Feeding inlet structure for biomass energy fuel boiler

A biomass energy and fuel import technology, applied in the direction of fuel supply, incinerator, combustion method, etc., can solve the problems of high cost of the whole system, difficult to achieve comprehensive utilization of ash and slag, and achieve the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

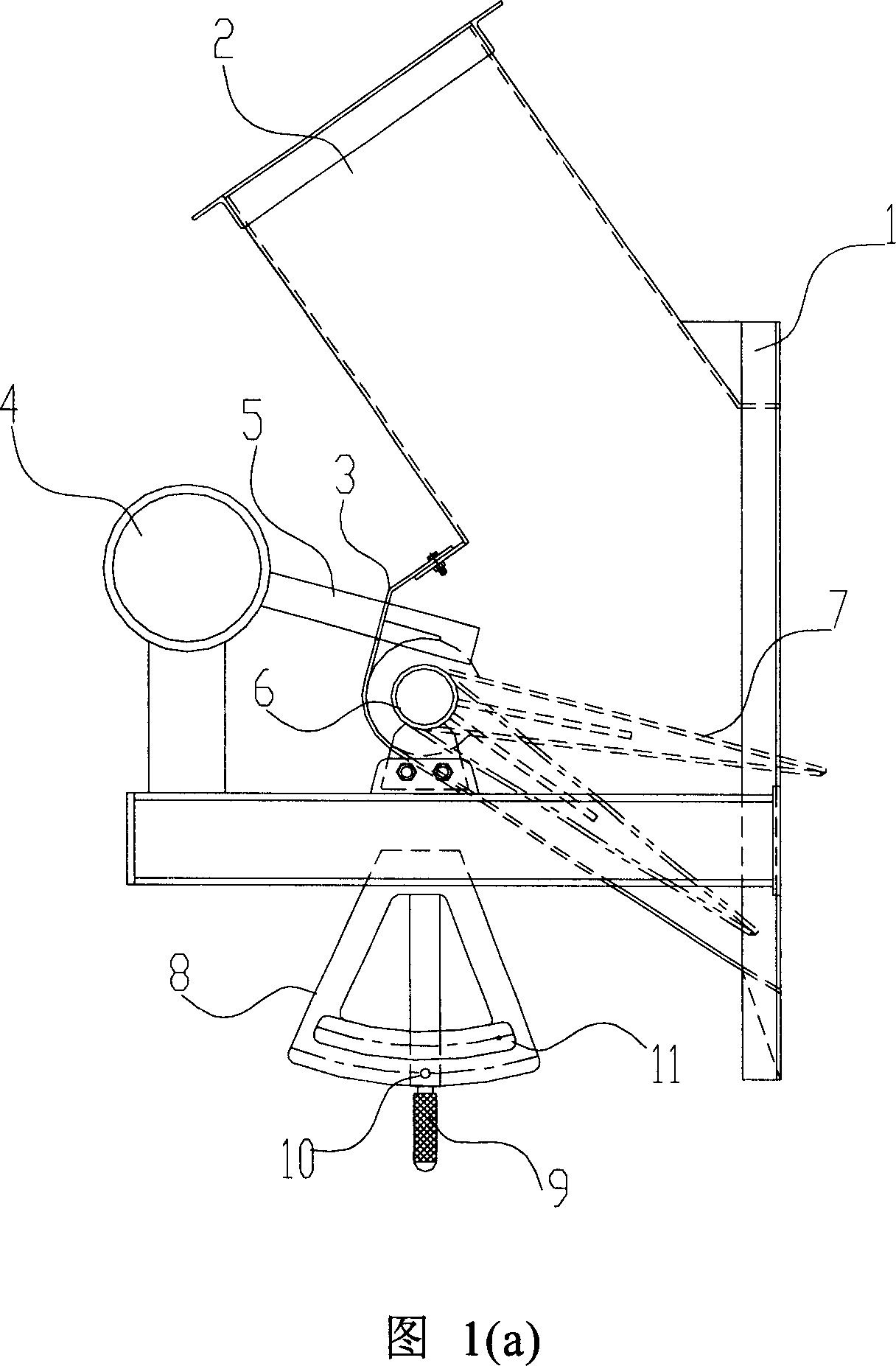

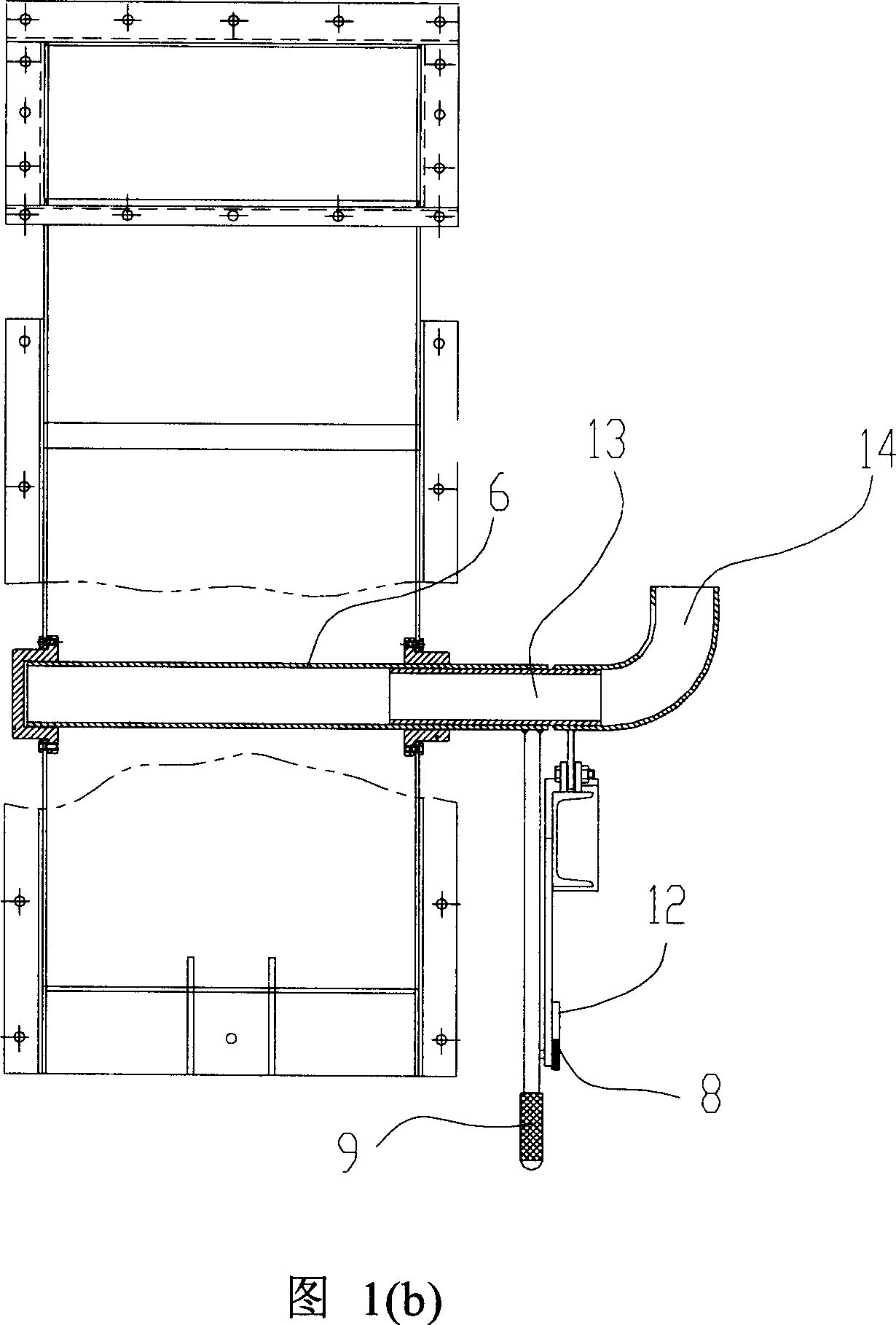

[0019] The gist of the invention is: (1) using wind force to send fuel into the furnace; (2) through adjustment, the fuel can be distributed more uniformly in the width direction of the fire grate; (3) cooling the feed inlet.

