Water-soluble environmental-protection composite printing ink and preparation method thereof

A water-soluble, water-soluble acrylic technology, used in inks, household appliances, applications, etc., can solve the problems of performance and printing performance defects, water-based ink adhesion fastness, initial drying does not achieve the effect of oil-based inks, etc., to reduce misfires The effect of hidden danger, good mixability and convenient cleaning of printing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

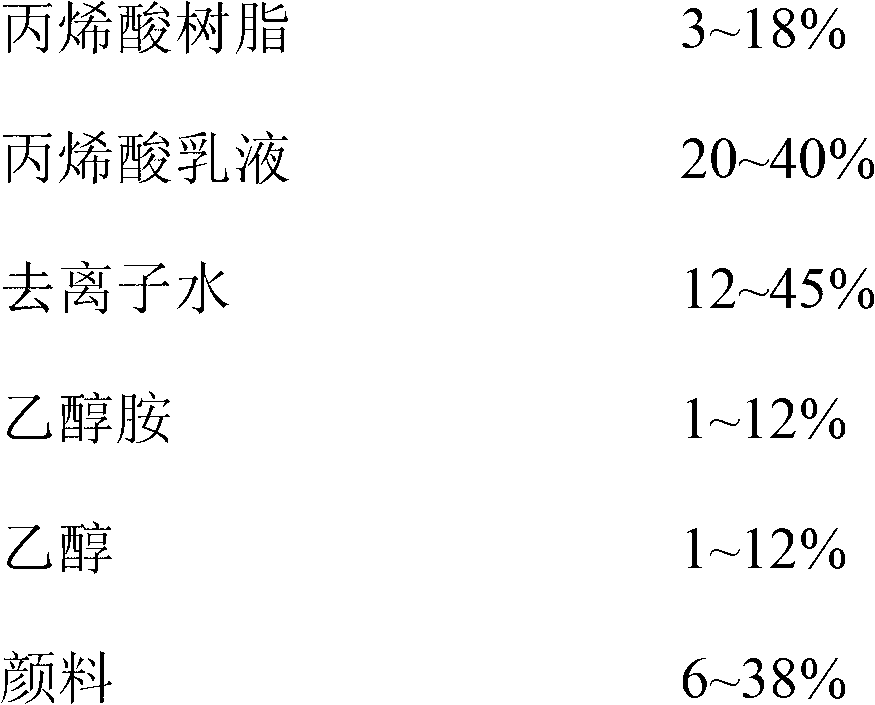

Method used

Image

Examples

Embodiment 1

[0064] Preparation:

[0065] (1) Preparation of resin solution: Add water-soluble acrylic resin, ethanolamine, ethanol, and deionized water into the resin dissolution kettle according to the formula ratio, and prepare the resin solution at a temperature of 50~60°C;

[0066] (2) Wetting and dispersing of pigments: Take the prepared resin solution and pigments according to the formula ratio and add them to the dispersing mixer for wetting and dispersing of the materials, and the stirring time is about 30~40 minutes;

[0067] (3) Stirring and grinding of pigments: After cooling the dispersed materials to 30~40°C, finely grind and disperse them through grinding equipment, and use mechanical external force to grind the pigments into fine particles until the fineness of the materials is ≤ 10μm;

[0068] (4) Further dispersion of materials: After the ink reaches a fineness of ≤10 μm, add pH stabilizer, anti-sedimentation agent, adhesion enhancer and self-crosslinking acrylic emulsio...

