Exhaust mixing method of refiling pneumatic ribbed jet pipe and device thereof

A linear and protruding technology, applied in the direction of jet propulsion devices, machines/engines, etc., can solve the problems of inflexible adjustment of blenders, difficulties in processing and manufacturing, and flow loss of nozzles, so as to improve applicability, flexibility, and airflow The effect of abundant sources and excellent blending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

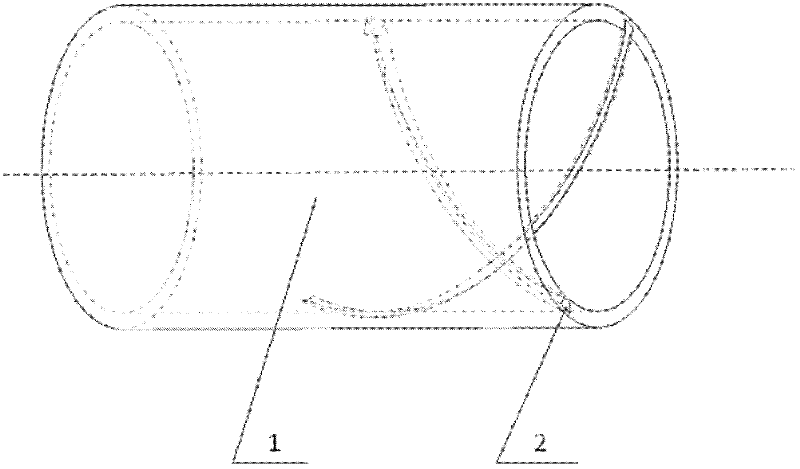

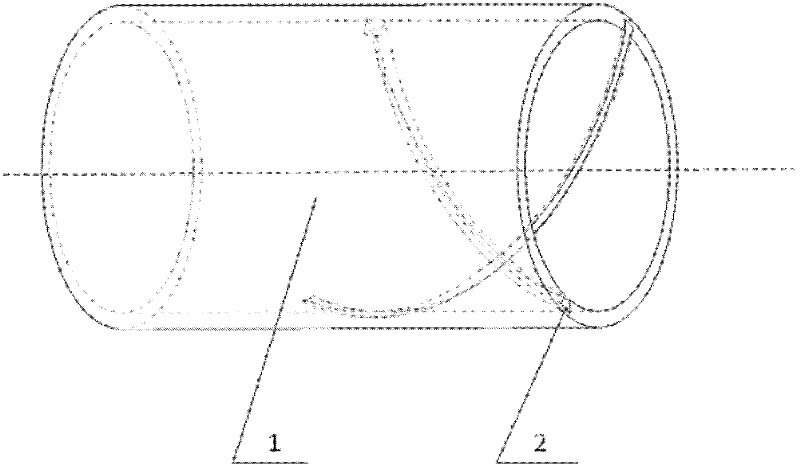

[0018] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] Such as figure 1 As shown, it discloses a rifling-shaped pneumatic protruding nozzle exhaust mixing device according to the present invention, including the main nozzle of the engine, and the outlet position of the main nozzle of the engine can be installed near the main nozzle of the engine. The aerodynamic protruding bar that sprays the rifled cylindrical jet in the main flow area of the main stream, the aerodynamic protruding bar includes a rifled jet injection zone and a jet control mechanism that automatically controls the injection flow rate of the rifled jet injection zone according to the actual working conditions of the engine. The rifled jet injection zone is set on the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com