A kind of preparation method of low-fluorine Antarctic krill hydrolyzed protein powder

A technology for hydrolyzing protein and Antarctic krill, which is applied in protein food ingredients, fish protein ingredients, food science, etc., can solve problems such as excessive heavy metal content, high salt content in protein powder, and non-compliance with food production requirements and specifications. , to achieve the effect of convenient operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

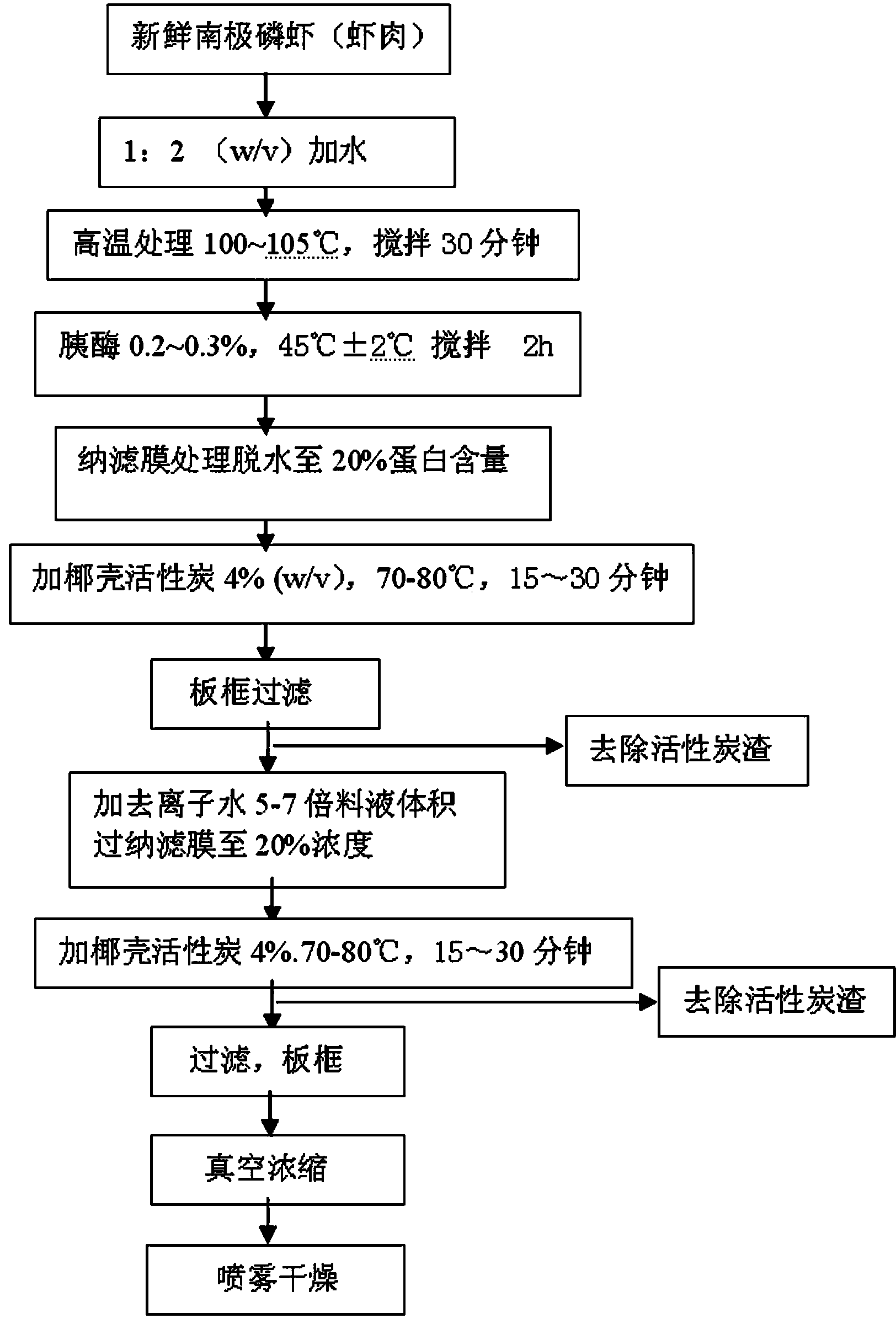

Image

Examples

Embodiment 1

[0009] (1) Take 1,000g of fresh Antarctic krill meat and place it in a reactor, add 2,000g of water, stir and heat in the reactor to 100-105°C, and keep it for 30 minutes.

[0010] (2) After reducing the liquid temperature to 45°C±2°C, add 0.2% trypsin, stir for 2 hours for constant temperature hydrolysis, raise the temperature to 95°C±2°C, and keep it for 20 minutes to inactivate the enzyme activity.

[0011] (3) Release the feed liquid, separate the slag liquid with a plate and frame filter, and filter out impurities and insoluble matter.

[0012] (4) The filtered feed liquid is dehydrated with nanofiltration membrane GE roll-type Ro membrane 1812 until the protein concentration in the feed liquid reaches 20%±2%.

[0013] (5) Add 4% (w / v) coconut shell activated carbon, raise the temperature to 75°C±2°C, and stir for 15 minutes.

[0014] (6) The feed liquid is filtered through a plate and frame filter to separate coconut shell activated carbon.

[0015] (7) Slowly add 5-7 ...

Embodiment 2

[0021] (1) Take 1000g of fresh Antarctic krill and 2000g of water, place them in a reaction kettle, stir and heat to 105°C±2°C, and keep for 30 minutes.

[0022] (2) Lower the temperature of the feed liquid to 45°C±2°C, add 0.2%-0.5% papain by weight of fresh Antarctic krill, and stir for 2 hours for constant temperature hydrolysis.

[0023] (3) Heat the hydrolyzate to 95°C±2°C. Leave for 15 minutes to inactivate the enzyme.

[0024] (4) Release the feed liquid, separate it with a centrifuge, and remove the shrimp shell and unhydrolyzed residue.

[0025] (5) The feed liquid is dehydrated once with a reverse osmosis membrane, and then concentrated to a feed liquid protein concentration of 20%±2% with a nanofiltration membrane GE roll-type Ro membrane 1812.

[0026] (6) Add coconut shell activated carbon 4% (w / v), heat up to 75°C±2°C, and stir for 15 minutes.

[0027] (7) The feed liquid is filtered with a plate and frame filter.

[0028] (8) Add 5 to 7 times of deionized wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com