[0020] As shown in Figure 1(a), the compressed biomass fuel (straw) crushed into flakes, granules or powders is fed into the furnace of the boiler through the structure of the feed port of the present invention, and it is arranged in the furnace of the boiler. The front wall 1 of the furnace includes an upper part, a lower part and an adjustment mechanism. The adjustment mechanism is used to control the angle at which the fuel enters the furnace.

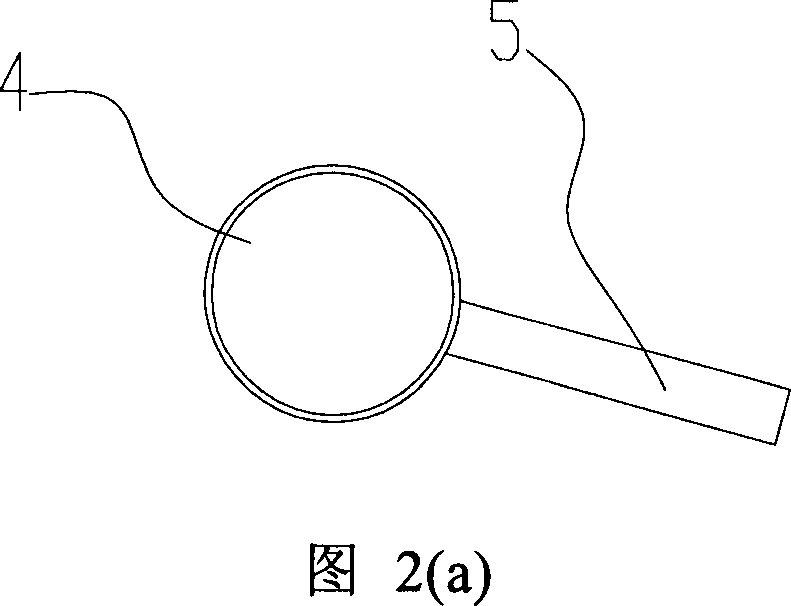

[0021] The upper part is an inclined fuel inlet structure, which includes a fuel inlet pipe 2 arranged at a predetermined angle with the furnace front wall 1 and a protruding part 3 that expands outwards outside the lower side of the fuel inlet pipe 2 .

[0022] The size of the inlet of the fuel inlet pipe 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com