Ring cavity rotational flow opposite spraying structure based on RDE combustion chamber

A combustion chamber and annular cavity technology, applied in the field of annular cavity swirl counter-injection structure, can solve the problems of increased wall surface heating, unfavorable detonation wave stability, small coverage area of a single fuel injection hole, etc. Increase the contact area and reduce the effect of wall heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

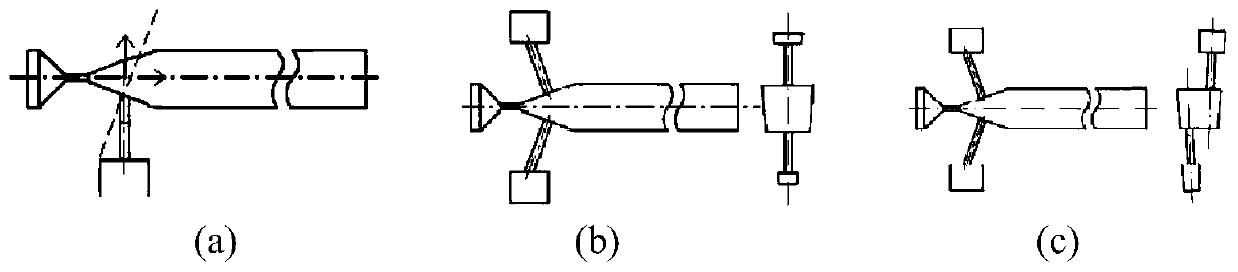

[0056] The overall design configuration of RDE is as follows Figures 4 to 5 shown.

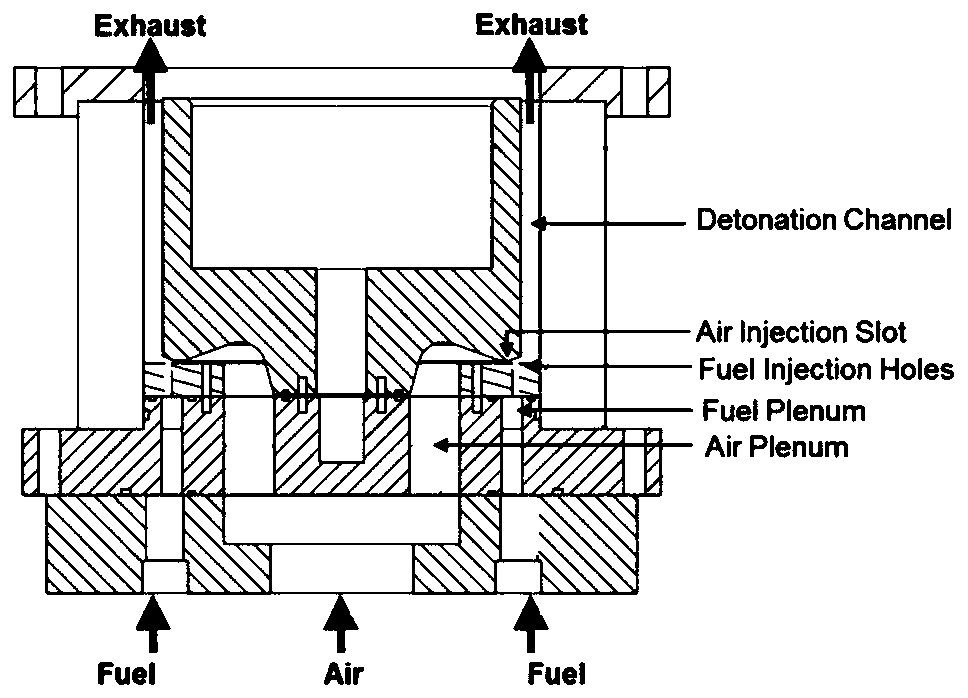

[0057] The coaxial annulus combustor structure of RDE is a known technology.

[0058] The process of the engine providing power can be understood as: fuel is mixed with air, and after mixing, it is burned in the combustion chamber, and the combustion products are ejected through the tail nozzle to generate thrust. The focus of this invention is on fuel / air blending.

[0059] The improvement that the present invention mainly makes is:

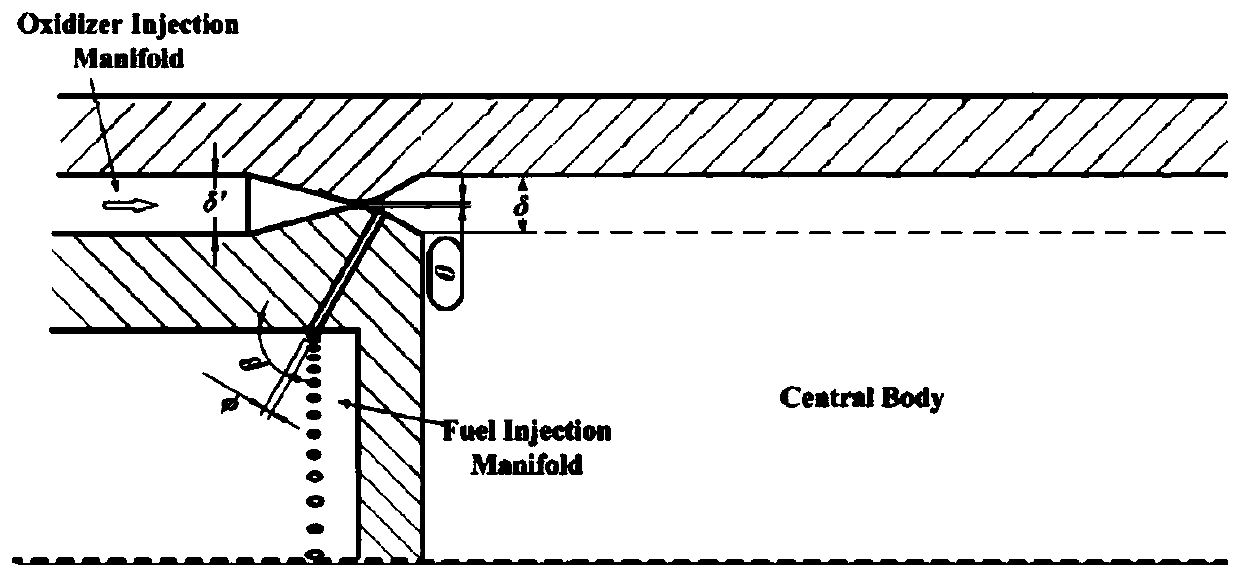

[0060] (1) Axisymmetric surface circular seam.

[0061] What prior art adopted is linear contraction and expansion annular seam, and the scheme of the present invention is curved surface (as Figure 5 Shown) Contraction and expans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com