Double-layer mixing pipe and residue-free mixing bin

A technology of mixing pipe and mixing materials, which is applied in the field of mixing silos, can solve the problems of inability to mix and discharge materials uniformly, uneven mixing of materials, and large vibration amplitude of the upper part, so as to achieve good product quality, uniform mixing of materials, and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

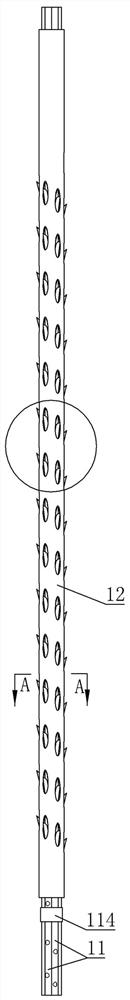

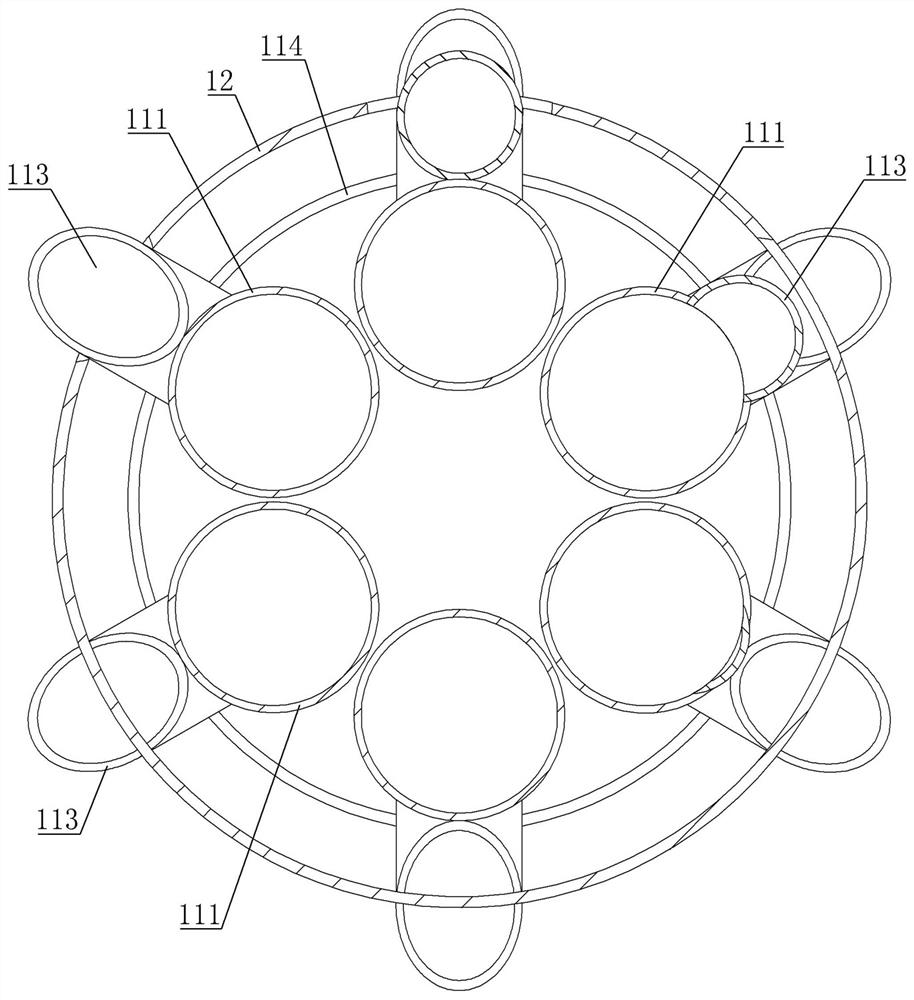

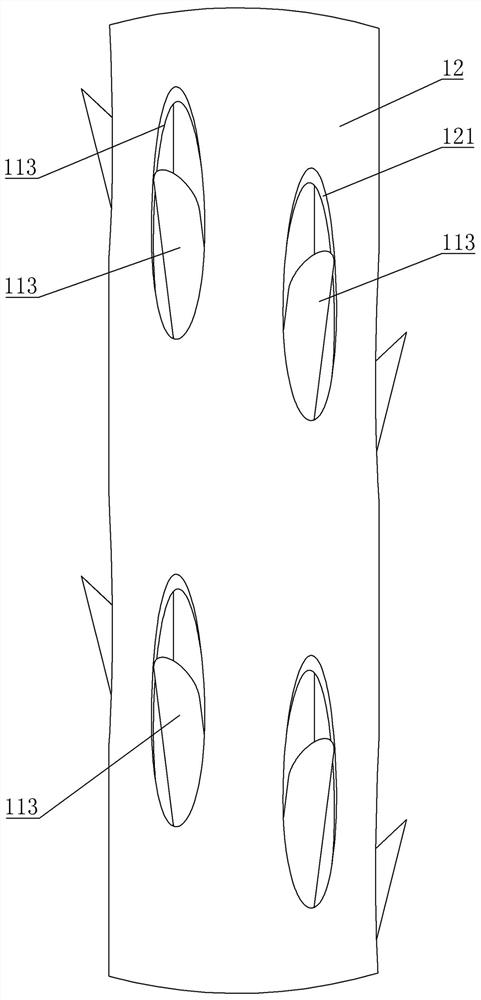

[0031] Embodiment 1, referring to the accompanying drawings 1-6 of the description, a double-layer blending material pipe, including an outer casing and a blending pipe, the outer side of the pipe wall of the blending pipe is provided with several feed holes at equal intervals along the direction of the busbar, correspondingly Adjacent feeding holes are staggered, and a group of feeding holes arranged in a spiral arrangement at equal intervals is formed on the wall of the mixing tube. This arrangement is more evenly distributed on the mixing tube, which is beneficial to the mixing of different batches of materials. The mixing pipe is discharged synchronously, and each feeding hole is fixedly connected with a feeding duckbill pipe inclined upward along the direction of the mixing pipe bus;

[0032] The outer casing is coaxially sleeved on the mixing pipe, and the size of the outer casing is larger than that of the mixing pipe. The pipe wall of the outer casing is provided with s...

Embodiment 2

[0034] Embodiment two, refer to the appended Figure 1-12, a non-residue blending silo, comprising a cylindrical silo with a conical silo bottom at the lower end, a collection silo coaxially fixed and set at the lower end of the conical silo bottom, the double-layer blending material described in claim 2 The lower part of the cylindrical silo is evenly distributed with a plurality of support seats.

[0035] The end cover of the cylindrical silo is evenly distributed with a plurality of vibration support components near the outer edge. The components include a cylindrical bracket vertically fixed on the surface of the end cover, a vibrator, a shock spring, and an end cover covered by the cylindrical bracket. A through hole is provided at the center, and the cushioning spring is set on the outside of the cylindrical bracket. The lower part of the outer surface of the cylindrical bracket is provided with an annular boss supported on the lower end of the cushioning spring. The up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com