Embodiment 2

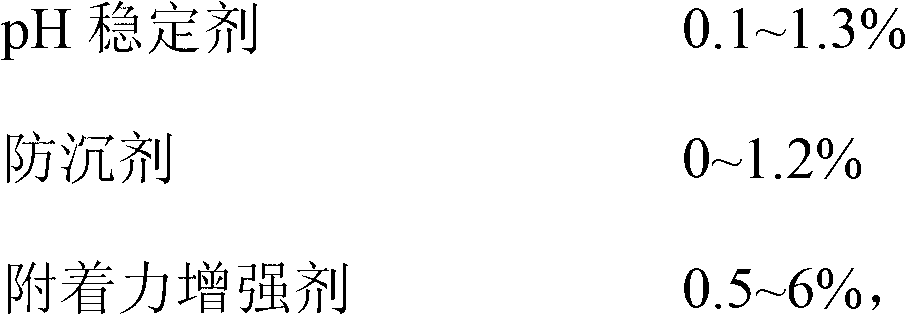

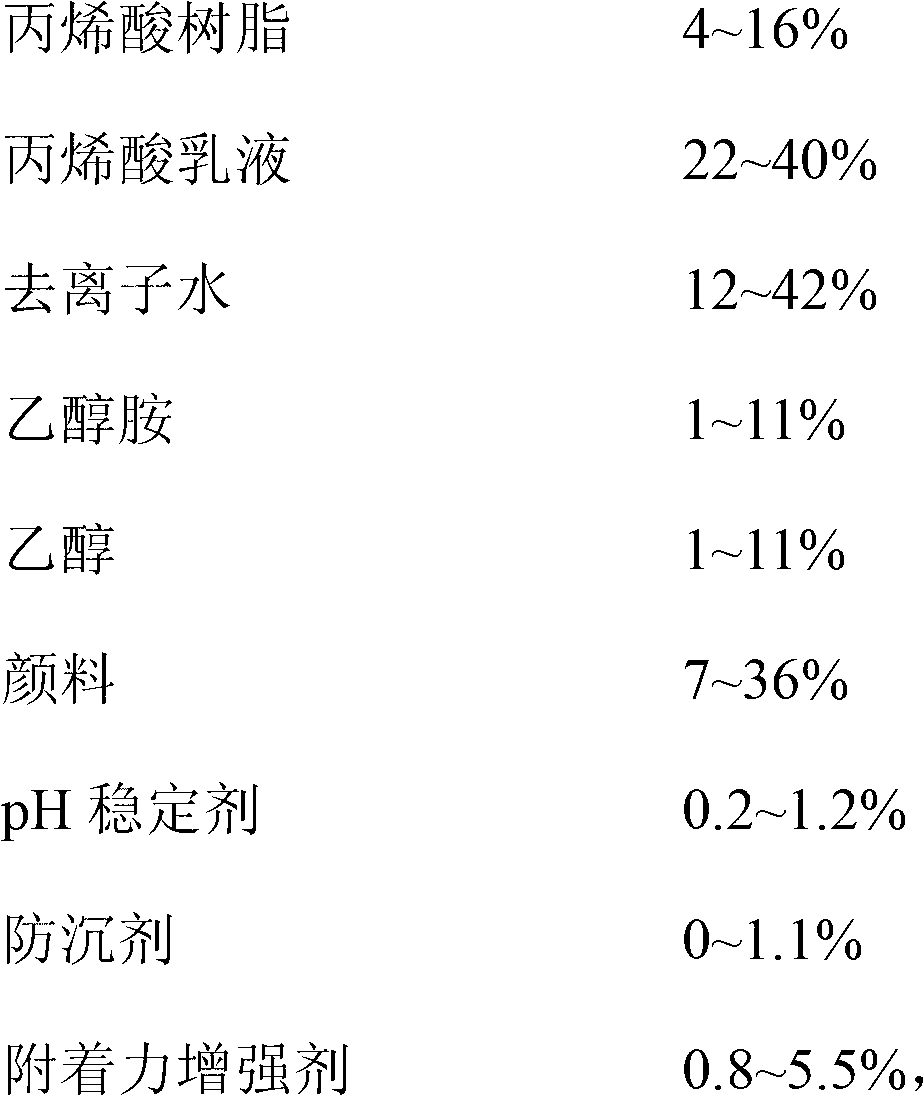

[0074] The colored water-soluble environment-friendly composite ink includes by weight percentage:

[0075]

[0076] The preparation method of the composite ink is the same as in Example 1.

Embodiment 3

[0078] The composition of described composite ink is identical with embodiment 1.

[0079] The preparation method of described composite ink is:

[0080] (1) Preparation of resin solution: Add water-soluble acrylic resin, ethanolamine, ethanol, and deionized water into the resin dissolution kettle according to the formula ratio, and prepare the resin solution at a temperature of 50~60°C;

[0081] (2) Wetting and dispersing of pigments: Take the prepared resin liquid and pigments and add them into the dispersion mixer according to the formula ratio to carry out the wetting and dispersing of the materials, and the stirring time is about 25-35 minutes;

[0082] (3) Stirring and grinding of pigments: After cooling the dispersed materials to 30~40°C, finely grind and disperse them through grinding equipment, and use mechanical external force to grind the pigments into fine particles until the fineness of the materials is ≤ 10 μm is enough.

[0083] (4) Further dispersion of mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com