulfite, 3 parts of 30% hydrogen peroxide and deionized water into the 30β-naphthalene sulfonate sodium wastewater mixture to raise the temperature of the solution to 80 degrees, Heat the solution and stir at a constant speed, the stirring time is 1.2h;

[0045] S2: Reduce the temperature of the mixture in the reaction kettle to 50-60 degrees Celsius, add an appropriate amount of water, 6 parts of modifier, 7 parts of viscosity modifier, 8 parts of early strength agent and 9 parts of air-entraining agent;

[0046] S3, keeping the temperature in the reaction kettle constant, stirring at a constant speed for 2 hours, and evacuating the reaction kettle to extract excess water during the reaction process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com