Plastic gravure waterborne ink

A water-based ink, gravure technology, used in inks, household appliances, applications, etc., can solve the problems of alkali resistance, water resistance, poor adhesion, etc., to reduce residual pollutants on the surface, fast drying, and strong adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

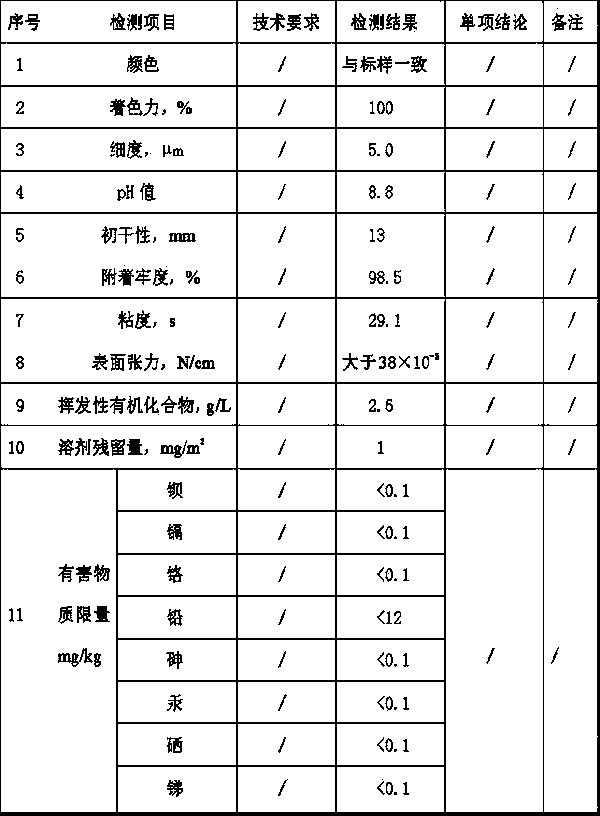

Image

Examples

Embodiment Construction

[0014] Below is an embodiment of the present invention-plastic gravure water-based ink, and it is by the component of following weight ratio:

[0015] 30 parts of polyamide, 10 parts of acrylic acid monomer, 10 parts of soybean oil, 2 parts of pentaerythritol, 11 parts of maleic anhydride, 0.03 part of magnesium oxide, 35 parts of rosin, 2 parts of crosslinking agent to prepare water-soluble synthetic resin, polyamide Select unsaturated diamine maleic anhydride, C 16 Dimer acid reaction synthesis, polyamide with molecular weight less than 10,000 containing unsaturated bonds; components in the following weight ratio: 48 parts of water-soluble synthetic resin, 17 parts of ethanol, 35 parts of water, 4 parts of ammonia water to prepare water-soluble Resin oil; components according to the following weight ratio: 55 parts of water-soluble resin oil, 20 parts of pigment, and 15 parts of water, composed of active agent, defoamer, stabilizer, dispersant, leveling agent, and slip agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com